Special composite anti-cracking agent for ultra-high performance concrete

An ultra-high performance, anti-cracking agent technology, applied in the field of building materials, can solve the problems of low water-to-binder ratio, high cracking risk, and large amount of cementitious materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

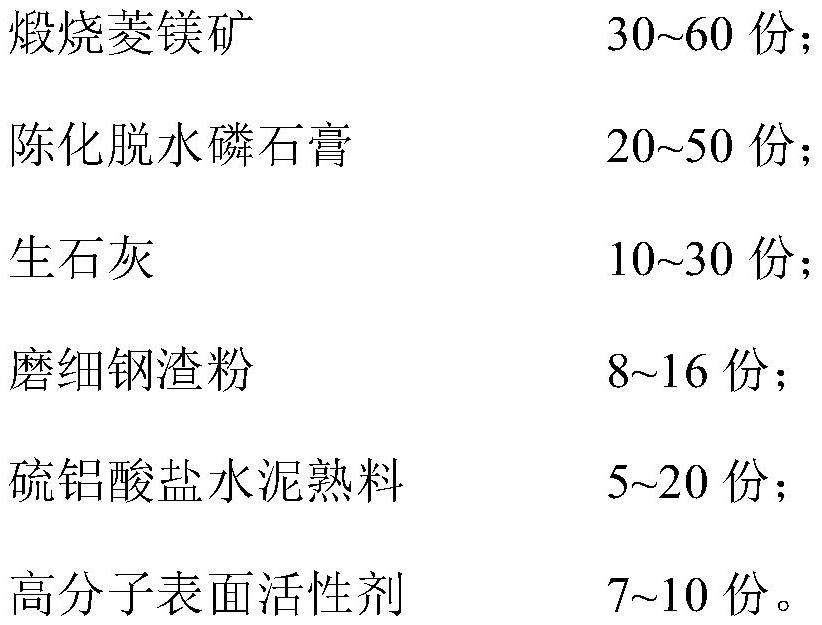

Method used

Image

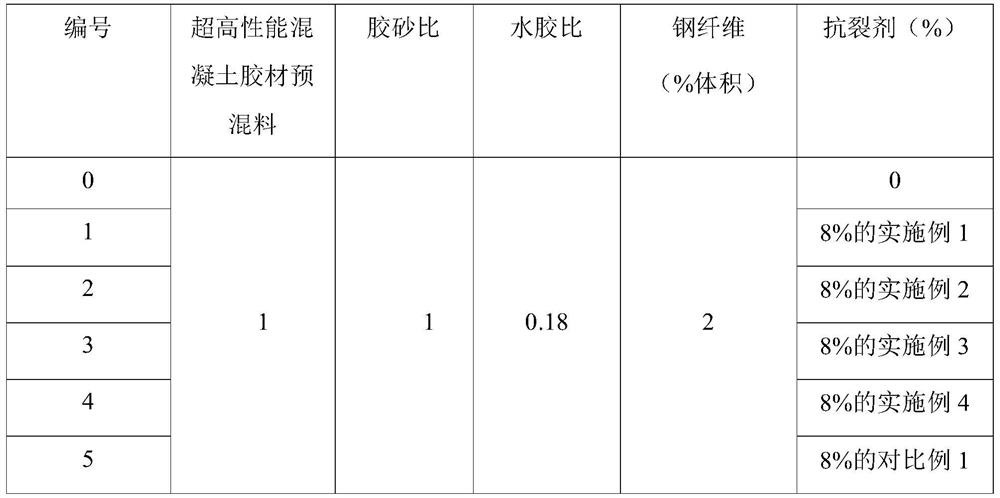

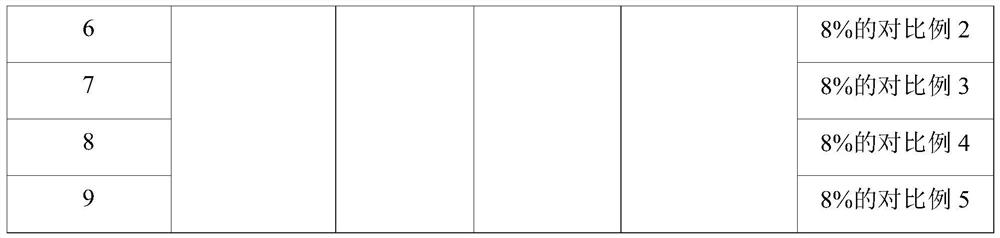

Examples

Embodiment 1

[0025] Composite anti-cracking agent for ultra-high performance concrete, composed of the following components by weight: 40 parts of calcined magnesite; 25 parts of aged dehydrated phosphogypsum; 16 parts of quicklime; 8 parts of finely ground steel slag powder; sulfoaluminate 17 parts of cement clinker; 8 parts of polymer surfactant.

[0026] The calcined magnesite is magnesite crushed to a particle size of 10 cm. After being calcined and kept at 700° C. and 1100° C. for 3 hours, the calcined magnesite was mixed and ground at a mass ratio of 3:1 to an average particle size of 80 μm.

[0027] The phosphogypsum is a by-product in the process of wet-process phosphoric acid production. After being discharged, landfilled, and aged for more than 1 year, it is dried at 110°C for 4 hours until it is completely dehydrated, and finally ground into powder to obtain aged and dehydrated Phosphogypsum powder.

[0028] The quicklime is calcareous lime in accordance with JC / T 621, and meet...

Embodiment 2

[0035] Composite anti-cracking agent for ultra-high performance concrete, composed of the following components by weight fraction: 45 parts of calcined magnesite; 25 parts of aged dehydrated phosphogypsum; 11 parts of quicklime; 8 parts of finely ground steel slag powder; sulfoaluminate 17 parts of cement clinker; 8 parts of polymer surfactant.

[0036] The calcined magnesite is magnesite crushed to a particle size of 10 cm. After being calcined and kept at 700° C. and 1100° C. for 3 hours, the calcined magnesite was mixed and ground at a mass ratio of 3:1 to an average particle size of 80 μm.

[0037] The phosphogypsum is a by-product in the process of wet-process phosphoric acid production. After being discharged, landfilled, and aged for more than 1 year, it is dried at 110°C for 4 hours until it is completely dehydrated, and finally ground into powder to obtain aged and dehydrated Phosphogypsum powder.

[0038] The quicklime is calcareous lime in accordance with JC / T 621,...

Embodiment 3

[0045] Composite anti-cracking agent for ultra-high performance concrete, composed of the following components by weight: 50 parts of calcined magnesite; 20 parts of aged dehydrated phosphogypsum; 16 parts of quicklime; 8 parts of finely ground steel slag powder; sulfoaluminate 12 parts of cement clinker; 8 parts of polymer surfactant.

[0046] The calcined magnesite is magnesite crushed to a particle size of 10 cm. After being calcined and kept at 700° C. and 1100° C. for 3 hours, the calcined magnesite was mixed and ground at a mass ratio of 3:1 to an average particle size of 80 μm.

[0047] The phosphogypsum is a by-product in the process of wet-process phosphoric acid production. After being discharged, landfilled, and aged for more than 1 year, it is dried at 110°C for 4 hours until it is completely dehydrated, and finally ground into powder to obtain aged and dehydrated Phosphogypsum powder.

[0048] The quicklime is calcareous lime in accordance with JC / T 621, and meet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com