Control structure and control method of Kaibel dividing wall rectifying tower

A technology of dividing wall rectification tower and control structure, which is applied in the field of control structure and control of separating multi-component mixture in Kaibel dividing wall rectification tower, which can solve problems such as poor control effect and product purity deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 The control structure of a kind of Kaibel rectification column with dividing wall

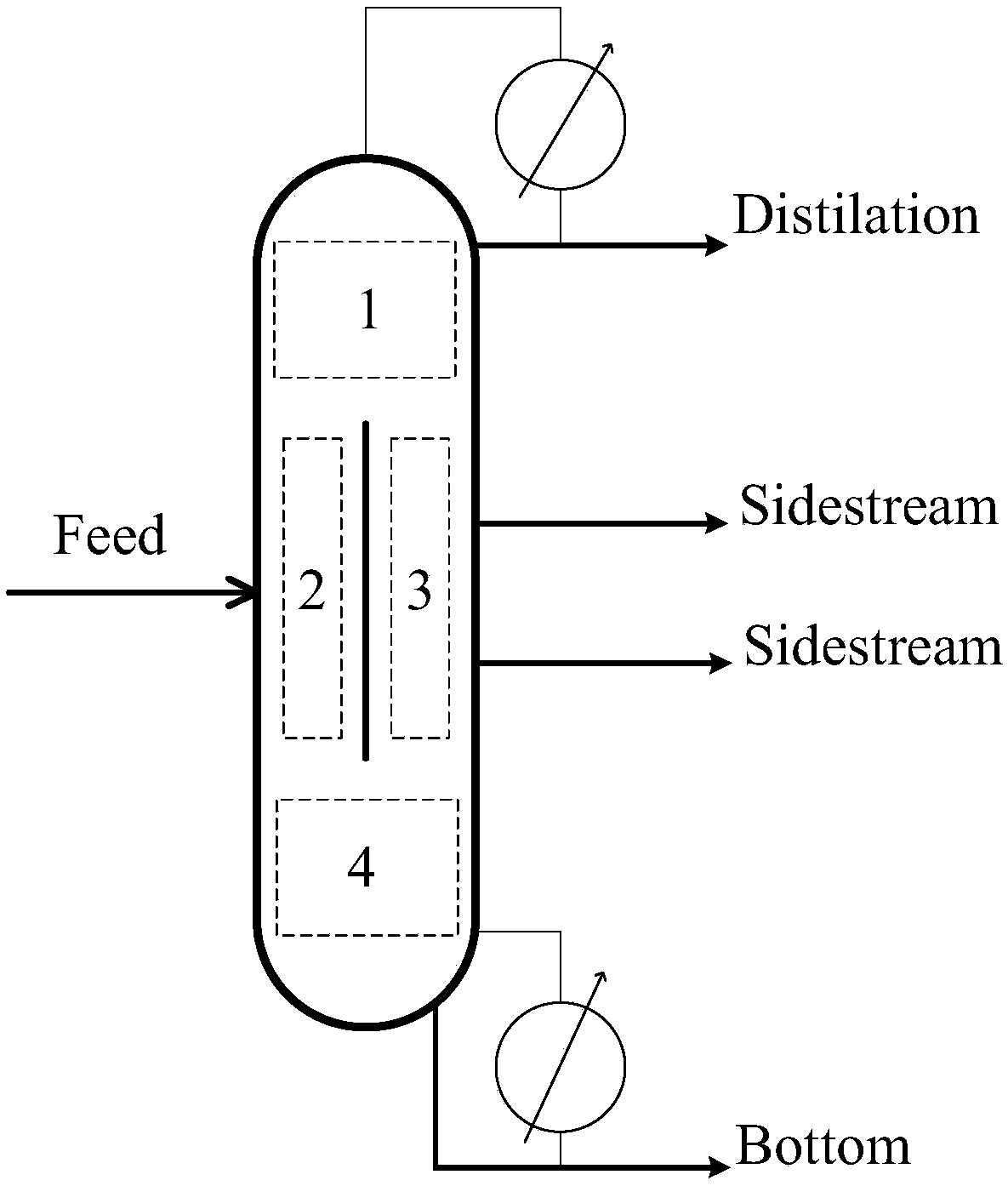

[0036] figure 1 It is a schematic diagram of the structure of a Kaibel dividing wall distillation column for separating a mixture of quaternary components. In the figure, the area marked "1" is generally called the rectification section, the area marked "2" is generally called the pre-fractionation section, and the area marked "3" is generally called the side line section, marked " The 4" area is generally called the stripping section. Areas "1", "3", and "4" are collectively called the main tower. The mixture is fed from the pre-fractionation section, the light components are extracted from the top of the rectification section, the middle components are extracted from the side line section, and the heavy components are extracted from the tower kettle.

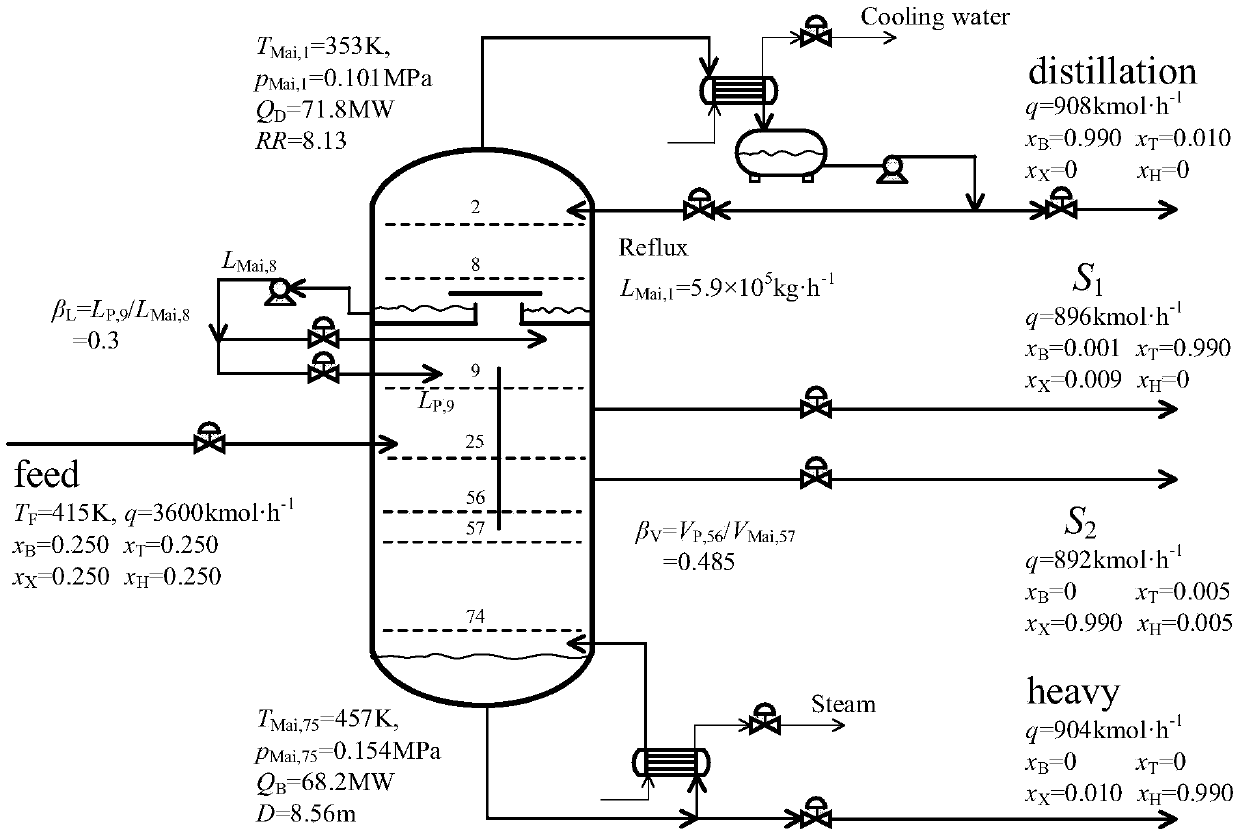

[0037] Take the separation of the quaternary mixture of benzene-toluene-xylene-mesitylene by using the dividing wall re...

Embodiment 2

[0045] Embodiment 2 A kind of control method of Kaibel rectification column with dividing wall

[0046] The quaternary mixture of benzene-toluene-xylene and mesitylene was separated by using the Kaibel dividing-wall rectification column with the control structure described in Example 1. The light component benzene is extracted from the top of the tower, the middle component toluene and xylene are extracted from the upper side line and the lower side line respectively, and the heavy component mesitylene is extracted from the tower kettle.

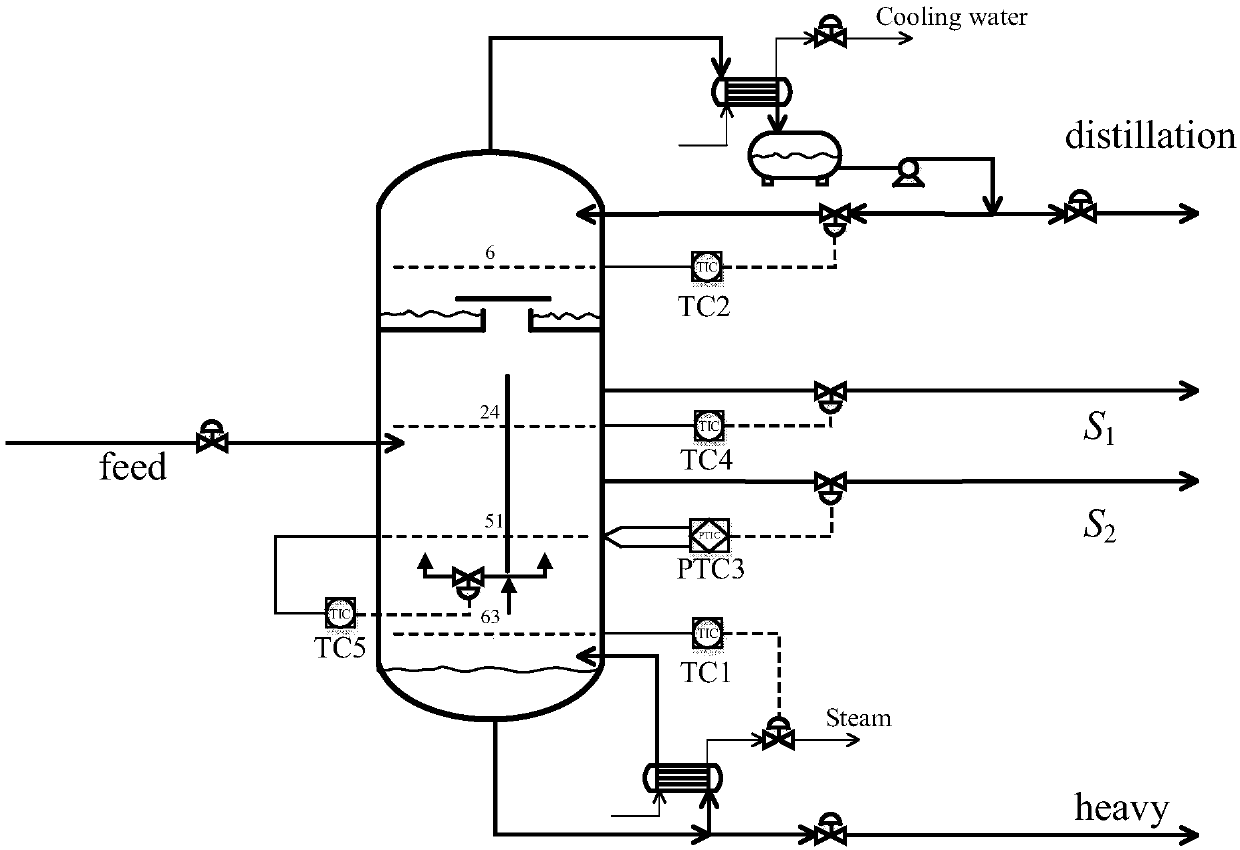

[0047] The TC2 control loop controls the temperature of the sensitive plate M6 in the rectification section through the return flow at the top of the tower, so as to ensure the purity of benzene at the top of the tower; the TC4 control loop controls the temperature of the sensitive plate M24 above the side line section through the output flow of the upper side line, so as to ensure the purity of the upper side line The product toluene purity...

Embodiment 3

[0059] The quaternary mixture of benzene-toluene-xylene-mesitylene is separated by using the Kaibel dividing-wall rectification column with control structure in Example 1. After the dividing wall rectification column operated stably for 2 hours, the concentration of toluene in the feed was disturbed by ±25%, from the original 25mol% to 31.25mol% or 18.75mol%. Figure 5 is the variation of the purity of the four products. It can be seen from the figure that under this control method, after the toluene component concentration in the feed is disturbed by ±25%, the purity of the toluene product returns to a stable level after about 8 hours, returning to 0.9902 and 0.9892, with a residual difference of less than 0.5%. The purity of other products is qualified. This shows that the control structure can well deal with the disturbance of ±25% incoming toluene concentration, and has good robustness and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com