mppt method with preset performance for wind turbine based on svr and smc

A technology with preset performance and wind turbines, applied in wind power generation, mechanical equipment, engine functions, etc., can solve problems such as poor practicability, low wind capture efficiency, and inability to guarantee system transient and steady-state performance at the same time, and achieve control parameters. less, increase economic efficiency, and simplify the effect of controller design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] This embodiment uses GH Bladed wind power development software to verify the effectiveness of the method provided by the present invention. In order to illustrate the innovation of the present invention, it is compared with the optimal torque control method commonly used in the industry at present

[0081]

[0082] Among them, T gOTC is the electromagnetic torque value given by the optimal torque control algorithm, k opt is the control parameter, ω g is the generator speed, ρ=1.225Kg / m 3 is the air density, R=38.5m is the radius of the wind wheel, C pmax =0.482 is the maximum wind energy capture coefficient, λ opt =8.5 is the best tip speed ratio, n g =104.494 is the transmission ratio of the gearbox.

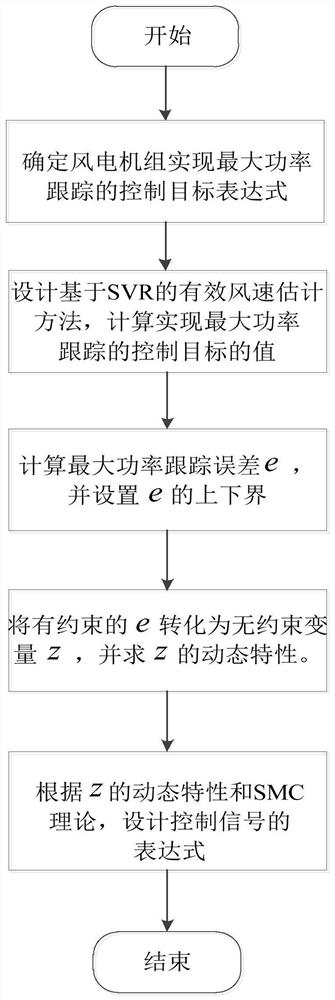

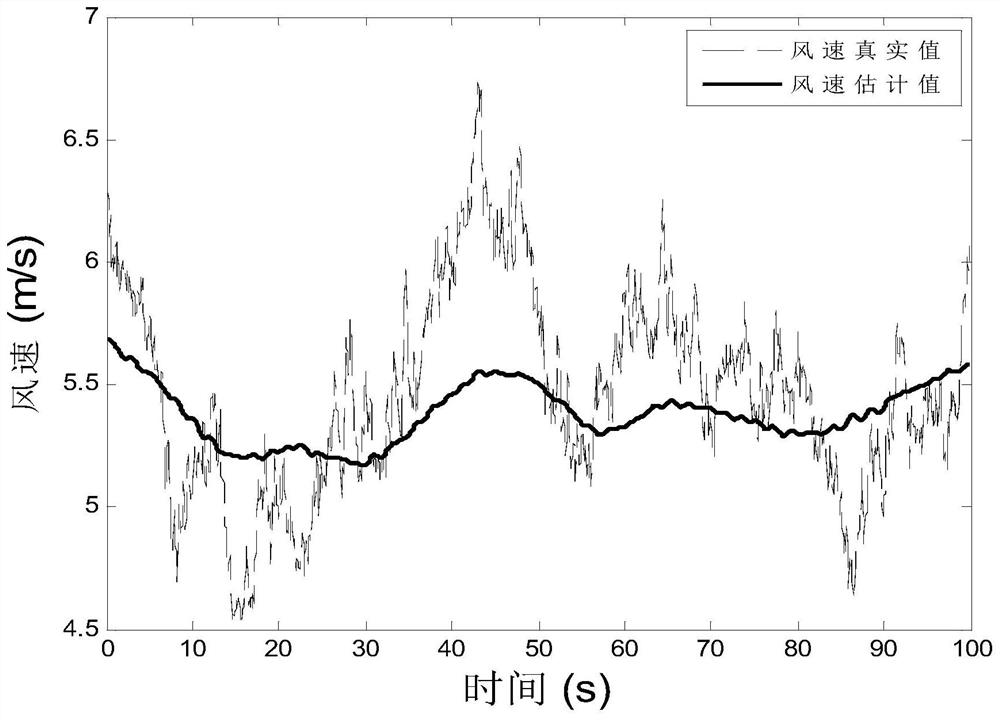

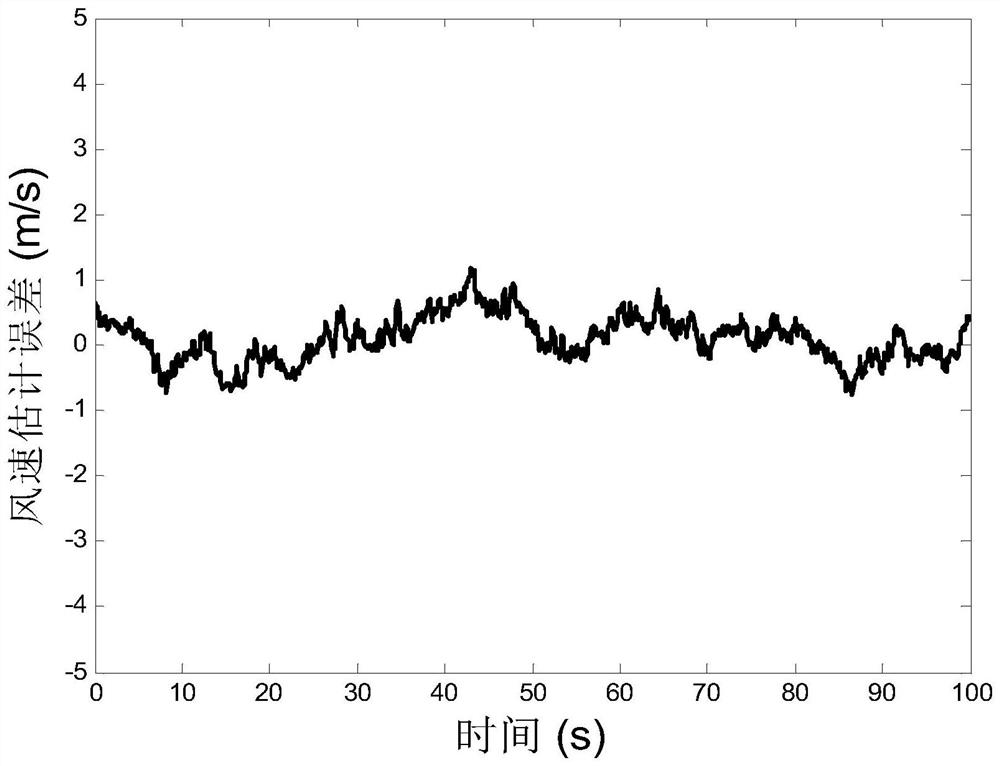

[0083] Such as figure 1 Shown is the design flow chart of the MPPT method for wind turbines with preset performance based on SVR and SMC. First, obtain the control target of the wind turbine to achieve maximum power tracking, and design the effective wind spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com