Gear vibration mode detection system and detection method

A detection system and detection method technology, which are used in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., to achieve the effects of fast response speed, high measurement accuracy and long transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

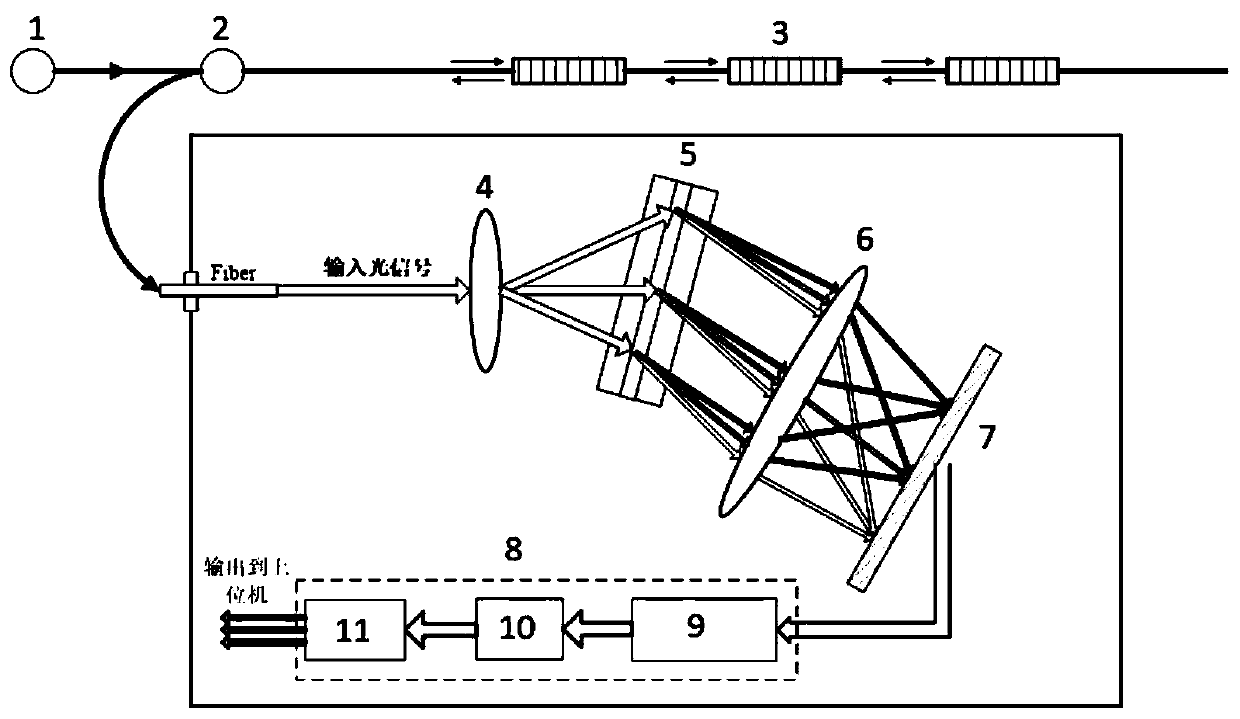

[0024] This embodiment proposes a gear vibration detection system based on fiber grating strain detection, which consists of figure 1 As shown, it mainly includes an ASE broadband light source 1 , a fiber optic circulator 2 , a fiber Bragg grating strain sensor 3 , a photoelectric detection unit and an electrical processing unit 8 . Among them, the ASE broadband light source 1 is connected with the A end of the optical fiber circulator 2, the B end of the optical fiber circulator 2 is connected with the fiber grating strain sensor 3; the C end of the optical fiber circulator 2 is connected with the photoelectric detection unit, and the photoelectric detection unit is connected with the electric The processing unit 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com