Remediation device for soil contamination

A soil pollution and soil technology, applied in the field of soil remediation, can solve the problems of low soil treatment efficiency, unfavorable operation, complicated mechanical structure, etc., and achieve the effect of low treatment cost, reduced remediation cost and high remediation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

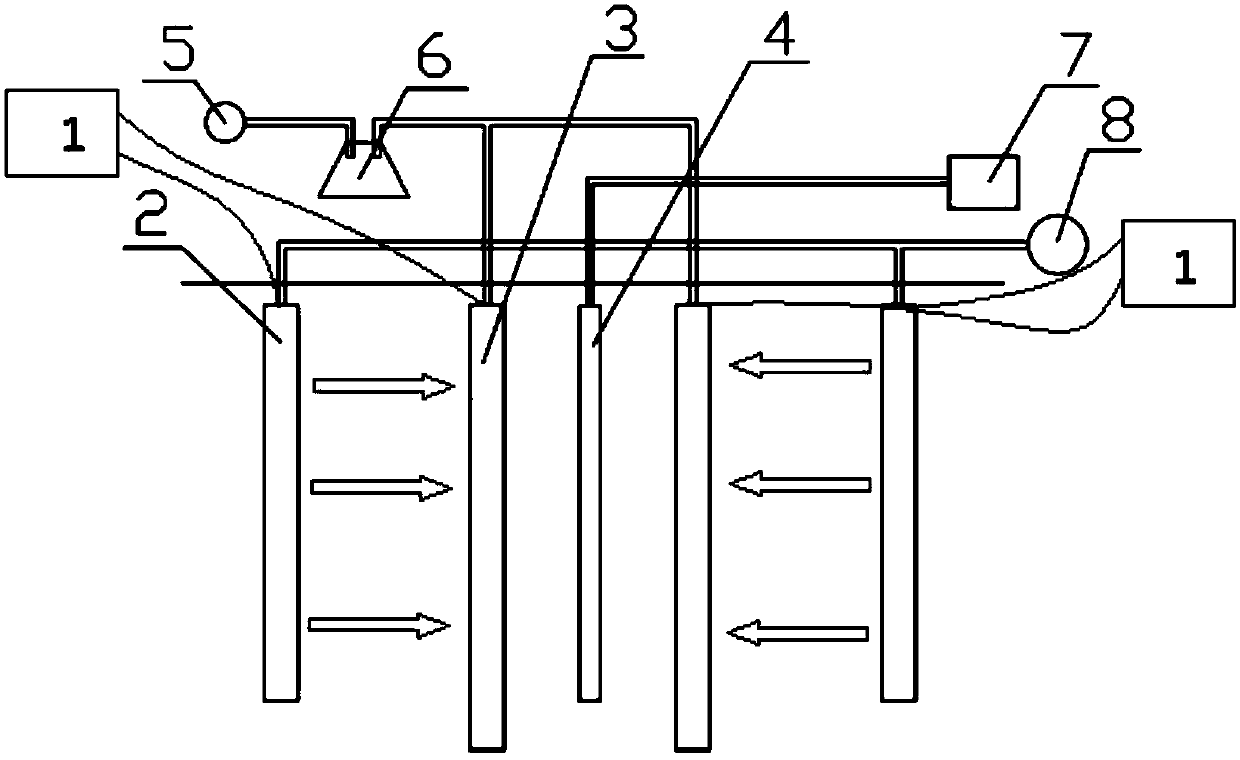

[0036] refer to figure 1, a soil pollution remediation device, which is a device for in-situ remediation of soil, the device includes a power supply 1, a freezer 7, a liquid injection pump 8, a vacuum pump 5, a steam-water separator 6 and a freeze-thaw rinse unit, the freeze-thaw rinse unit includes Two liquid injection and drainage plates 2, two liquid suction and drainage plates 3 and one freezing pipe 4, the two liquid suction and drainage plates 3 are symmetrically arranged on the outside of the freezing pipe 4 with the freezing pipe 4 as the center, and the two liquid injection and drainage plates 2 are The freezing pipe 4 is symmetrically arranged on the outside of the pumping and draining plate 3. The refrigerator 7 is connected to the freezing pipe 4 through a pipeline, and the liquid injection pump 8 is connected to the top of the liquid filling and draining plate 2 through a pipeline. The pipeline is connected to the steam-water separator 6, and the steam-water separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com