Negative plate for all-solid-state battery and preparation method and application thereof

A technology of all-solid-state batteries and negative plates, applied in battery electrodes, lithium batteries, electrode carriers/collectors, etc., can solve the problems of high deposition local stress and uneven surface of negative lithium sheets, so as to maintain uniformity and prevent impact The effect of crushing and maintaining stress balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

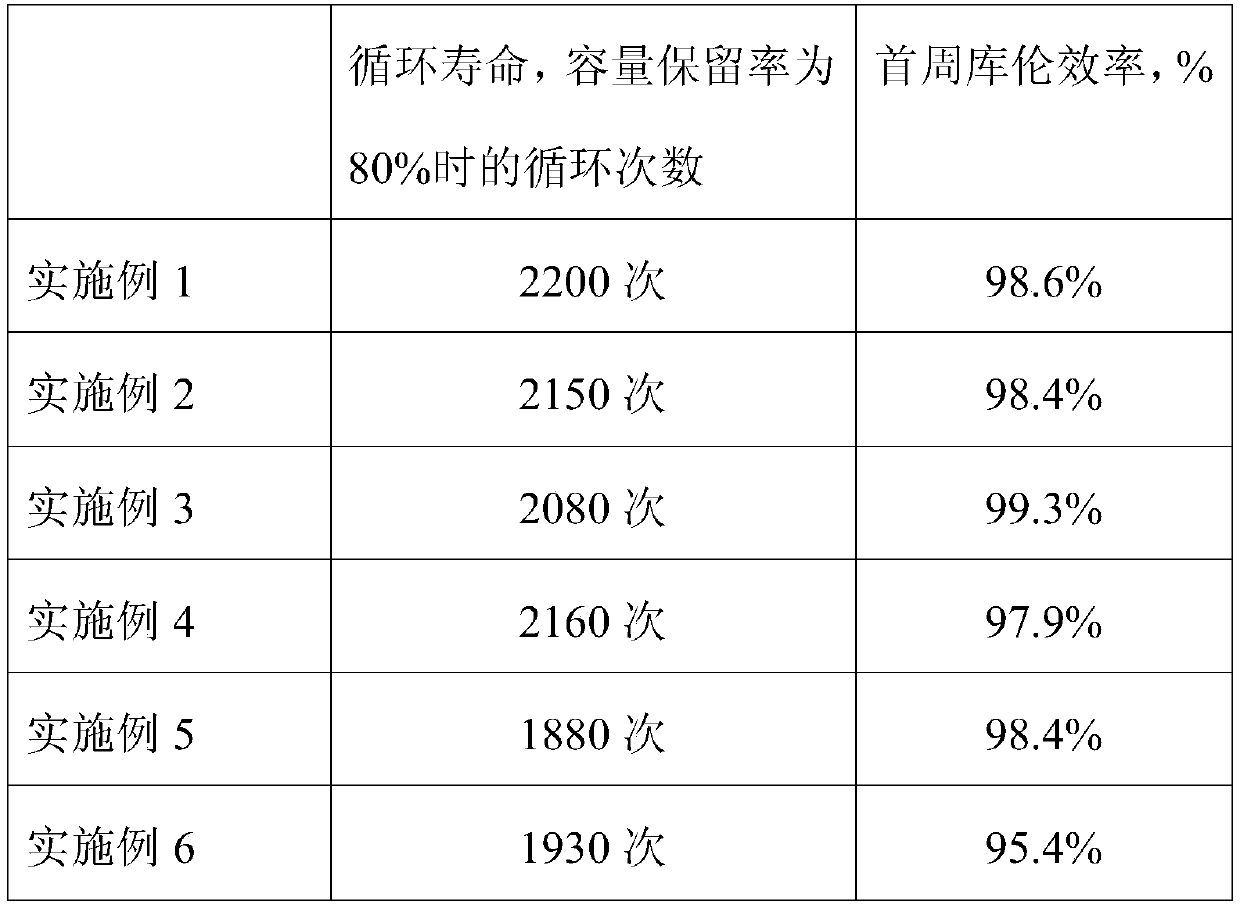

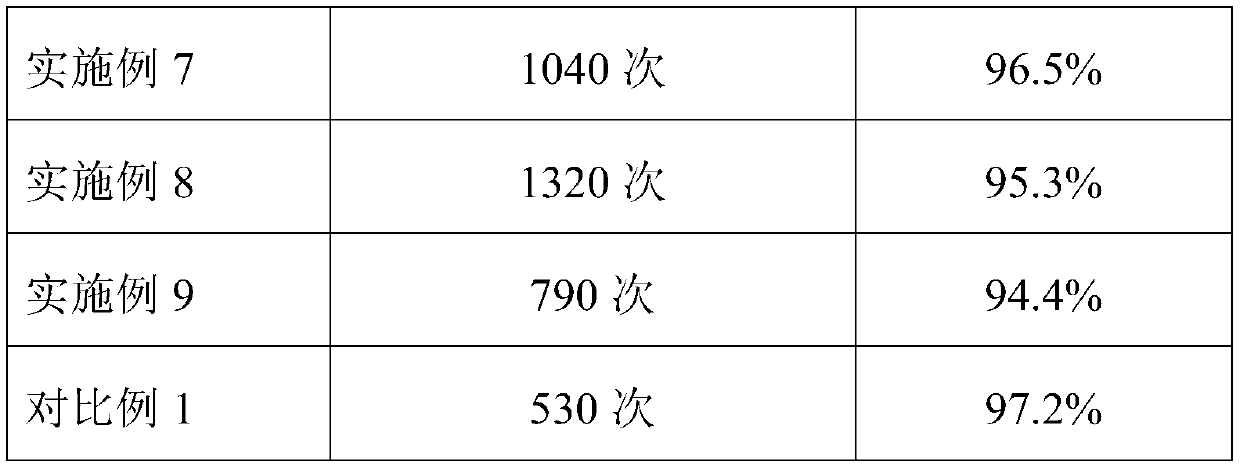

Embodiment 1

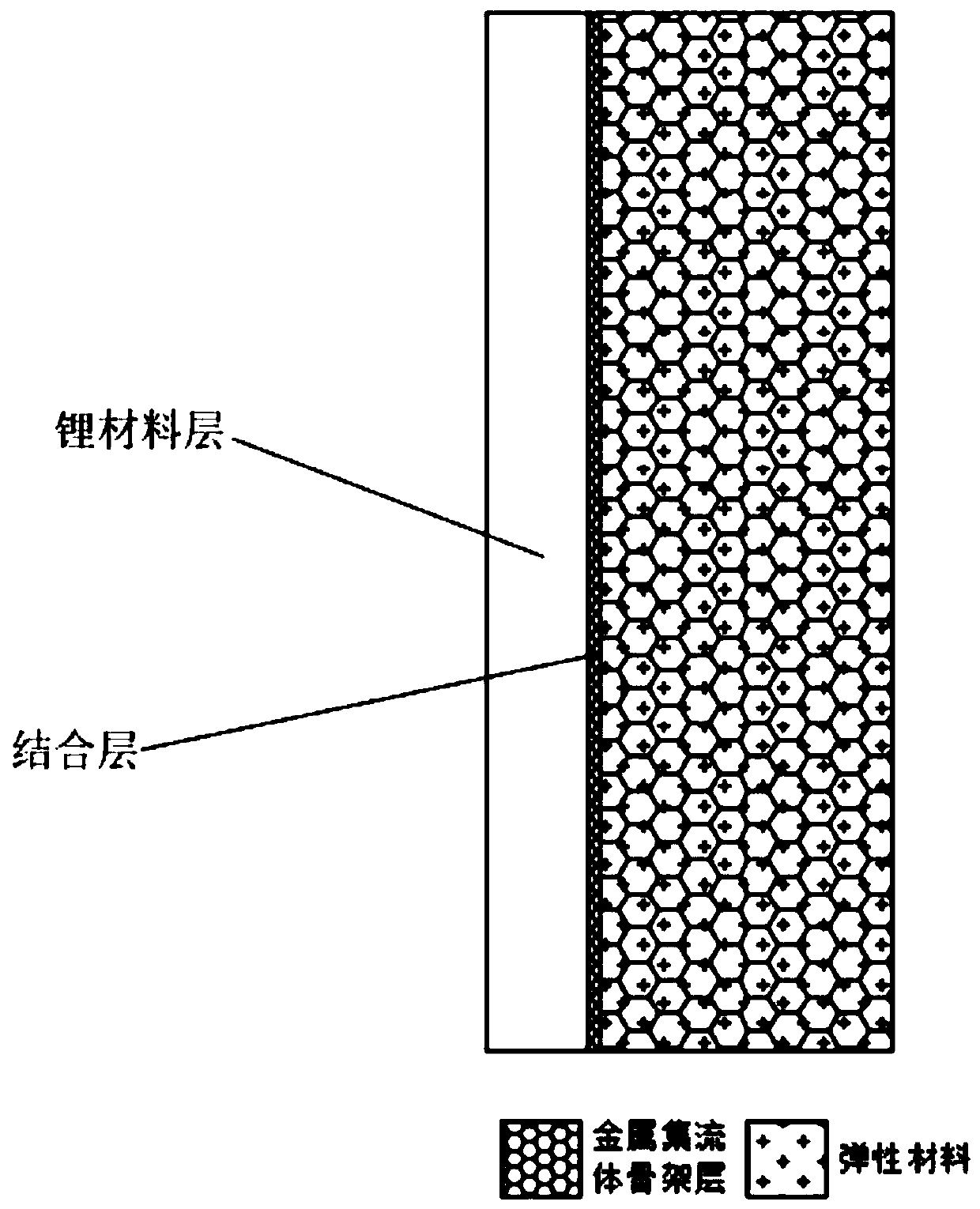

[0057] The negative electrode plate for an all-solid-state battery of the present invention comprises a metal lithium layer and a metal current collector framework layer. The internal gap of the metal current collector framework layer is inlaid with an elastic material; wherein the thickness of the metal lithium layer is 100 μm, and the metal collector The thickness of the fluid framework layer is 1000 μm, the material of the metal collector framework is nickel foam; the porosity of the nickel foam is 40%, the elastic material is cis 1,4-polybutadiene; the elastic modulus of the elastic material It is 5MPa and Poisson's ratio is 0.48.

[0058] The preparation method of the negative plate:

[0059] (a) Melt the elastic material powder, and then inject it into the nickel foam by injection molding at a temperature of 90°C to obtain a composite membrane material;

[0060] (b) The metal lithium layer is hot pressed on the surface of the composite film material obtained in step (a) under ...

Embodiment 2

[0062] The negative electrode plate for the all-solid-state battery of the present invention comprises a metal lithium layer and a metal current collector framework layer. The internal gap of the metal current collector framework layer is inlaid with an elastic material; wherein the thickness of the metal lithium layer is 50 μm, and the metal collection The thickness of the fluid skeleton layer is 500 μm, the material of the metal current collector skeleton is foamed nickel; the porosity of the foamed nickel is 40%, the elastic material is ethylene propylene copolymer; the elastic modulus of the elastic material is 8MPa, Poisson The ratio is 0.52.

[0063] The preparation method of the negative plate:

[0064] (a) Melt the elastic material powder, and then infiltrate into the foamed nickel by injection molding at a temperature of 110°C to obtain a composite membrane material;

[0065] (b) The metal lithium layer is hot-pressed on the surface of the composite film material obtained i...

Embodiment 3

[0067] The negative electrode plate for an all-solid-state battery of the present invention comprises a lithium alloy layer and a metal current collector framework layer. The internal gap of the metal current collector framework layer is inlaid with an elastic material; wherein the thickness of the lithium alloy layer is 20 μm, and the metal collector The thickness of the fluid skeleton layer is 50μm, the material of the metal current collector skeleton is nickel foam; the porosity of the nickel foam is 30%, the elastic material is polyisobutylene; the elastic modulus of the elastic material is 10MPa, and the Poisson's ratio is 0.54.

[0068] The preparation method of the negative plate:

[0069] (a) Melt the elastic material powder, and then infiltrate into the foamed nickel by injection molding at a temperature of 200°C to obtain a composite membrane material;

[0070] (b) Hot-pressing the lithium alloy layer on the surface of the composite film material obtained in step (a) at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com