Preparation method of sports knitted fabric

A knitted fabric and sports technology, applied in the field of fibers, can solve the problem that the efficiency of moisture conduction needs to be further improved, and achieve the effects of excellent antibacterial properties, excellent moisture absorption and quick drying, and improving the ability to export moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

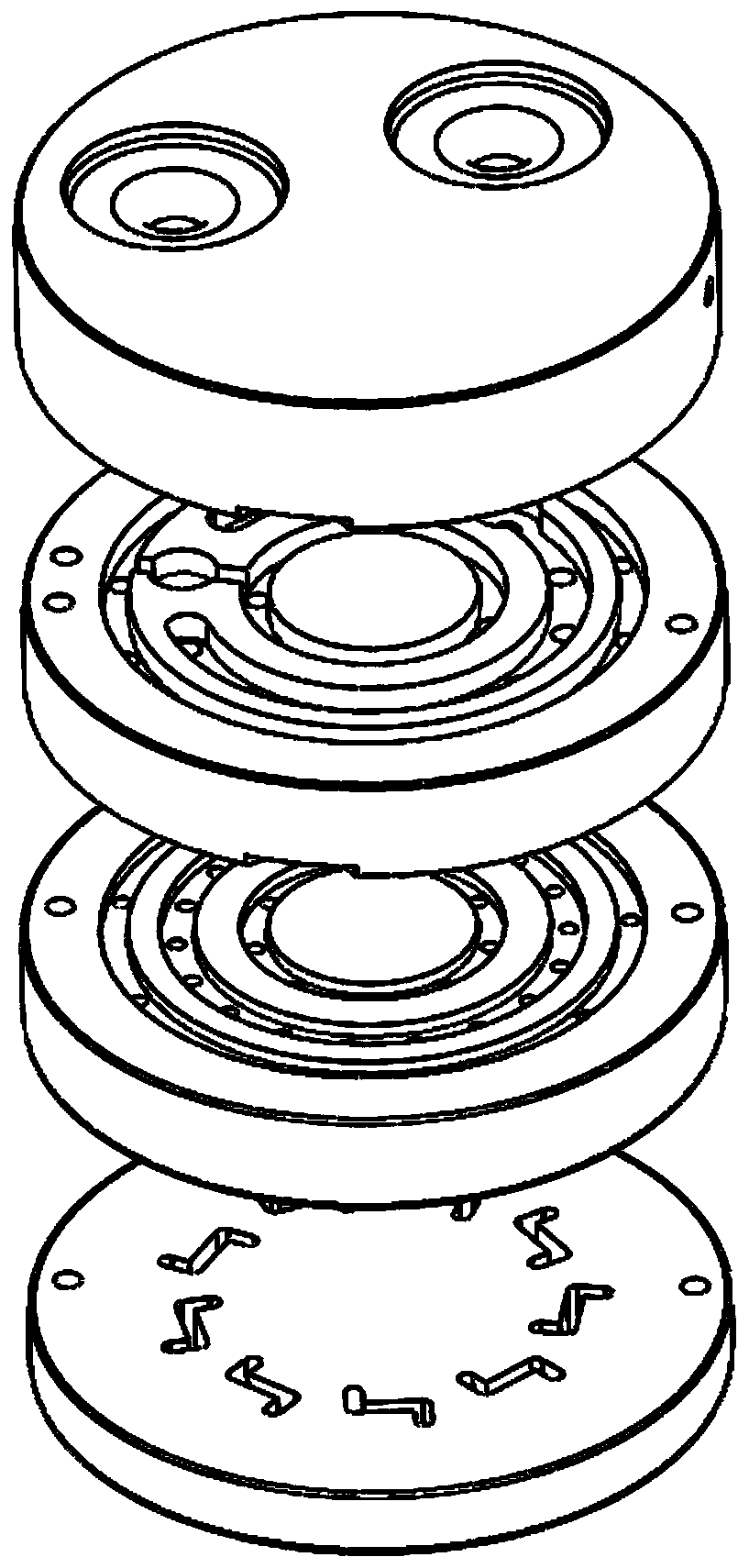

Image

Examples

Embodiment 1

[0050] A preparation method of sports knitted fabric, the steps are as follows:

[0051] (1) Preparation of shaped fibers:

[0052] According to the FDY process, after distributing high viscosity CDP melt (intrinsic viscosity 2.4dL / g) and low viscosity CDP melt (intrinsic viscosity 0.6dL / g) with a mass ratio of 55:45, from the same spinneret The spinneret holes are extruded to produce FDY filaments, that is, special-shaped fibers;

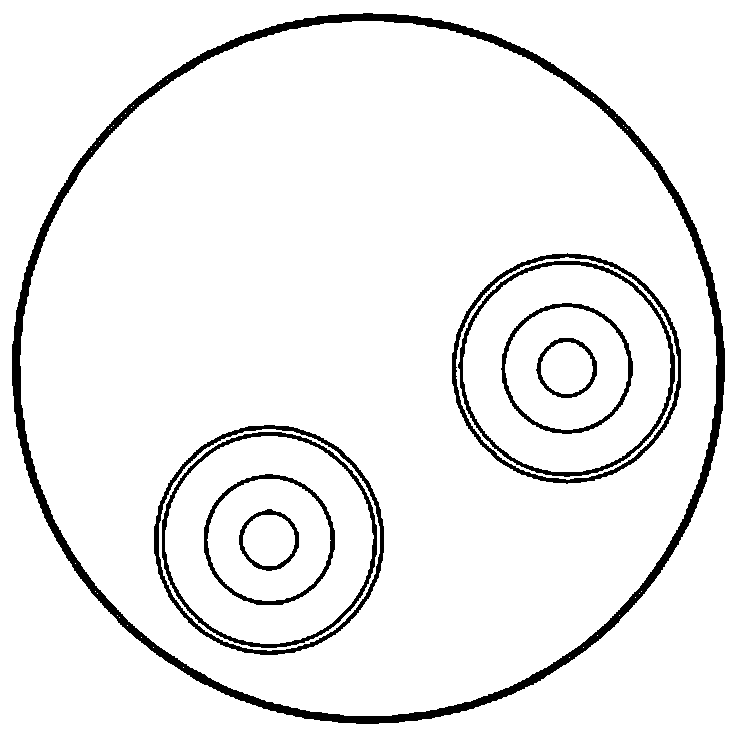

[0053] Such as Figure 8 As shown, the spinneret hole on the spinneret plate is shaped spinneret hole, The shape is composed of a horizontal line and a vertical line I and a vertical line II vertically connected to it; the ratio of the width of the vertical line I to the vertical line II is 1:1.5, and the width of the horizontal line and the vertical line I is the same; the vertical line I and the vertical line The length of II is the same, the ratio of the length of the vertical line I to the horizontal line is 4:10; the ratio of the length ...

Embodiment 2

[0068] A preparation method of sports knitted fabric, the steps are as follows:

[0069] (1) Preparation of shaped fibers:

[0070] According to the FDY process, after distributing high viscosity CDP melt (intrinsic viscosity 2.54dL / g) and low viscosity CDP melt (intrinsic viscosity 0.62dL / g) with a mass ratio of 65:35, from the same spinneret The spinneret holes are extruded to produce FDY filaments, that is, special-shaped fibers;

[0071] The spinneret hole is shaped spinneret hole, The shape is composed of a horizontal line and a vertical line I and a vertical line II connected vertically; the ratio of the width of the vertical line I to the vertical line II is 1:2.1, and the width of the horizontal line and the vertical line I is the same; the vertical line I and the vertical line The length of II is the same, the ratio of the length of the vertical line I to the horizontal line is 4:10; the ratio of the length to the width of the horizontal line is 6:1;

[0072] Th...

Embodiment 3

[0086] A preparation method of sports knitted fabric, the steps are as follows:

[0087] (1) Preparation of shaped fibers:

[0088] According to the FDY process, after distributing high viscosity CDP melt (intrinsic viscosity 2.49dL / g) and low viscosity CDP melt (intrinsic viscosity 0.63dL / g) with a mass ratio of 55:45, from the same spinneret The spinneret holes are extruded to produce FDY filaments, that is, special-shaped fibers;

[0089] The spinneret hole is shaped spinneret hole, The shape is composed of a horizontal line and a vertical line I and a vertical line II connected vertically; the ratio of the width of the vertical line I to the vertical line II is 1:1.9, and the width of the horizontal line and the vertical line I is the same; the vertical line I and the vertical line The length of II is the same, the ratio of the length of the vertical line I to the horizontal line is 5:10; the ratio of the length to the width of the horizontal line is 6:1;

[0090] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com