Cigarette capable of preventing substances in fuming medium from leaking and diffusing and preparation method of cigarette

A cigarette and material technology, applied in tobacco, food science, cigar manufacturing, etc., can solve the problems of material leakage, diffusion, heating cigarettes without anti-penetration effect, etc., and achieve sufficient release and heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

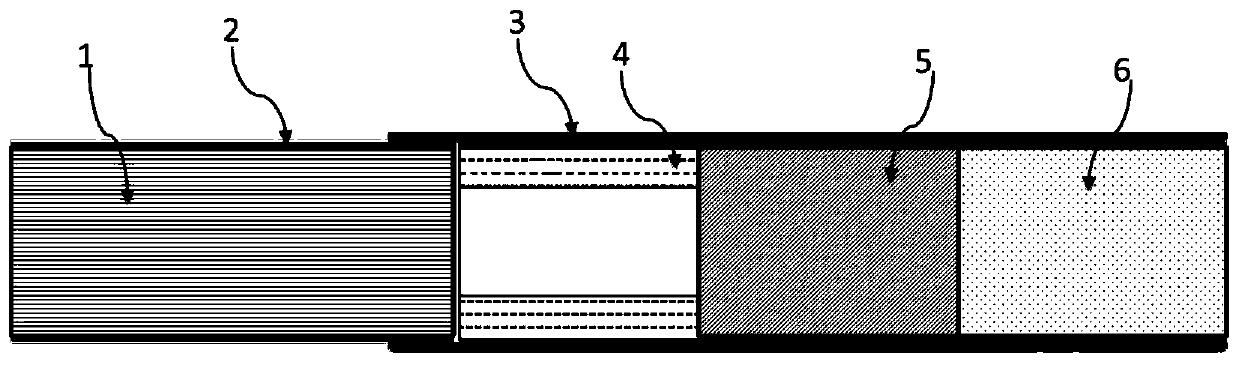

[0033] This embodiment 1 is a cigarette that prevents substances in the smoking medium from seeping out and diffusing to the surface of the cigarette. The cigarette includes a smoking medium rod 1 and a composite cigarette paper 2;

[0034] Wherein, the outer side of the smoking medium rod 1 is wrapped with the composite cigarette paper 2;

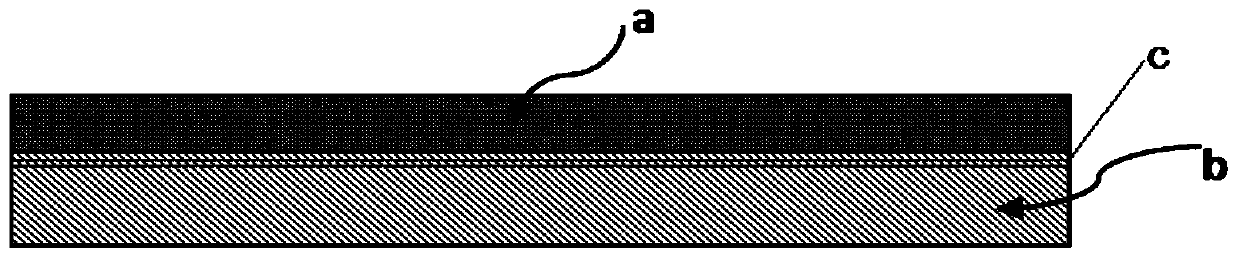

[0035] The composite cigarette paper 2 is composed of a metal layer a, an oil-repellent and hydrophobic layer b, and an adhesive layer c between the two layers. The metal layer a is in contact with the smoking medium rod 1 .

[0036] The metal layer a is an aluminum foil layer.

[0037] The preparation method of above-mentioned cigarette, comprises the following steps:

[0038] A, in the sizing process in the cigarette paper preparation process, add the oil repellent styrene acrylic resin of 0.8% of pulp dry weight and the hydrophobic agent AKD (alkyl ketene dimer) emulsion of 1% of paper pulp dry weight, obtain The cigarette paper is th...

Embodiment 2

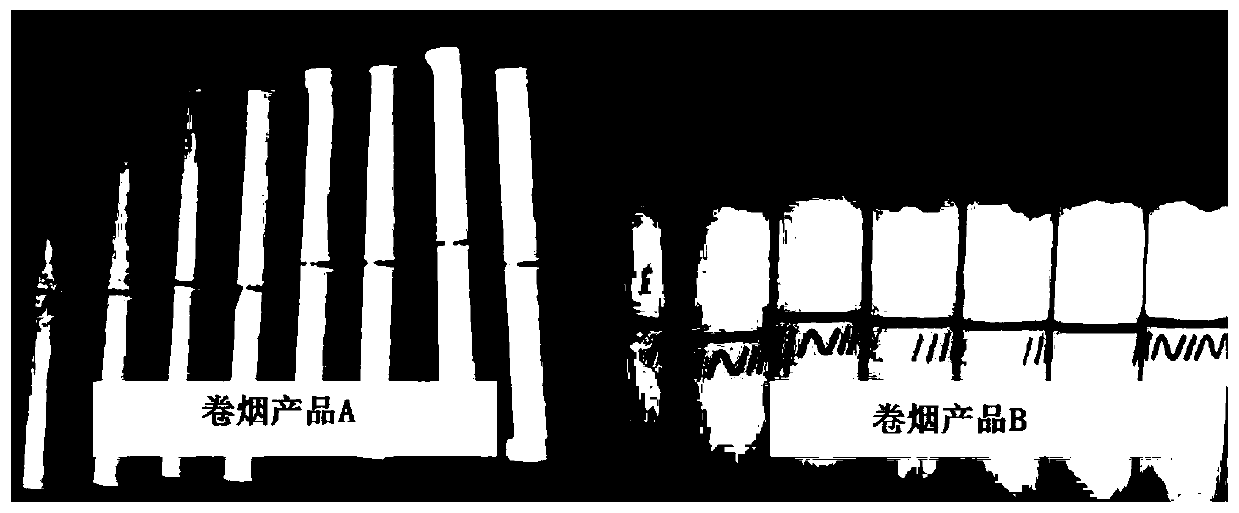

[0045] Two types of cigarette products A and B were prepared respectively by conventional process operations, and liquid spices were added to the tobacco medium. The only difference was that cigarette product A wrapped the smoking medium rod 1 with the composite cigarette paper 2 described in Example 1, and the cigarette product A B wraps the smoking medium rod 1 with ordinary cigarette paper. Put the two types of cigarette products A and B in an environment with a temperature of 40°C and a humidity of 62%. After 24 hours, observe the spices and moisture in the smoking medium rod Penetration and diffusion on cigarettes, the surface of cigarette products such as image 3 shown.

[0046] image 3 It shows that the surface of cigarette product A is clean without any penetration and diffusion phenomenon, and the flavor and moisture of cigarette product B permeate and diffuse seriously at the port of the smoking medium rod. This shows that the composite cigarette paper 2 of the p...

Embodiment 3

[0048] The two types of cigarette products A and B in Example 2 were tested for the total particulate matter in the smoke components and nicotine in the smoke, and the results are shown in Table 1.

[0049]Table 1 shows that: after using the composite cigarette paper 2 of the present invention, both the total particulate matter and the smoke nicotine in the smoke components increase to varying degrees, indicating that the heating of the tobacco core material is more sufficient after the composite cigarette paper is used. Utilization is higher.

[0050] Table 1 Contents of smoke components in cigarette products A and B (average value)

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com