Latex emulsion adhesive with stable mechanical properties, and preparation method thereof

An adhesive and emulsion technology, applied in the direction of adhesives, natural rubber adhesives, polymer adhesive additives, etc., can solve the problems of unstable mechanical properties and effects, and achieve the advantages of improving mechanical properties, improving stability and enhancing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

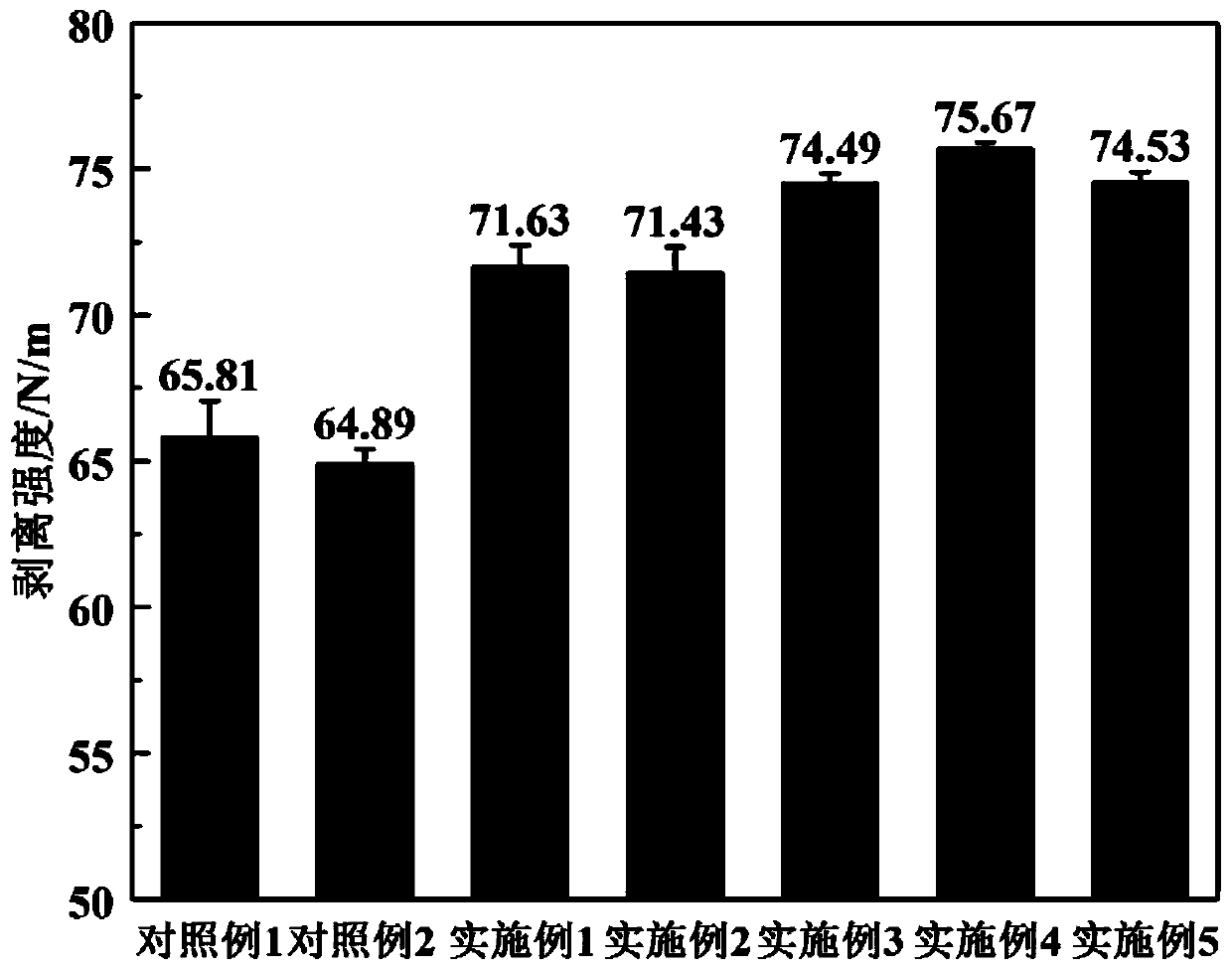

Embodiment 1

[0027] 100 g of natural latex and 1.0 g of regenerated silk fibroin solution were placed in a stirred tank at 40° C. and stirred at a constant temperature for 30 minutes to prepare a natural latex-regenerated silk fibroin mixed emulsion. Put 5.0g of white oil and 0.5g of emulsifying thickener C-580 into a beaker, stir at 40°C for 5 minutes, then pour it into a stirring tank, continue to stir for 5 minutes, add 4.0g of water-based tackifying resin XY- 8025, stirred for 5 minutes, then added 0.15g of defoamer B-422, stirred for 5 minutes, after the stirring was completed, filtered, and the finished adhesive was obtained.

Embodiment 2

[0029] 100 g of natural latex and 2.0 g of regenerated silk fibroin solution were placed in a stirred tank at 40° C. and stirred at a constant temperature for 30 minutes to prepare a natural latex-regenerated silk fibroin mixed emulsion. Put 5.0g of white oil and 0.5g of emulsifying thickener C-580 into a beaker, stir at 40°C for 5 minutes, then pour it into a stirring tank, continue to stir for 5 minutes, add 4.0g of water-based tackifying resin XY- 8025, stirred for 5 minutes, then added 0.15g of defoamer B-422, stirred for 5 minutes, after the stirring was completed, filtered, and the finished adhesive was obtained.

Embodiment 3

[0031] 100 g of natural latex and 3.0 g of regenerated silk fibroin solution were placed in a stirred tank at 40° C. and stirred at a constant temperature for 30 minutes to prepare a natural latex-regenerated silk fibroin mixed emulsion. Put 5.0g of white oil and 0.5g of emulsifying thickener C-580 into a beaker, stir at 40°C for 5 minutes, then pour it into a stirring tank, continue to stir for 5 minutes, add 4.0g of water-based tackifying resin XY- 8025, stirred for 5 minutes, then added 0.15g of defoamer B-422, stirred for 5 minutes, after the stirring was completed, filtered, and the finished adhesive was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com