Chicken house air purifying equipment

A technology of air purification equipment and chicken coops, which is applied in the field of breeding equipment, can solve the problems of easy fermentation of chicken manure, poor feeding conditions, and high construction investment, and achieve the effects of reducing air pollution, delaying fermentation speed, and improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

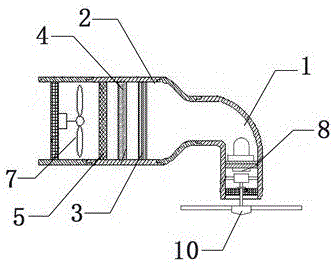

[0033] Such as figure 1 As shown, a kind of chicken house air purification equipment comprises a connected circulating air chamber one 1 and a circulating air chamber two 2, the circulating air chamber one 1 is arranged in the vertical direction, the circulating air chamber two 2 is arranged in the horizontal direction, and the circulating air chamber The diameter of cavity one 1 is smaller than the diameter of circulating air cavity two 2, and several purification nets are arranged in circulating air cavity two 2, and the purification nets are arranged along the vertical direction. Two fans 7 are fixedly connected to the inner wall of the circulating air cavity two 2, and the two fans 7 are arranged along the horizontal direction, and each of the purification nets is arranged in front of the two fans 7. The bottom of the circulating air chamber-1 is provided with a fan-10, which is driven by a motor. The motor is arranged inside the circulating air chamber-1, and the fan-10 i...

Embodiment 2

[0036] polyaldehyde foam Synthesized by:

[0037] First vacuum dehydrate the polyether glycol, and then add polyacetal resin, dimethylol propionic acid and triethylamine in a molar ratio of 1:1.5:0.5:0.2 to the four In the mouth bottle, close the feeding port. Keep the temperature in a water bath at 50°C for 30 minutes until the reaction materials are completely dissolved, then add isophorone diisocyanate with a molar ratio of 1:0.8, react at 75°C for 2-3 hours, and determine by di-n-butylamine titration At the end of the reaction, cool down to 70°C, add 1,4-butanediol and polyoxyethylene ether at a molar ratio of 1:1:1.2 for chain extension reaction for 2 hours, and add 2.5% (mass ratio) of trimethylolpropane for crosslinking Modified for 1 hour to obtain a polyurethane prepolymer, add 20% mass ratio of acetone during the reaction to adjust the viscosity, cool the prepolymer to 40°C and transfer it to a dispersion bucket, add water to emulsify under high-speed stirring, an...

Embodiment 3

[0039] The preparation method of 3-aminotriethoxysilane-nanometer silicon is as follows:

[0040] Weigh 300 mg of Si nanoparticles (particle size 70-90 nm) and ultrasonically disperse them into 50 mL of absolute ethanol, add 10 mL of 3-aminotriethoxysilane dropwise, after ultrasonic treatment, heat at reflux at 70 °C for 3 h. The excessive 3-aminotriethoxysilane is removed through several times of centrifugation and washing to obtain 3-aminotriethoxysilane-nano silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com