Automatic iron sheet attaching equipment

An iron sheet and attachment technology, which is applied in the direction of mechanical equipment, material gluing, and connecting components, can solve the problems of inaccurate position of the transparent coating attached to the screen, many transparent coating components, and difficulty in ensuring accuracy. To achieve the effect of streamlined operation, enhanced lamination effect, and simple lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

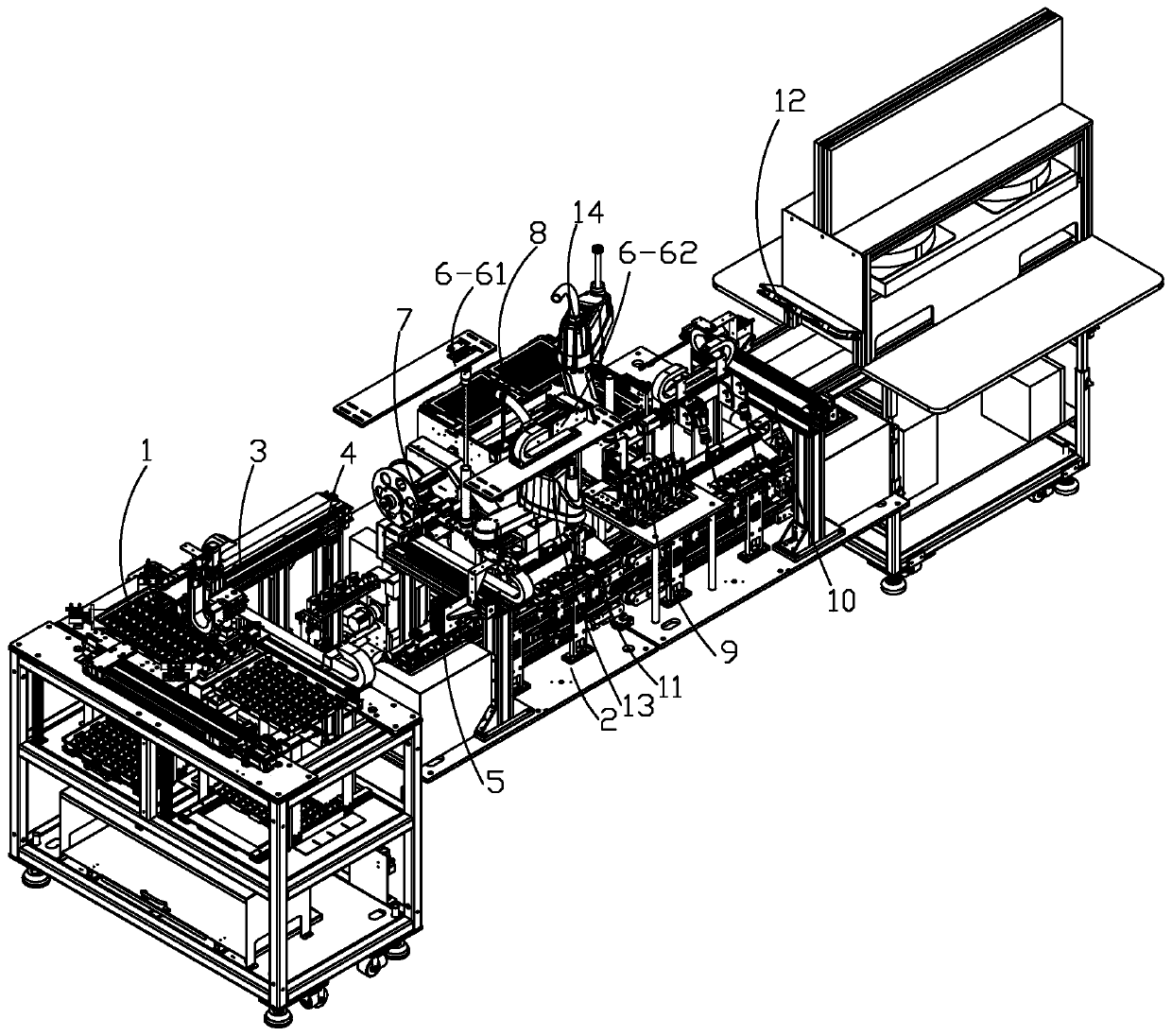

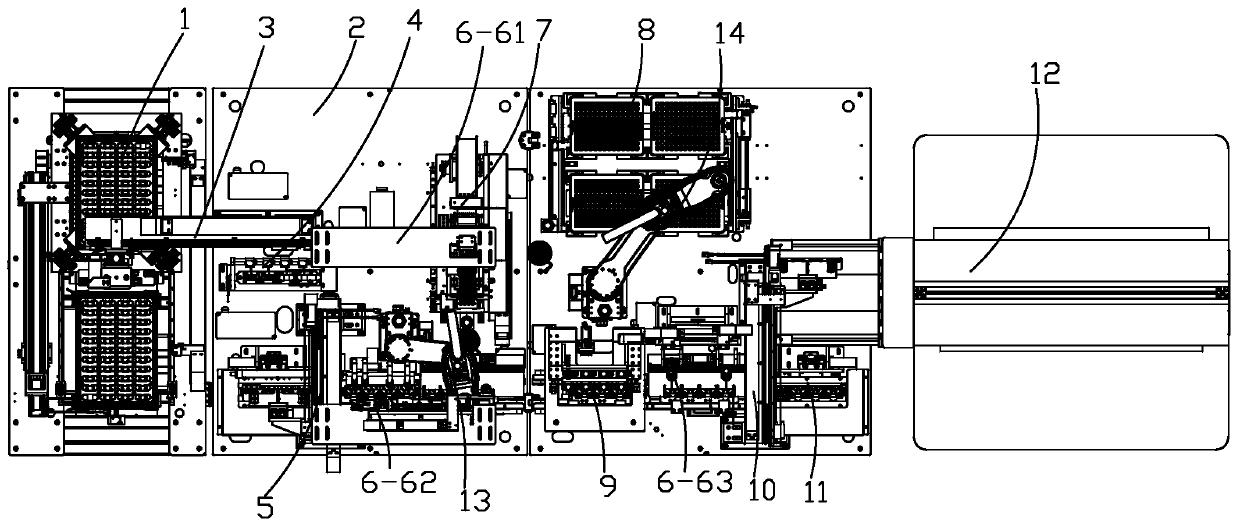

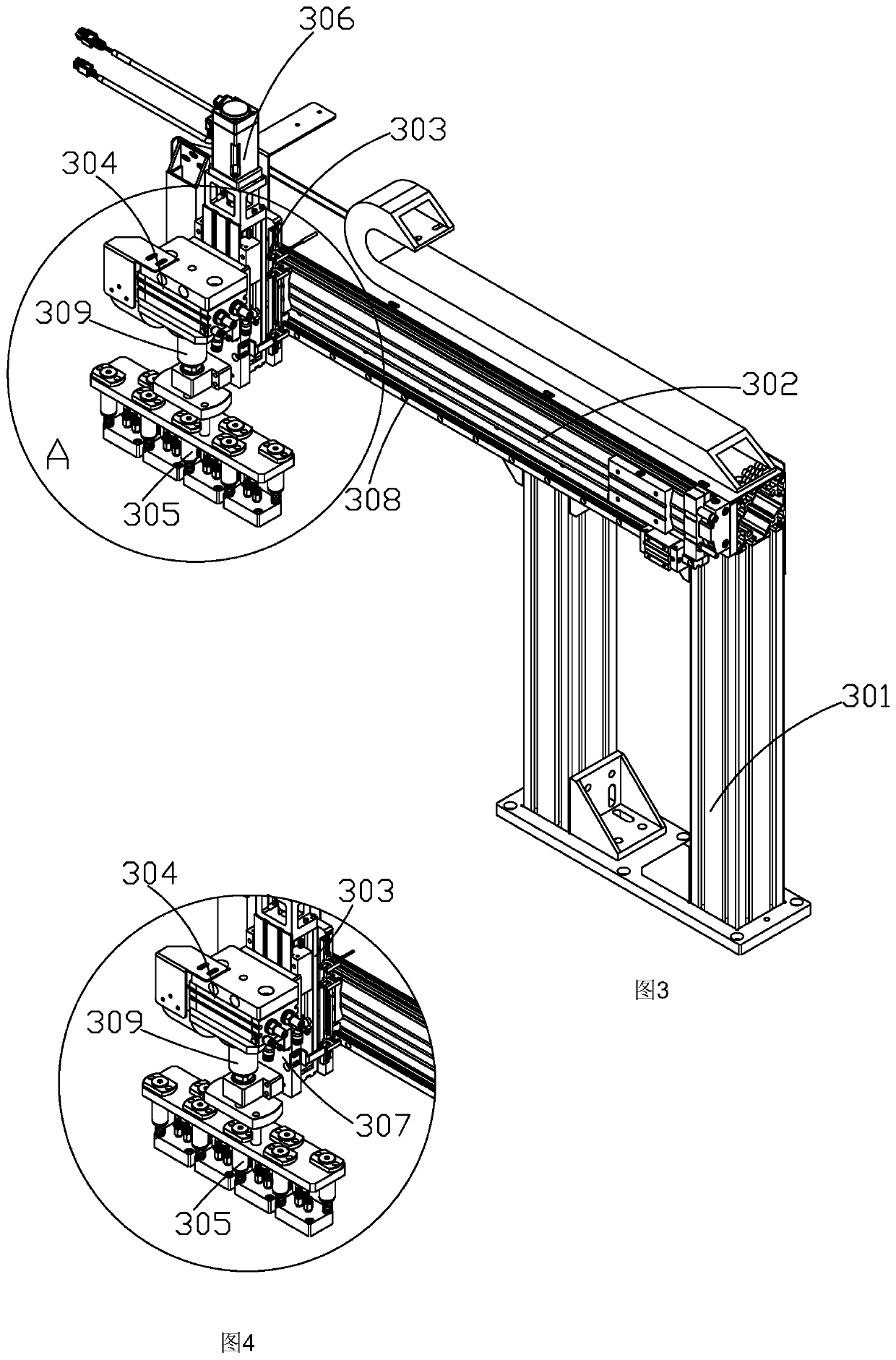

[0038] see Figure 1-2 , the present invention is an automatic attaching device for iron sheets, which is used to complete the lamination of diaphragms, iron sheets and shells, including: shell feeder 1, retrieving mechanism 3 arranged on machine platform 2, and turning mechanism 4. Feeding mechanism 5, CCD detection mechanism 6, diaphragm feeding mechanism 7, iron sheet feeding mechanism 8, pressure maintaining mechanism 9, unloading mechanism 10, jig circulation line 11, discharge line 12, first manipulator 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com