A kind of photoelectric composite cable for 5g and its preparation device

A technology of photoelectric composite cable and preparation device, which is applied in cable/conductor manufacturing, insulated cable, communication cable, etc., can solve the problems such as the inability to maintain the same thickness of the plastic protective skin, the inability to cut the plastic protective skin, and the lack of a cutting mechanism. To achieve the effect of safe and convenient use, improved quality, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

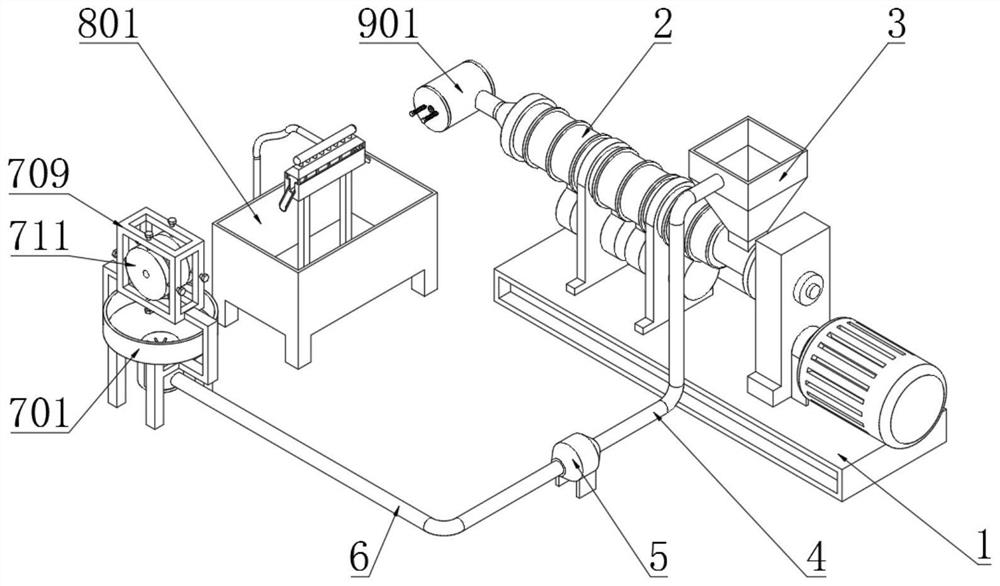

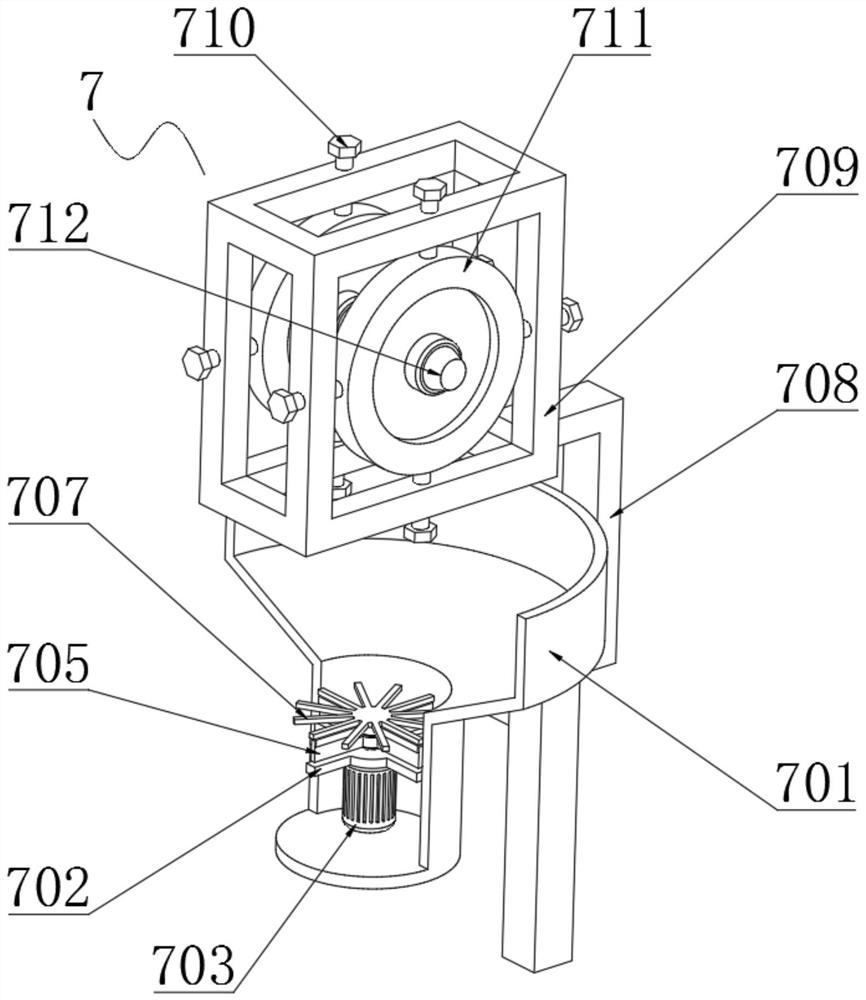

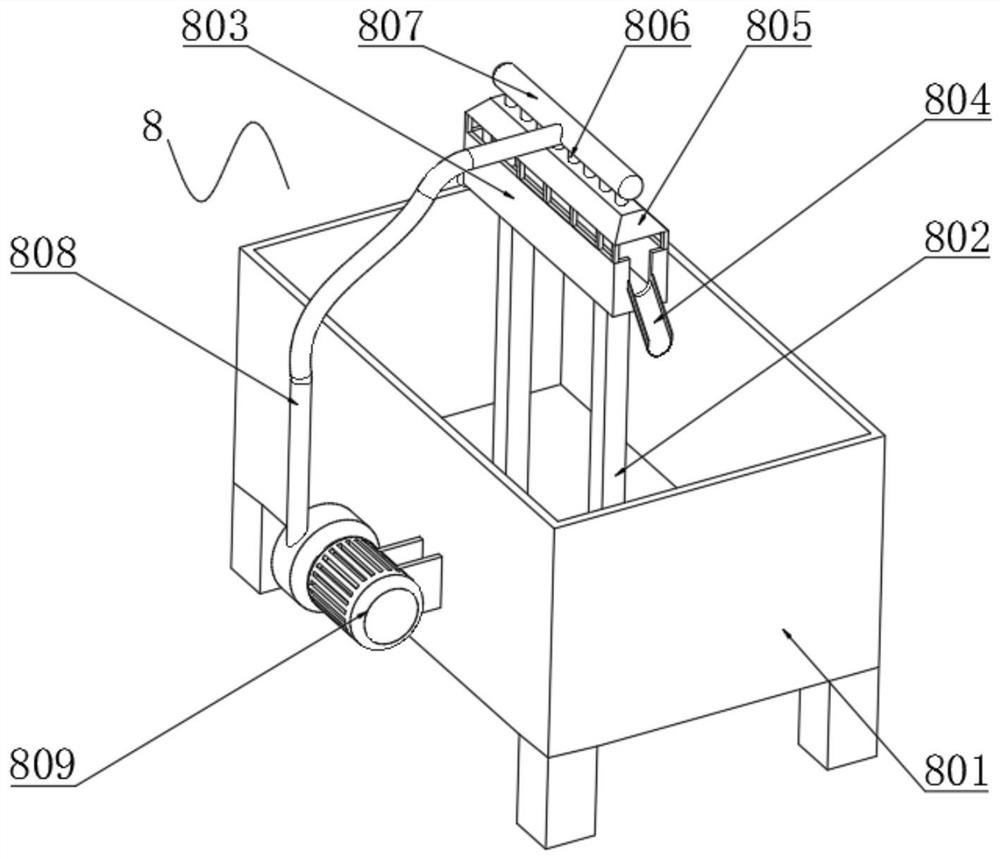

[0038] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a device for preparing a photoelectric composite cable for 5G, including a base 1, an extruder body 2 is fixedly installed on the top of the base 1, and an additional material is fixedly connected to the top side of the extruder body 2 Funnel 3, the top of one side of feeding funnel 3 is fixedly connected with feeding pipe 4, one end of feeding pipe 4 is fixedly connected with feeding fan 5, the model of feeding fan 5 is YINGDA PYHL-14, the input end of feeding fan 5 is connected to the mains One end of the feeding fan 5 is fixedly connected with a feeding pipe 6, and one end of the feeding pipe 6 is fixedly connected with a cutting mechanism 7, and the cutting mechanism 7 includes a collecting funnel 701, a mounting frame 702, a cutting motor 703, and a rotating block 704 , rotating knife bar 705, rotating blade 706, fixed blade 707, connecting frame 708, knife rest 709, fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com