Inclined shaft sand prevention oil well pump

An oil well pump and sand control technology, which is applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve problems such as side leakage, ball valve closing lag, and valve balls that cannot be seated in the center, so as to reduce sand jams and improve reliability , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

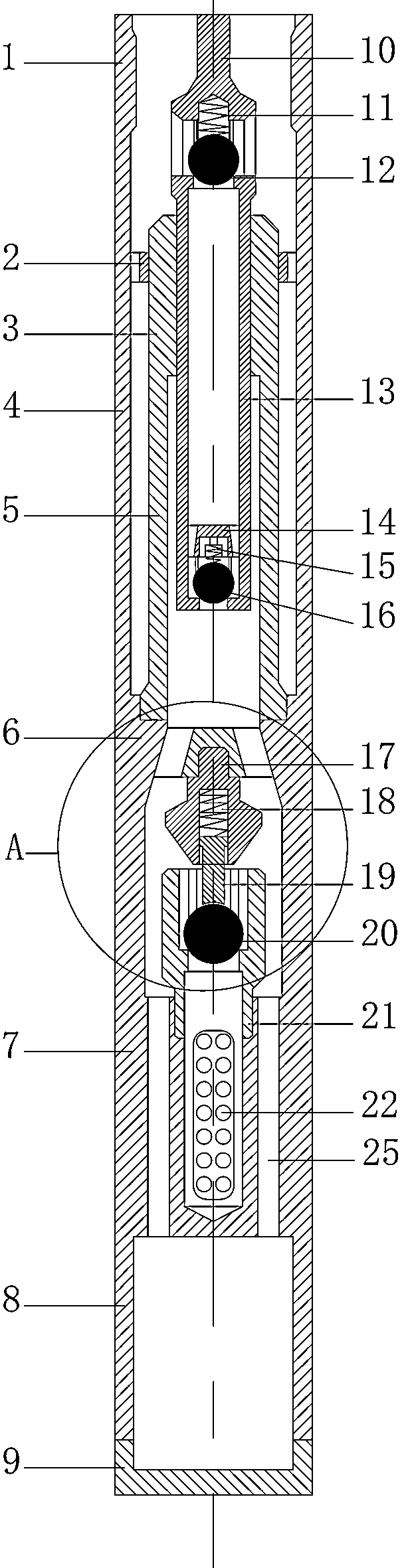

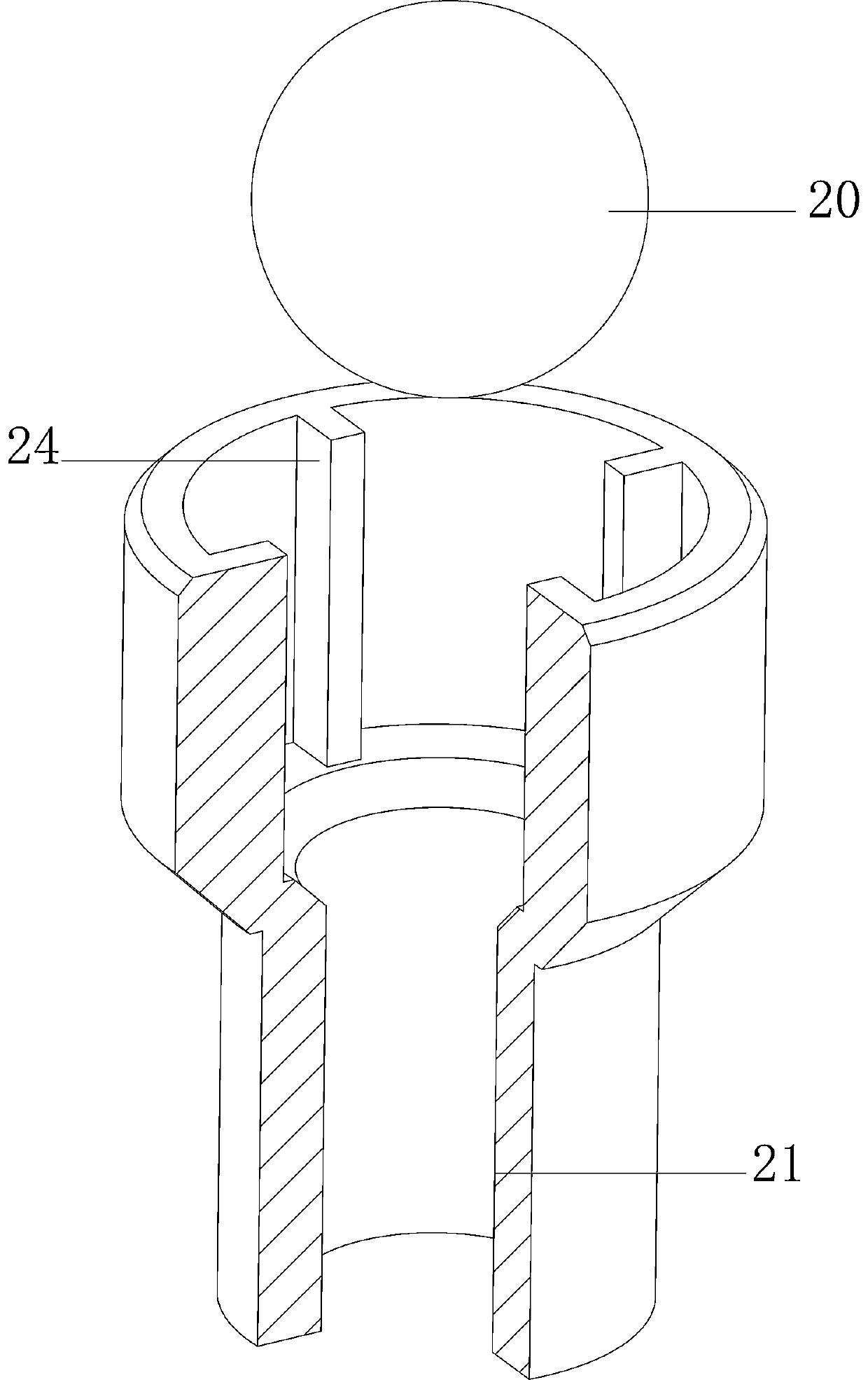

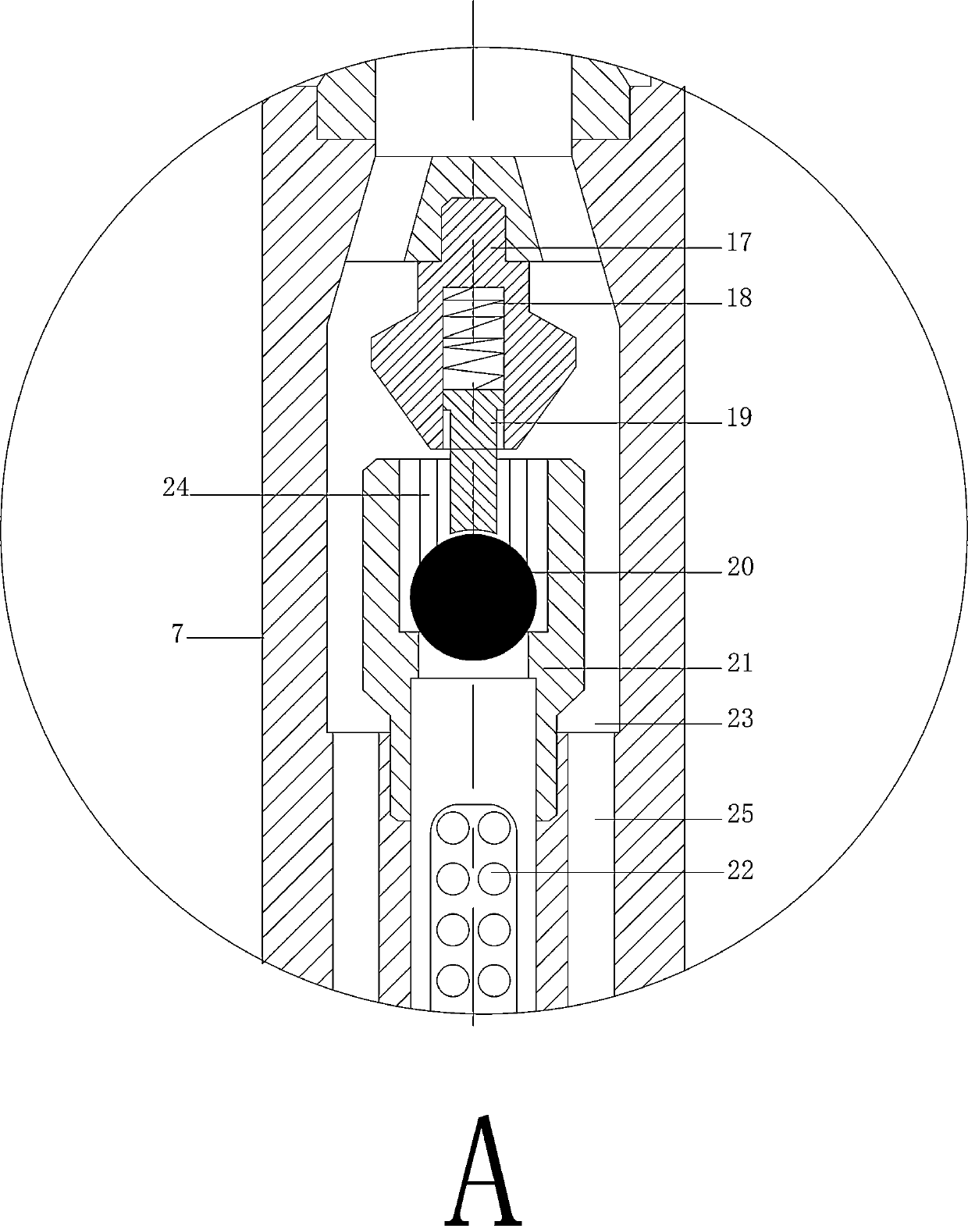

[0031] like Figure 1~3 As shown, an inclined well sand control oil well pump includes a plunger assembly and a pump barrel assembly. The pump barrel assembly includes a bridge pipe 4, an intermediate collar 6 and a double-way joint 7. There is a pump The barrel extension barrel 5 forms a sandy annulus between the pump barrel extension barrel 5 and the bridge pipe 4. The pump barrel extension barrel 5 is provided with a short pump barrel 3 at the upper end, and the short pump barrel 3 is connected to the long plunger 13 in a sliding and sealed manner. . From this structure, such as figure 1 As shown, when the sand in the upper oil pipe of the oil well pump falls on the upper oil outlet valve cover 10, it will slide down along the upper conical surface of the upper oil outlet valve cover 10 into the annular grit chambers on both sides, instead of directly falling into the In the upper outlet valve cover 10 or in the mating surface between the pump cylinder and the long plunge...

Embodiment 2

[0043] Further illustrate in conjunction with embodiment 1, as Figure 1~3 As shown, the pump barrel assembly consists of an upper collar 1, a support ring 2, a short pump barrel 3, a bridge pipe 4, a pump barrel extension barrel 5, an intermediate collar 6, a double-way joint 7, a sanding tailpipe 8, a plug Head 9, stop block 17, the 3rd spring 18, stop pin 19, oil inlet valve ball 20, oil inlet valve cover 21 form.

[0044] The plunger assembly consists of an upper oil outlet valve cover 10, a first spring 11, an upper oil outlet valve ball 12, a long plunger 13, a lower oil outlet valve cover 14, a second spring 15, and a lower oil outlet valve ball 16

[0045] When going into the well, first connect the upper end of the pump barrel assembly with the coupling 1 to the tubing, and run it into the oil well at the designed position along with the tubing string, and then connect the upper end of the plunger assembly to the sucker rod, and with the sucker rod string Go down int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com