Roadside supporting method through high-water packing props

A high-water and prop technology, which is applied in prop/support, earthwork drilling, mining equipment, etc., can solve the problem that the service life and strength of the hydraulic support cannot meet the requirements of permanent support, the service life of a single hydraulic prop is not long enough, and the underground hydraulic prop Corrosion and other problems, to avoid overload leakage, good support effect and stable support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

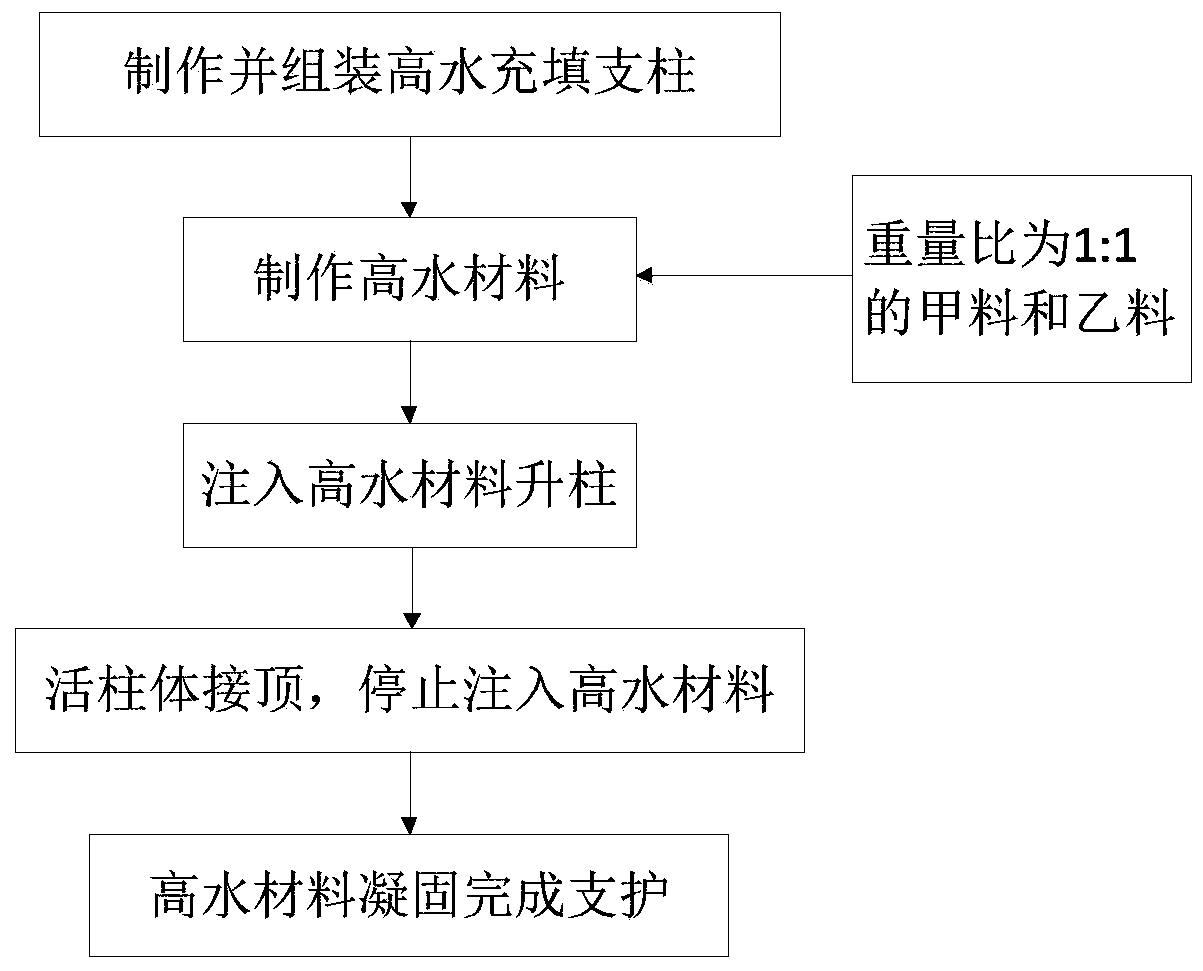

[0032] A high water filling pillar roadside support method, such as figure 1 As shown, the steps include:

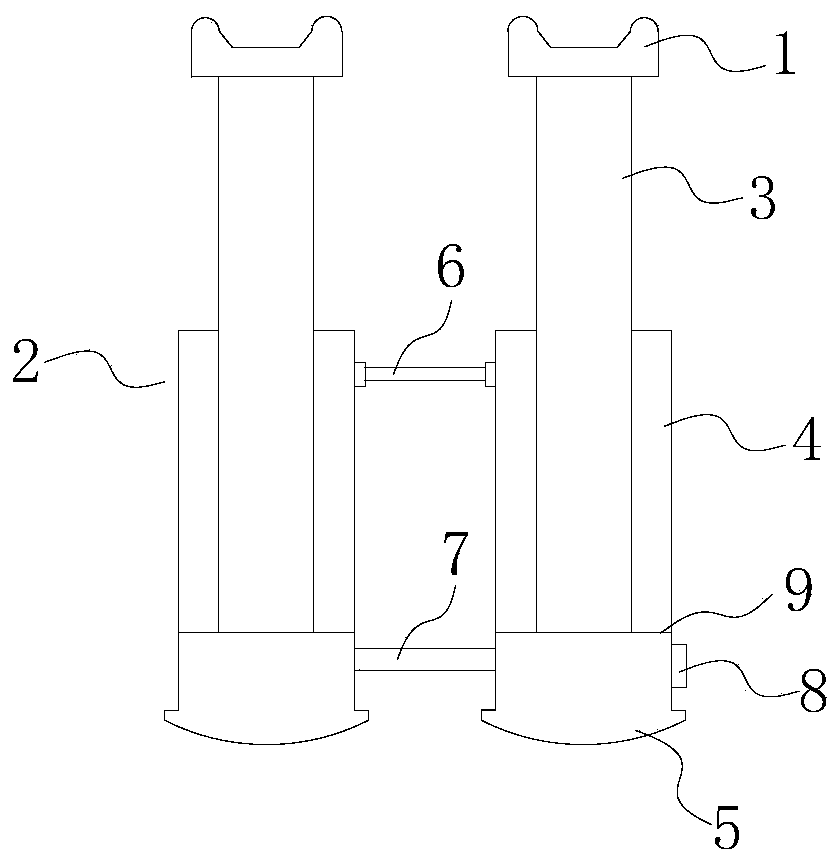

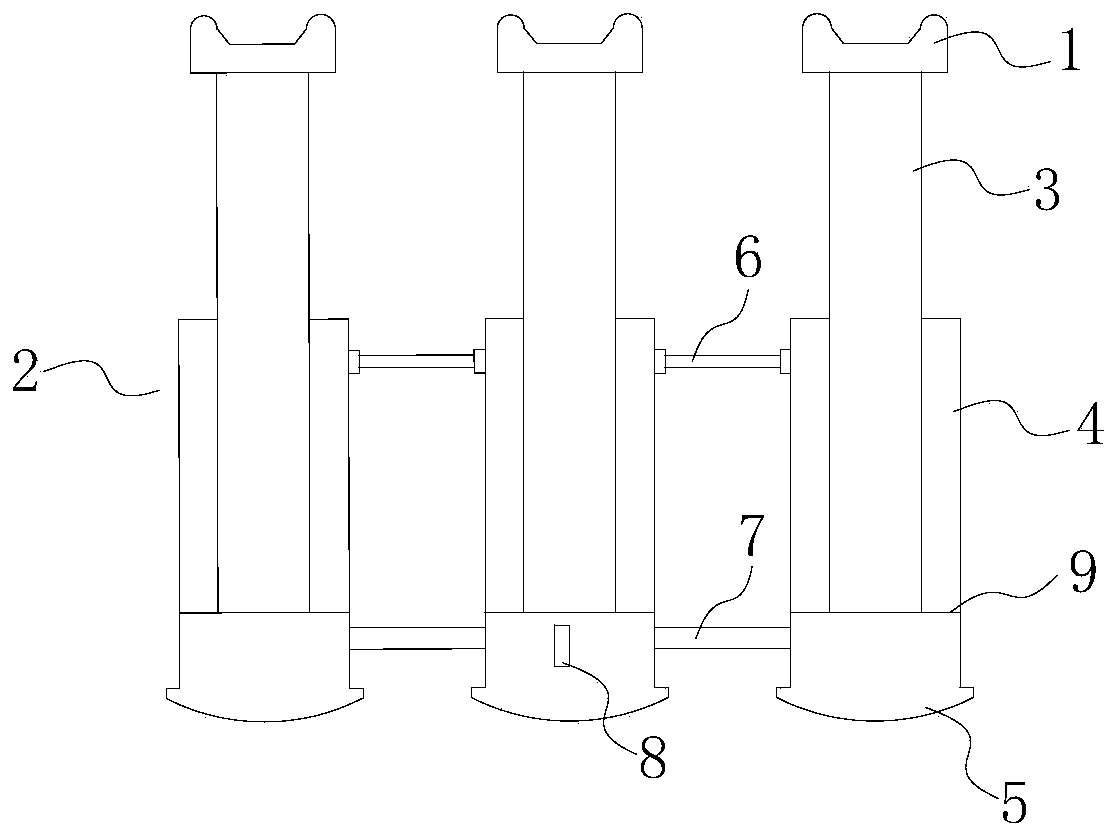

[0033] Step 1. Make and assemble the high-water filling pillar. The pillar includes a pillar body 2, a three-purpose valve 8, a connector 7 and a connecting rod 6. The cylinder body 4 of the pillar body is connected through the connector 7. The three-purpose valve 8 is set on the pillar body Above, the connecting rod 6 connects the adjacent pillar body 2; the pillar can be made in advance according to the environmental conditions of use to adapt to the size of the environmental space.

[0034] Step 2. Make high-water materials. The high-water materials include material A and material B with a weight ratio of 1:1. Material A includes sulphoaluminate cement clinker, suspending agent and super retarder, and material B includes lime and gypsum , suspending agent and compound quick-setting early strength agent.

[0035] Among them, the high-water material, that is, the high...

Embodiment 2

[0042] In order to better exert the support effect of the high-water-filled pillar, this embodiment further improves the high-water material, the structure of the connecting rod and the size of the pillar.

[0043] For high-water materials, according to the test surface in the mining area, the material is composed of two components: material A and material B; material A and material B are used together at a weight ratio of 1:1, and material A is made of sulphoaluminate cement Clinker is the base material, which is mixed with suspending agent and a small amount of super retarder. Sulphoaluminate cement clinker is a glue structure material. Additives for prolonging the setting time, the amount to be added is determined according to actual needs; material B is made by mixing and grinding lime, gypsum, suspending agent and composite quick-setting early strength agent. For example, the weight ratio of each component in material A is 80% to 95% of sulphoaluminate cement clinker, and...

Embodiment 3

[0047] A gob-side entry retaining support method utilizing high-water filling pillars, combined with the above-mentioned support method for high-water filling pillars, such as Figure 5 As shown, the steps include:

[0048] Step a. Support the roadway of the gob-side entry retention. With the mining of the working face, arrange high-water filling pillars on the side of the entry retention, and clean the floating coal on the floor in the space to be supported until the bottom is flat and straight. For leveling.

[0049] Step b. Arrange high-water filling pillars behind the hydraulic supports on the working face. The arrangement direction of the high-water filling pillars is perpendicular to the arrangement direction of the hydraulic supports on the working face. Due to the side of the gob-side retaining, the pressure on the side close to the goaf is relatively high , using more than two pillars side by side, the synchronous lifting of the pillars ensures the stability of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com