Treatment method and system for polyphenylene sulfide production synthesis waste gas

A treatment system, polyphenylene sulfide technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as pollution, equipment blockage, exhaust gas not up to standard environment, etc., to reduce environmental pollution and avoid pollution , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

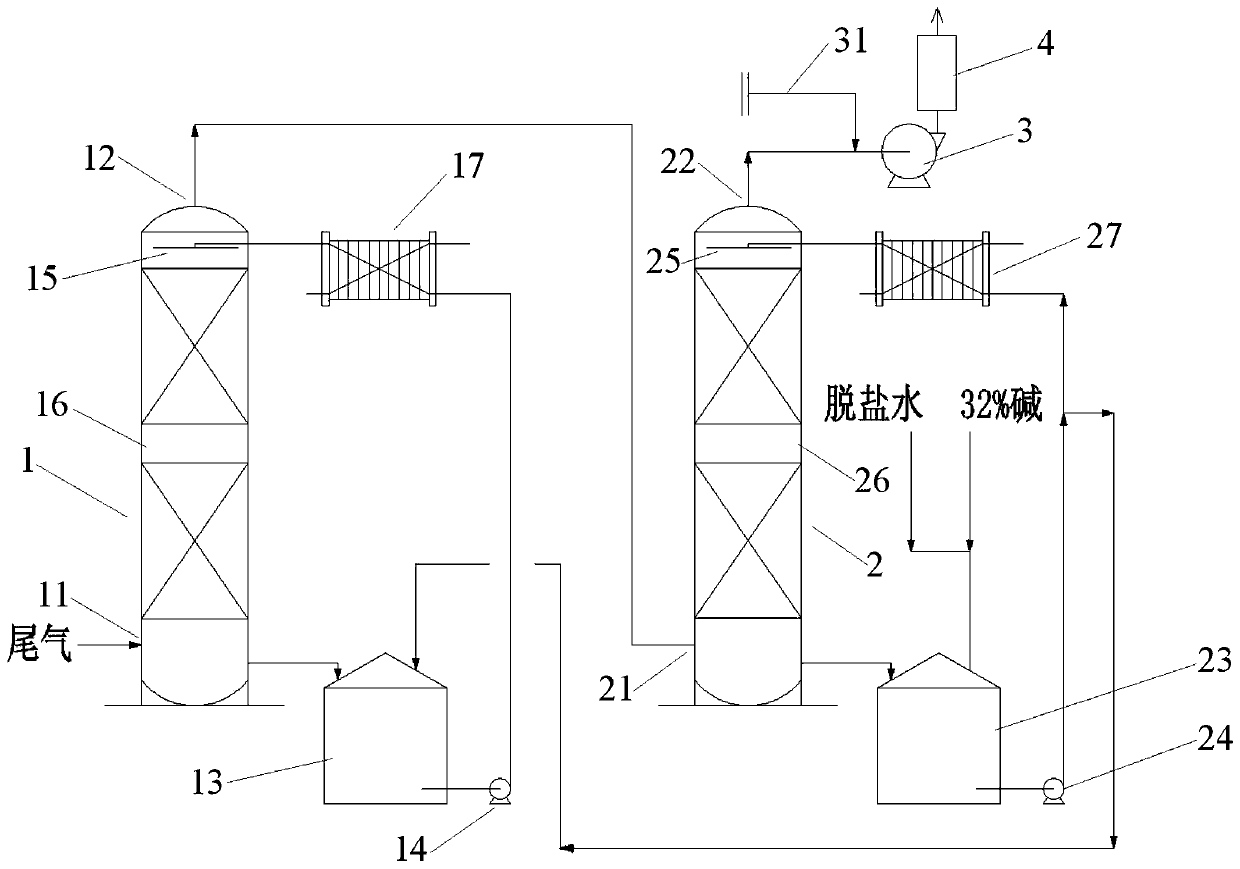

[0032] The tail gas containing hydrogen sulfide produced in the production process of polyphenylene sulfide, that is, the synthetic waste gas of polyphenylene sulfide production, is specifically treated by chemical absorption method in this example, and its main treatment equipment includes series scrubbers and tail gas towers.

[0033] Therefore, the PPS production synthetic waste gas treatment system in this example, such as figure 1 Shown, comprise washing tower 1 and tail gas tower 2 connected in series; The top of washing tower 1 is provided with lye inlet and washing tower waste gas outlet 12, and the bottom of washing tower is provided with alkali liquor outlet and washing tower waste gas inlet 11; Washing tower waste gas The inlet 11 is used to connect the exhaust gas to be treated, and the exhaust gas outlet 12 of the scrubber communicates with the bottom of the tail gas tower through a pipeline. The washing tower 1 is equipped with a circulating alkali tank 13 and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap