Printed circuit board and manufacturing method thereof and terminal

A technology of printed circuit boards and printed circuits, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of debugging radio frequency printed circuit boards, and achieve the effect of reducing the size of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned in the background art, in the prior art, data modules are usually designed in a traditional single-sided layout and surface-mounted motherboard. The disadvantage of this type of data module is that, on the one hand, it can only adopt a single-sided layout design, and the module PCB area is large; on the other hand, it will increase the thickness of the product.

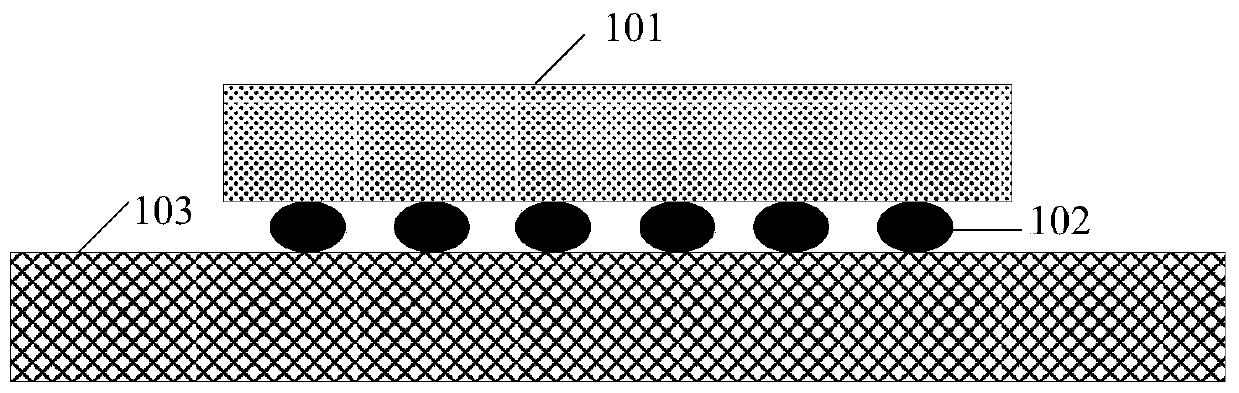

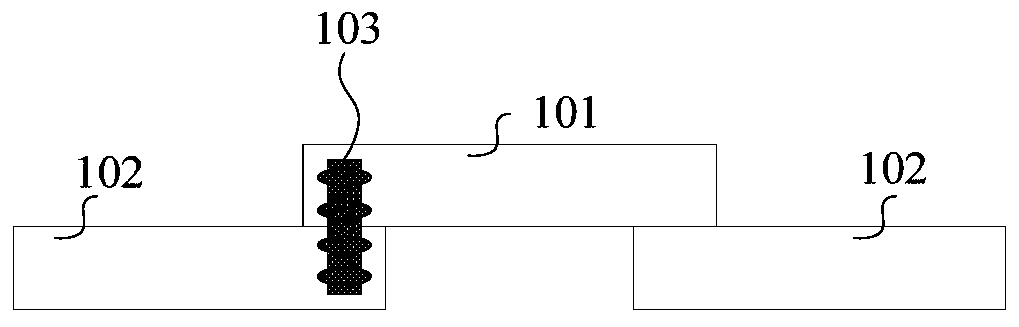

[0029] figure 1 It is a structural schematic diagram of a printed circuit board in the prior art. Such as figure 1 As shown, the current printed circuit board includes a PCB sub-board 101 , a PCB mother board 103 and a plurality of solder balls 102 . In the printed circuit board, the PCB sub-board 101 is surface-attached to the PCB mother board 103 and fixed by solder balls 102 , so the cost is relatively low. However, because this assembly method can only be laid out on one side, the area is too large, and the PCB layout area may even be doubled, and the PCB area of the data module obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com