Organic waste gas treatment machine for lining extraction neutralization and oil scraping on basis of ethyl acetate

A technology of ethyl acetate and organic waste gas, which is applied in gas treatment, organic chemistry, carboxylate preparation, etc. It can solve the problems of insufficient neutralization saturation, intensified acid corrosion, corrosion and rust of oxide film and metal shell plate, etc. Achieve the effects of avoiding the penetration of the upper and lower layers, stabilizing the flow rate and adhesion, and improving the quality assurance operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

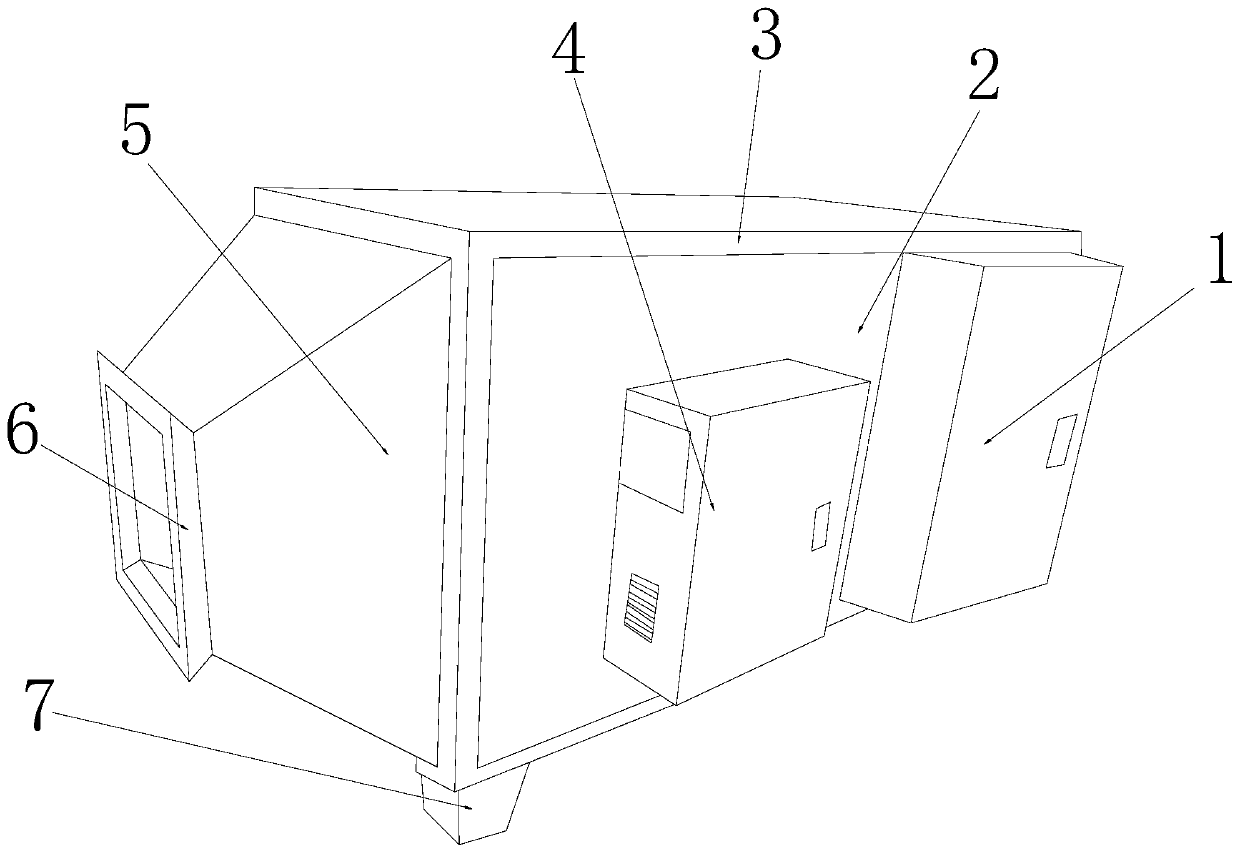

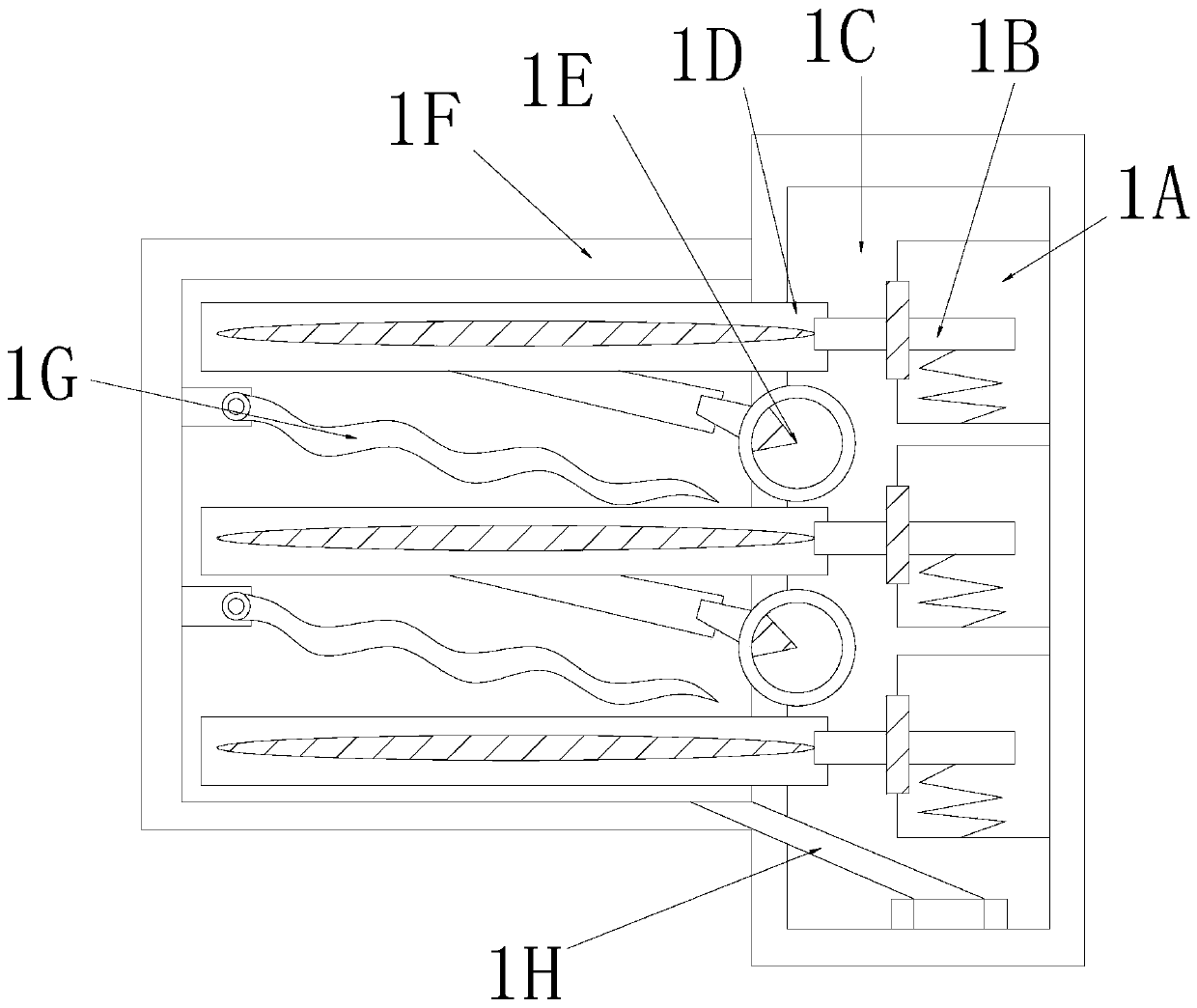

[0034] see Figure 1-Figure 7 , the present invention provides an organic waste gas treatment machine based on ethyl acetate for lining neutralization and scraping. The platform slot cover cap 5, the ventilation pipe interface 6, the supporting column foot block 7, the liner laminated grid slot 1 is nested in the front side of the shell frame slot 3, and the baffle plate 2 is provided with two and inserted respectively On the front and back sides of the shell frame slot 3, the distribution box 4 is close to the front side of the shell frame slot 3, the baffle plate 2 and the distribution box 4 are on the same vertical plane, and the step slot cover The cap 5 is welded together with the ventilation pipe interface 6. The ventilation pipe interface 6 is nested on the left side of the shell frame groove 3 and communicates with each other. Under the four bottom corners of the liner, the liner stacked grid groove 1 is provided with a lifting grid tank box 1A, a shaft wheel lift bar...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides an organic waste gas treatment machine based on ethyl acetate-based pumping lining and scraping ester, other aspects are the same as embodiment 1, the difference is:

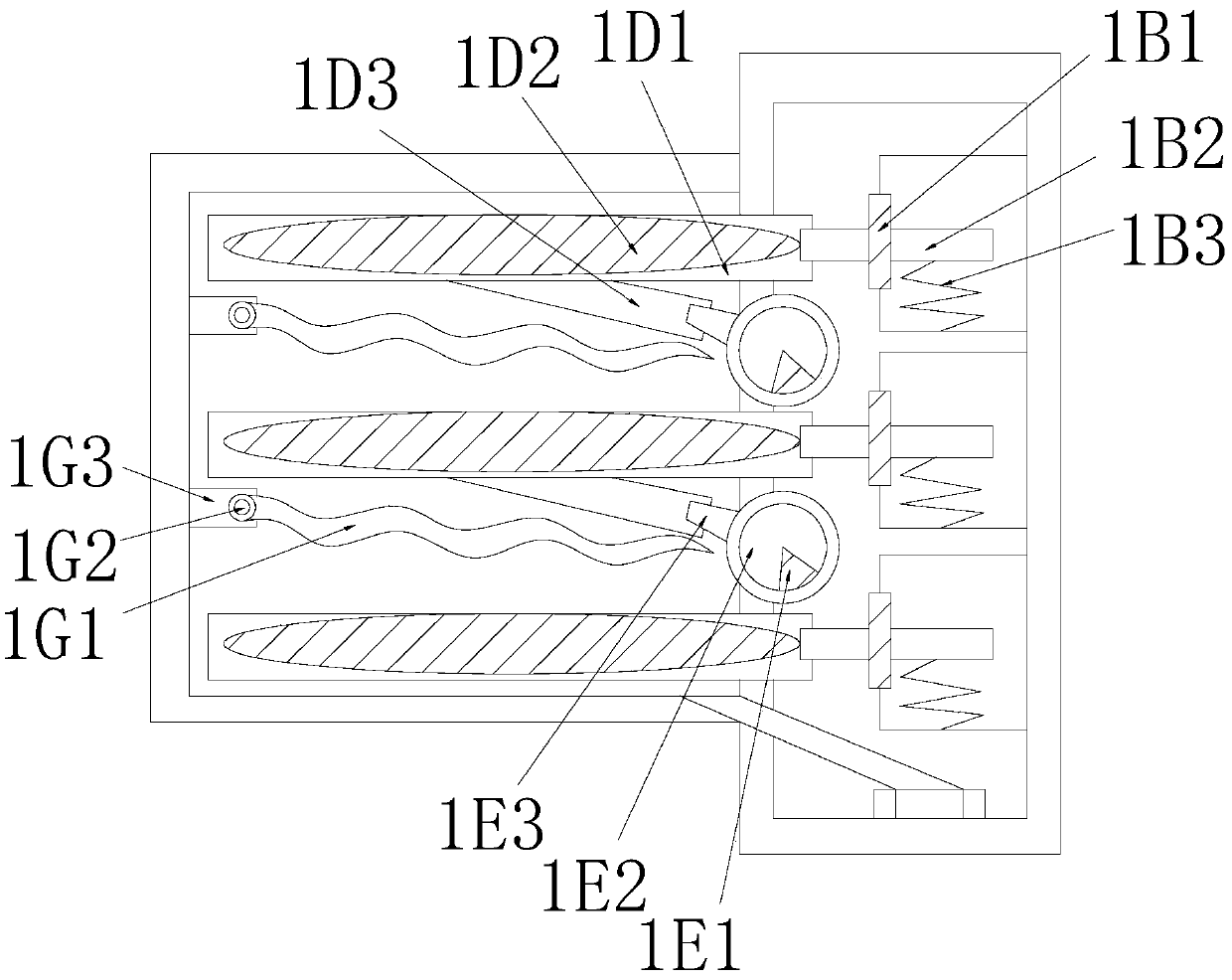

[0042] see image 3 The alkali balloon cylinder tank 1E is composed of a triangular plate 1E1, a ball cylinder tank 1E2, and a convex tube body 1E3. The triangular plate 1E1 is mechanically connected with the ball cylinder tank 1E2 and the axes are collinear. The convex tube body 1E3 is welded on The upper left corner of the ball cylinder groove 1E2 is connected with each other, and the convex pipe body 1E3 is inserted through the ball cylinder groove 1E2 to conduct the pipeline of the bottom lining plate groove to form the operation of quantitatively injecting alkaline gas at the bottom to ensure that the quantitative acid gas with the lining plate is formed to form a uniform bottom Enhance the adhesion effect.

[0043] see Figure 6 The triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com