Welding operation method for transition layer and composite layer of composite steel plate

A composite steel plate and operation method technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of increasing the difficulty of welding construction operations, waste of corrosion-resistant alloy materials, and increasing welding workload, etc., to achieve The effect of improving the utilization rate of welding rods, improving work efficiency and reducing the difficulty of welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

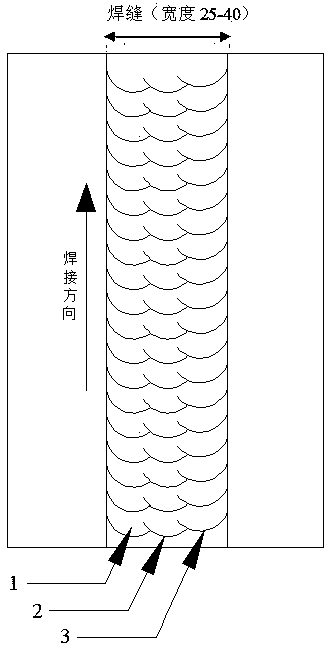

Method used

Image

Examples

Embodiment 1

[0038] The material of an engineering equipment in the company is 15CrMoR+0Cr13 composite steel plate, the thickness is (16+3) mm; the nickel-based electrode Ni337 is used, the diameter is ¢3.2, and it is welded by the traditional method. Due to the difficulty in the operation of the electrode and the difficulty in controlling the shape of the weld, there has been a Transition layer crack defects.

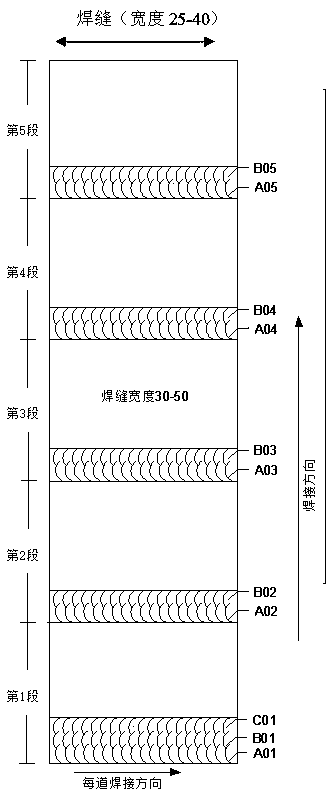

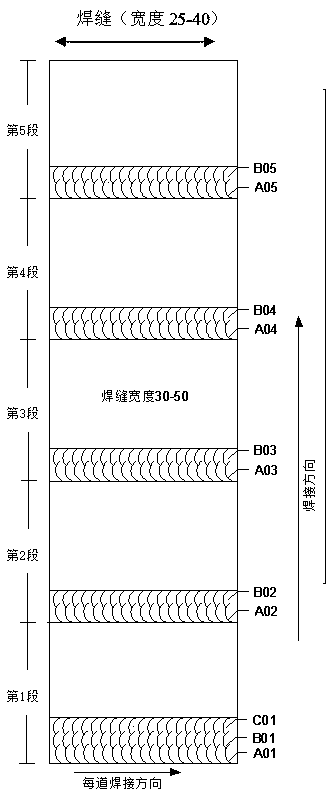

[0039] Adopt technical scheme of the present invention, step is as follows:

[0040] (1) Groove type: adopt V-shaped groove on the base side, and the peeling width of each side of the compound layer is 15mm;

[0041] (2) The transition layer is welded by the segmented horizontal welding operation method: the width of the stripped weld is 33mm;

[0042] (3) Divide the weld seam into several sections with a length of about 180mm, start welding one piece at the lower part of the first section using the horizontal welding operation method, and start welding one piece at the lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com