Oxygen pipeline sealing performance improving method

An oxygen pipeline and sealing technology, applied in the aviation field, can solve the problems of surface corrosion of pipeline components, difficulty in removing soapy water, narrow operating space, etc., and achieve the effect of improving anti-corrosion performance, good anti-corrosion effect and firm film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

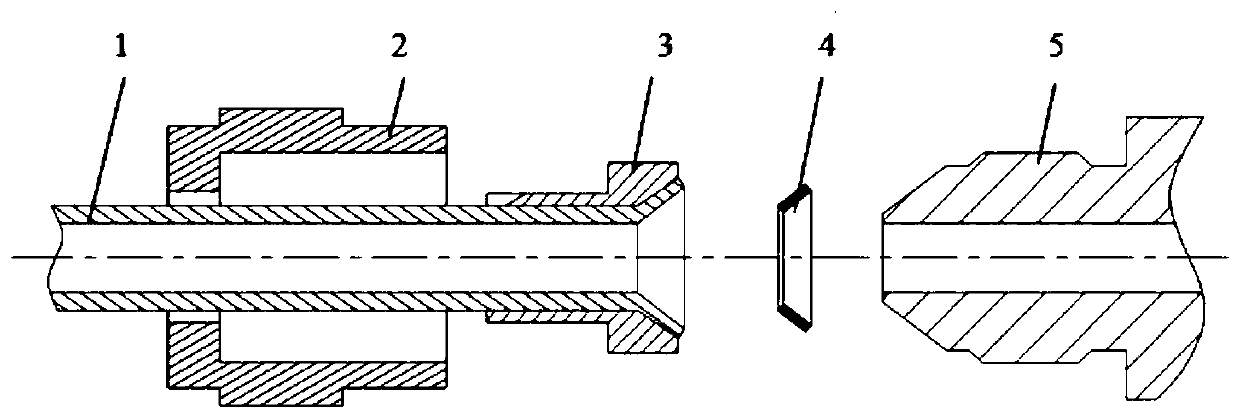

Image

Examples

Embodiment 1

[0034] Use anti-oxidant grease when installing the threaded joint of the oxygen conduit, specifically:

[0035] 1) The brand of antioxidant lipid is Du pont Krytox 240AZ;

[0036] 2) Before applying anti-oxidant grease, carefully wipe the thread connection with a cotton cloth dipped in alcohol;

[0037] 3) Only apply a thin layer of anti-oxidant grease on the outer surface of the thread of the connector. In order to prevent the anti-oxidant grease from falling into the system, no anti-oxidant grease is applied to the first 2 to 3 buckles of the thread;

[0038] 4) After tightening the connecting parts, wipe off the anti-oxidant grease squeezed out with a cotton cloth dipped in alcohol.

Embodiment 2

[0040] The air tightness inspection adopts special gas leak detection products, specifically:

[0041] 1) The brand name of the leak detector is SHERLOCK GAS AND AIR LEAK DETECTOR (TYPE Ⅰ);

[0042] 2) When using, align the bottle mouth with the pipe joint and the threaded seam of the casing nut to extrude a little;

[0043] 3) Observe for 2 minutes to 3 minutes, if there are no bubbles, it means airtight;

[0044] 4) After the test, wipe off the residual leak detection reagent with a lint-free cloth dipped in deionized water,

[0045] 5) Blow dry with compressed air.

Embodiment 3

[0047] After all the oxygen pipelines are installed, brush the hard film slow-release agent on the exposed surface of the pipe joints, specifically:

[0048] 1) The brand name of the sustained release agent is YMS2533;

[0049] 2) Make sure the pipe joints are completely dry and clean before painting;

[0050] 3) Brush the dura mater sustained-release agent with a brush, and dip in an appropriate amount each time when brushing to avoid dripping of the sustained-release agent to adjacent parts;

[0051] 4) Dry the coated slow-release agent naturally for at least 24 hours, and do not touch it during the drying period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com