Industrial method for preparing pickled Chinese cabbage product by fermenting green mustard

A mustard and sauerkraut technology, applied in the food field, can solve the problems of insufficient greenness, pollution, choking, etc., and achieve the effects of enriching nutrients and flavor, slowing down the fermentation speed, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

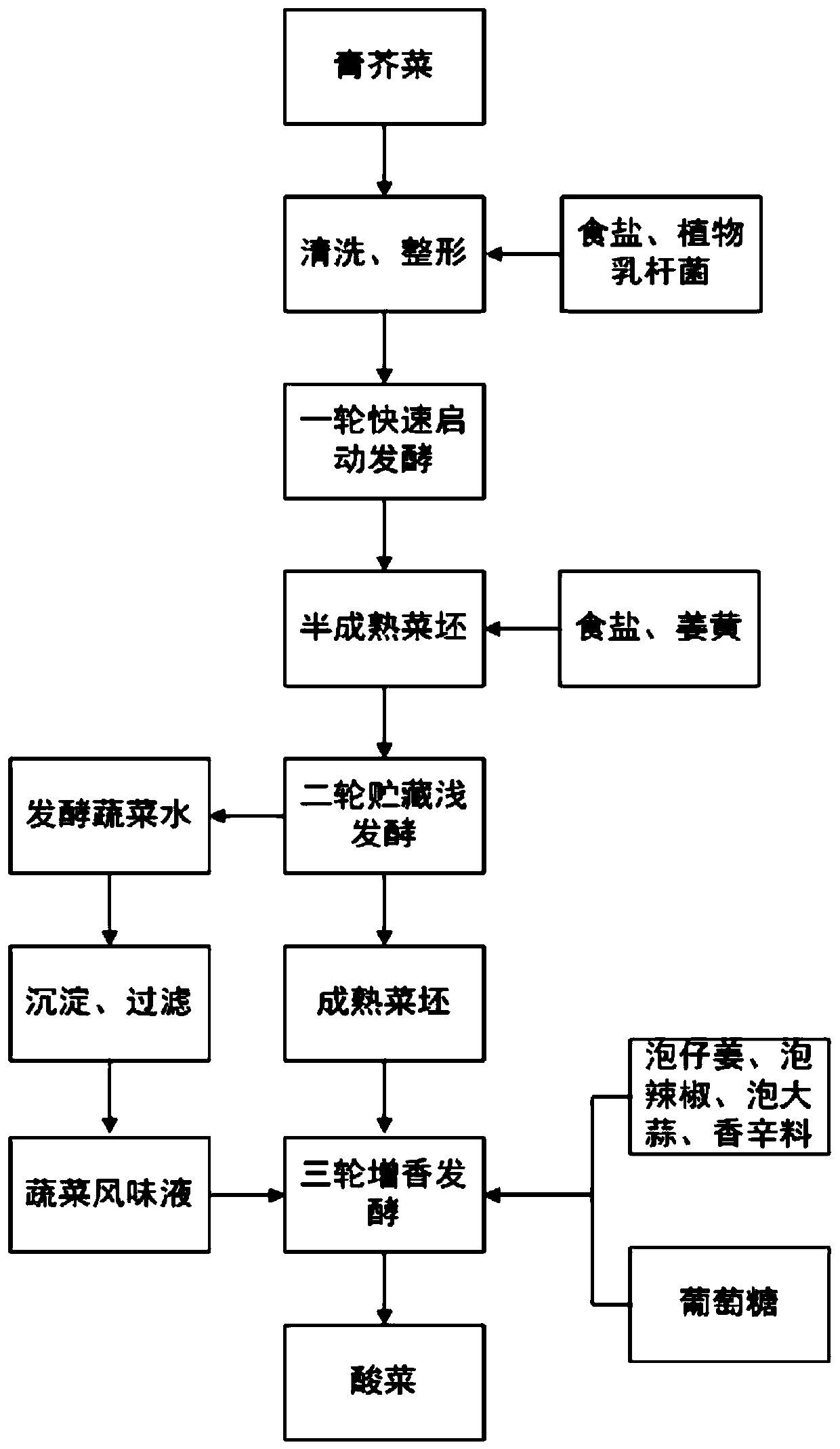

[0029] An industrial preparation method for fermenting green mustard greens to prepare sauerkraut products, comprising the following steps:

[0030] (1) Material selection: select mustard greens with fresh green color and no pests and diseases, remove roots, old skin, etc., and clean them;

[0031] (2) The first round of quick-start fermentation: the green mustard in the step (1) is weighed in parts by weight, 100t is put into the salting pool, 3t of salt is added, and the mode of one layer of vegetables and one layer of salt is used to stack, Mix green mustard and salt evenly, then sand seal and ferment for 20 days to obtain semi-mature green mustard; sand seal means that after the green mustard enters the pool, cover the surface of the green mustard with 2 layers of food-grade PE film, and cover the film with double A layer of waterproof rain cloth is covered with a certain thickness of sand on the waterproof rain cloth to seal the saline pool. The capacity of the saline po...

Embodiment 2

[0035] An industrial preparation method for fermenting green mustard greens to prepare sauerkraut products, comprising the following steps:

[0036] (1) Material selection: select mustard greens with fresh green color and no pests and diseases, remove roots, old skin, etc., and clean them;

[0037] (2) The first fast start fermentation: the green mustard in step (1) is weighed in parts by weight, and 150t is put into the salting pond, and 6t of salt is added to allow the salt and green mustard to be evenly distributed, and the fermentation is more sufficient, and then Sand sealing and fermenting for 25 days to obtain semi-mature vegetable base. The capacity of the saline pond is 150t. Said sand sealing means that after the mustard greens enter the pool, two layers of food-grade PE film are covered on the surface of the green mustard greens, a double-layer waterproof rain cloth is covered on the film, and sand of a certain thickness is covered on the waterproof rain cloth to p...

Embodiment 3

[0042] An industrial preparation method for preparing sauerkraut products by fermenting green mustard greens, which comprises the following steps: (1) material selection: select green mustard greens with green and fresh color and no pests and diseases, remove roots, old skins, etc., and clean them;

[0043] (2) The first round of fast start fermentation: the green mustard in the step (1) is weighed in parts by weight, and 200t is put into the salting pond, and 10t of salt is added, so that the salt and the green mustard are evenly distributed, and the fermentation is more sufficient. Then sand seal and ferment for 30 days to obtain semi-mature vegetable base.

[0044] The amount of added salt is 5% in terms of the quality of mustard greens. The capacity of the saline pond is 200t. Said sand sealing means that after the mustard greens enter the pool, two layers of food-grade PE film are covered on the surface of the green mustard greens, a double-layer waterproof rain cloth is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com