Cutting mechanism for garbage disposal crusher

A cutting mechanism and garbage disposal technology, which is applied in the direction of grain processing, etc., can solve problems such as inability to form effective complementarity, average crushing effect, and insufficient processing, and achieve the effect of compact structure, low production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

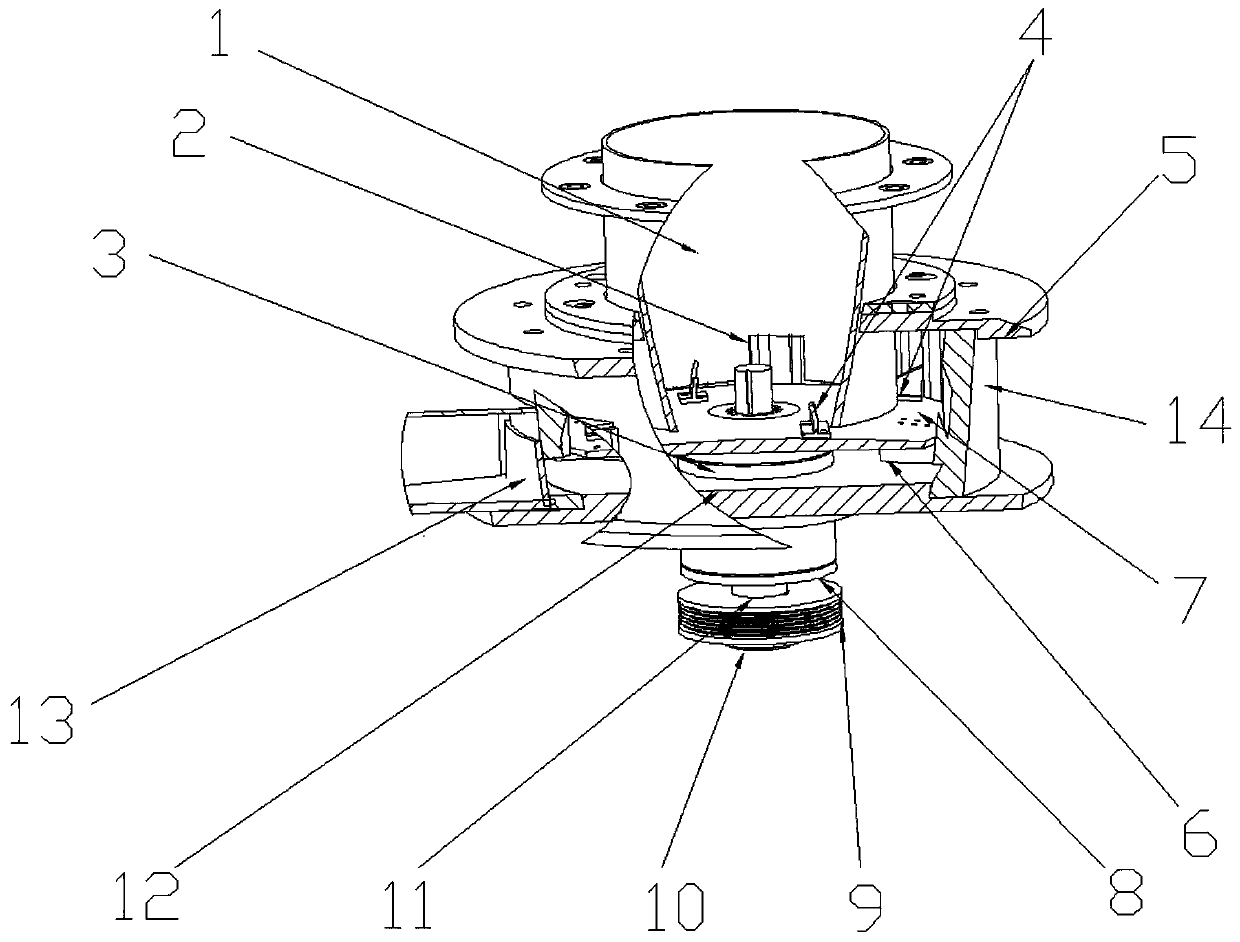

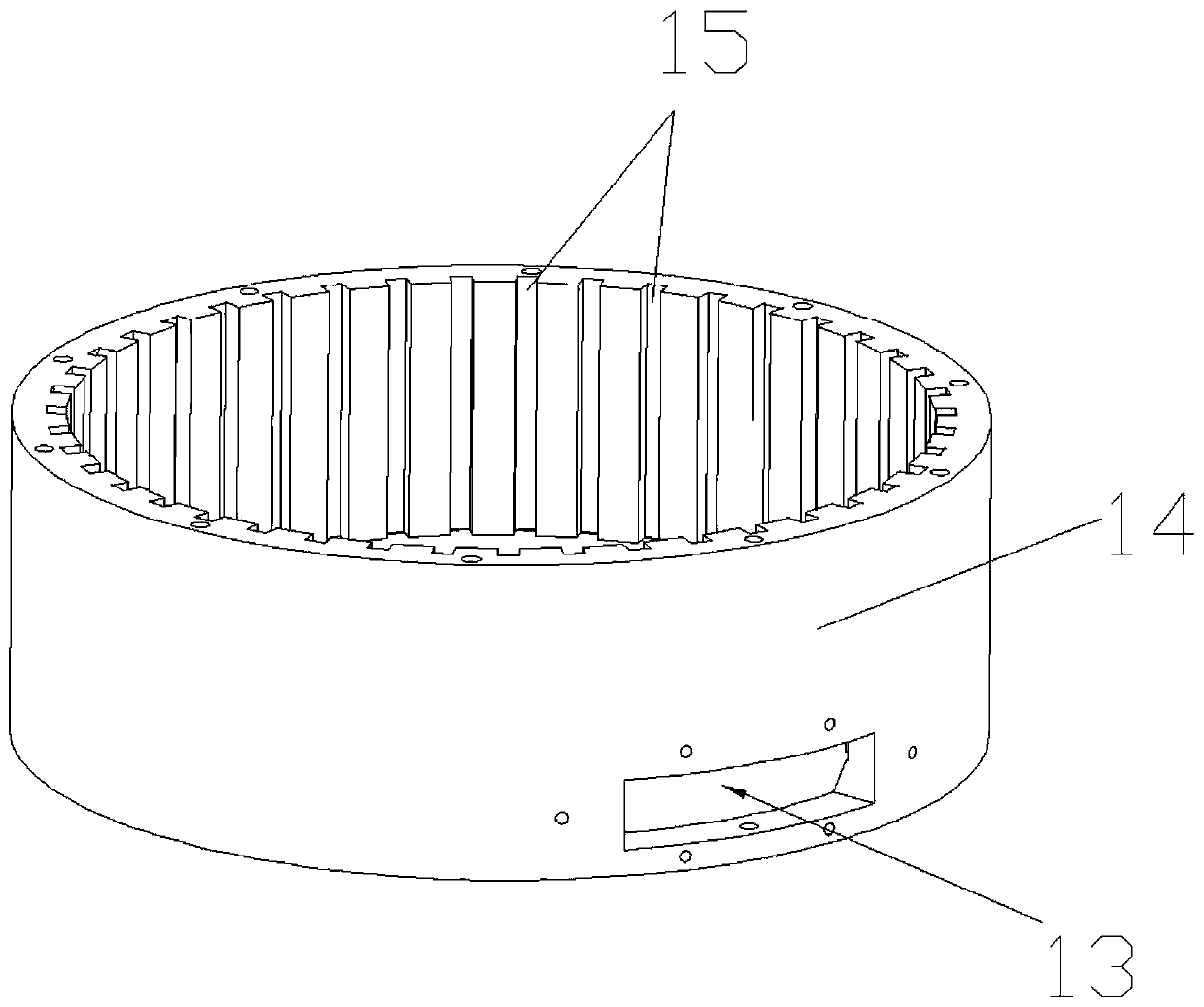

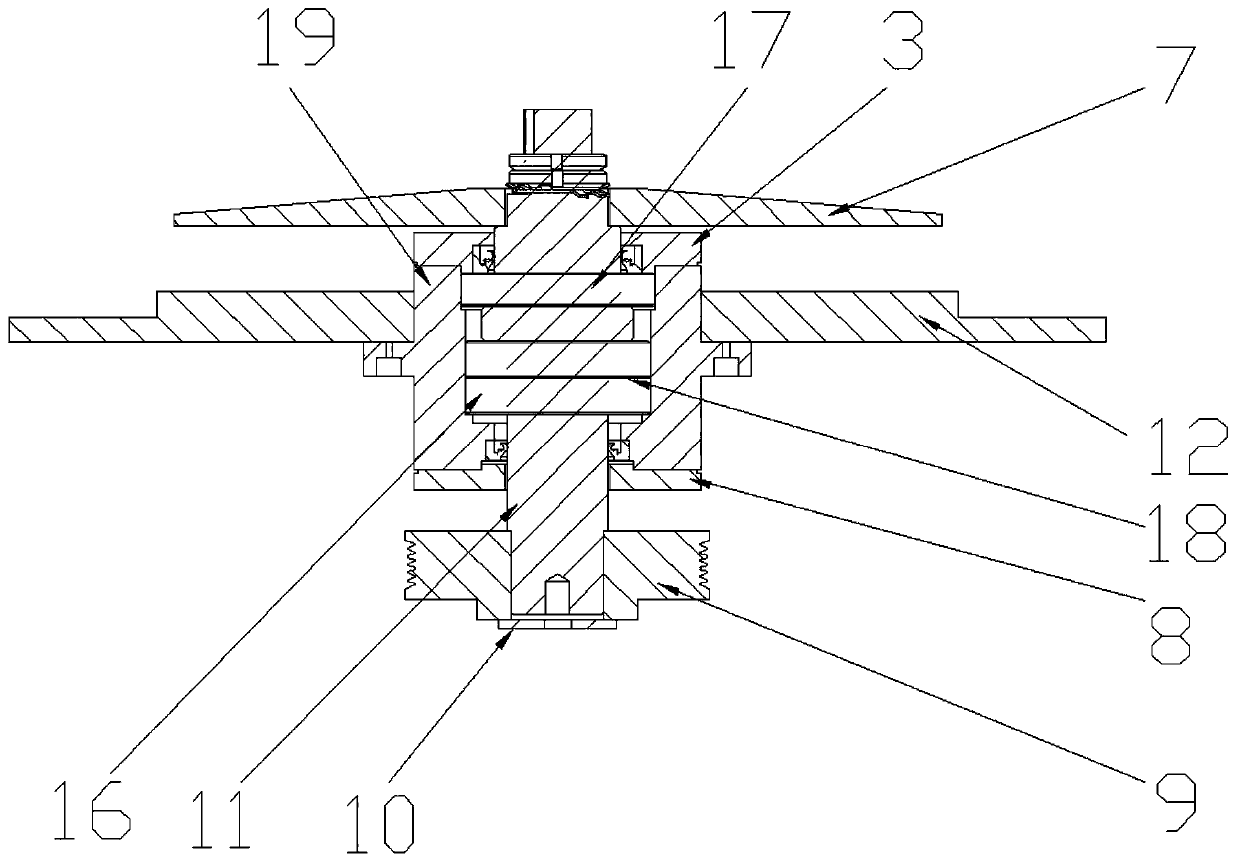

[0016] Such as Figure 1-Figure 3 The shown cutting mechanism of a garbage disposal shredder includes a motor and a rotating shaft structure. The rotating shaft structure passes through the flange chassis 12 to connect to the cutter head. A barrel 1 is arranged above the cutter head 7. Set outwards from the center two groups of pulverizing knives 4 that are circumferentially distributed inside and outside. There is a material inlet 2 on one side of the lower part, and a gear cutter head 14 is arranged outside the cutter head, and the gear cutter head 14 is located between the top cover flange 5 and the flange chassis 12 . A discharge opening 13 is arranged on one side of the lower part of the gear cutter head.

[0017] A gap is formed between the gear cutter head and the cutter head, and a circle of vertical tooth grooves 15 is formed on the inner wall of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap