A method for microbial in-situ inhibition of hydrogen sulfide release from comprehensive tannery sludge

A technology of microorganisms and hydrogen sulfide, which is applied in the methods of using microorganisms, biochemical equipment and methods, biological sludge treatment, etc. The effect of suppressing the release of hydrogen sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

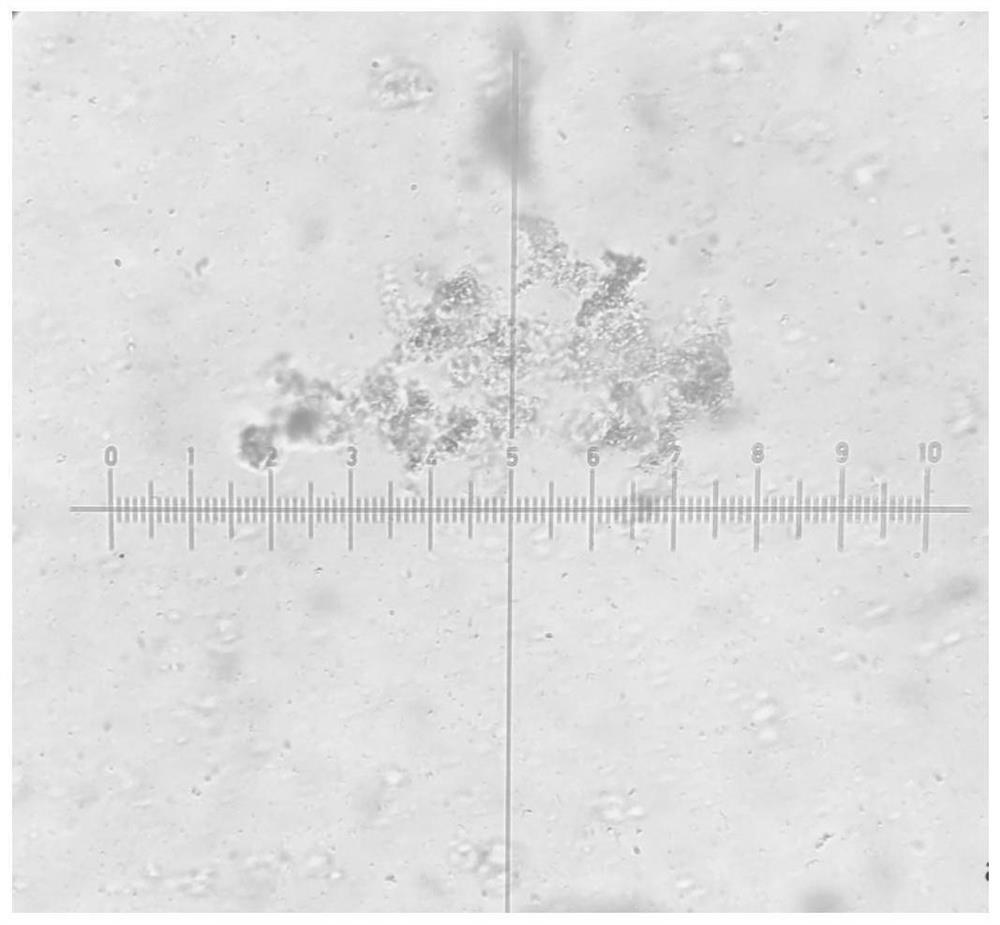

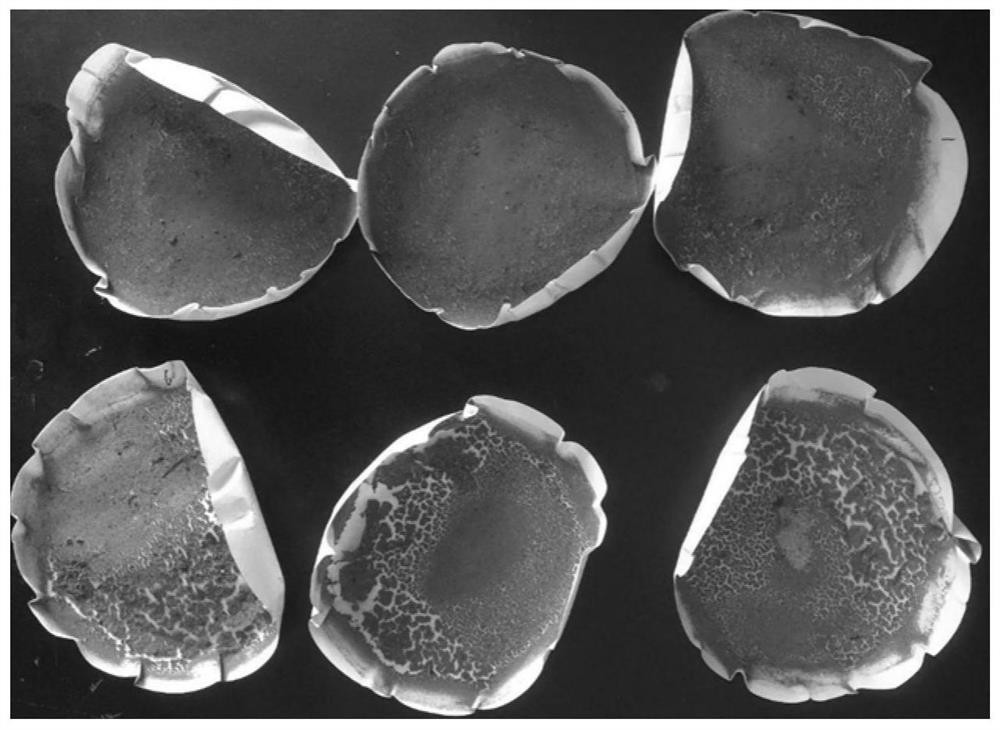

Image

Examples

Embodiment 1

[0045] Step 1, preparation of functional microbial flora

[0046] ①Take 0.1L of sludge from a tannery sludge thickening tank in a tannery, and add nutrients to it, which include beef extract and peptone; among them, beef extract is added at a concentration of 2g / L, and peptone is added at a concentration of 4g / L The amount of L was added; culture was shaken at a constant temperature at 30° C. and 100 rpm for 24 hours to obtain a microorganism-enriched culture.

[0047] ② The microbial enrichment culture was inoculated into the sterilized screening medium according to the inoculation amount of 10%, and cultured at a constant temperature and shaking at 30°C and 80rpm for 11 days, and the medium became turbid.

[0048] Wherein, the screening medium is prepared according to the following method: the sludge in the tannery sludge concentration tank is thermally hydrolyzed at 150°C for 10 minutes, then filtered with filter paper, the filtrate is collected, and KH 2 PO 4 2.0g / L, NH ...

Embodiment 2

[0054] Step 1, preparation of functional microbial flora

[0055] ①Take 0.1L of sludge from a tannery sludge thickening tank in a tannery, and add nutrients to it. The nutrients include beef extract and peptone; among them, beef extract is added at a concentration of 5g / L, and peptone is added at a concentration of 10g / L The amount of L was added; culture was shaken at a constant temperature at 25° C. and 60 rpm for 20 hours to obtain a microorganism-enriched culture.

[0056] ② The microbial enrichment culture was inoculated into the sterilized screening medium according to the inoculum amount of 10%, and cultured at a constant temperature and shaking at 30°C and 60rpm for 8 days, and the medium became turbid.

[0057] Wherein, the screening medium is prepared according to the following method: the sludge in the tannery sludge concentration tank is thermally hydrolyzed at 110°C for 15 minutes, then filtered with filter paper, the filtrate is collected, and KH 2 PO 4 2.0g / L...

Embodiment 3

[0063] Step 1, preparation of functional microbial flora

[0064] ①Take 0.1L of sludge from a tannery sludge concentration tank in a tannery, and add nutrients to it, which include beef extract and peptone; among them, beef extract is added at a concentration of 3.5g / L, and peptone is added at a concentration of 7g The amount of / L was added; culture was shaken at a constant temperature at 30°C and 100 rpm for 12 hours to obtain a microorganism-enriched culture.

[0065] ② The microbial enrichment culture was inoculated into the sterilized screening medium according to the inoculum amount of 10%, and cultivated at 30°C and 80rpm for 5 days with constant temperature shaking, and the medium became turbid.

[0066] Wherein, the screening medium is prepared according to the following method: the sludge in the tannery sludge concentration tank is thermally hydrolyzed at 120°C for 10 minutes, then filtered with filter paper, the filtrate is collected, and KH 2 PO 4 2.0g / L, NH 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com