Production method of mushroom soup seasoning taking bone soup as raw material

A production method and seasoning technology, applied in the direction of food science, etc., can solve the problems of long time-consuming, complicated process of boiling mushroom soup, unsuitable for industrial production, etc., and achieve the goal of improving production efficiency, benefiting health and having a long aftertaste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Enzymolysis condition optimization

[0025] 1. Experimental steps

[0026] First, optimize the enzymatic hydrolysis conditions, including enzyme amount, pH value, and pressure. 100g of chicken skeletons are cleaned, cut into small pieces, put into an autoclave, and then add 1kg of water. Add 0.01, 0.02, 0.03g of alkaline protease respectively, adjust pH7.0, pH7.5, pH8.0 with 1mol / L hydrochloric acid, raise the temperature to 55°C, seal the autoclave, and fill it with compressed air to increase the pressure respectively To 0.2, 0.4, 0.6MPa, enzymatic hydrolysis for 1 hour.

[0027] 2. Results Analysis

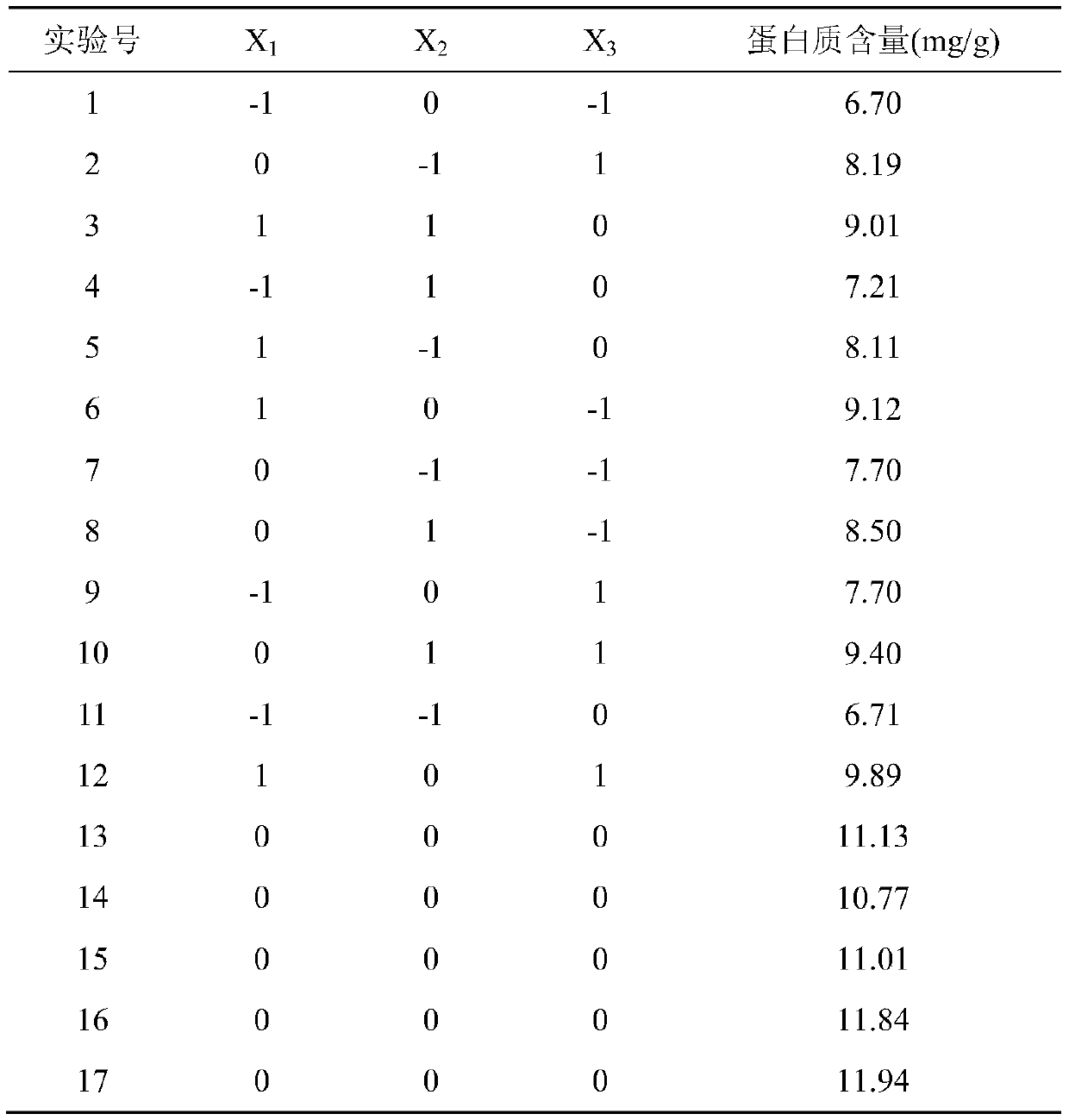

[0028] Response surface analysis adopts a three-factor three-level design, a total of 17 groups of experiments are carried out, factor X 1 is the amount of alkaline protease, the three levels are 0.01g, 0.02g, 0.03g respectively; factor X 2 For enzymatic hydrolysis pH, the three levels are 7.0, 7.5, 8.0; factor X 3 For extraction pressure, the three lev...

Embodiment 2

[0038] 1. Experimental steps

[0039] 1. Prepare the concentrated bone broth of this application

[0040] (1) Broken livestock and poultry bones with a bone cutter, put them into an autoclave, add water at 10 times the weight of the bones, add alkaline protease at 0.028% of the weight of the bones, adjust the pH to 7.6, heat up to 55°C, and The kettle was sealed, filled with compressed air to increase the pressure to 0.45MPa, and enzymatically hydrolyzed for 1 hour;

[0041] (2) After the enzymatic hydrolysis, directly raise the temperature to 120°C, extract under high pressure for 3 hours, then lower the temperature to 90°C, filter through an 80-mesh stainless steel screen to obtain chicken bone broth, and discard the bone residue.

[0042] (3) Concentrate the filtered chicken bone broth by 10 times in vacuum to obtain 100 g concentrated chicken bone broth in total, and detect the protein content.

[0043] 2. Existing extraction process to prepare bone broth

[0044] (1) C...

Embodiment 3

[0049] Embodiment 3 prepares mushroom soup seasoning

[0050](1) Broken livestock and poultry bones with a bone cutter, put them into an autoclave, add water at 10 times the weight of the bones, add alkaline protease at 0.028% of the weight of the bones, adjust the pH to 7.6, heat up to 55°C, and The kettle was sealed, filled with compressed air to increase the pressure to 0.45MPa, and enzymatically hydrolyzed for 1 hour;

[0051] (2) After the enzymatic hydrolysis, directly raise the temperature to 120°C, extract under high pressure for 3 hours, then lower the temperature to 90°C, filter through an 80-mesh stainless steel screen to obtain chicken bone broth, and discard the bone residue.

[0052] (3) The filtered chicken bone broth is vacuum concentrated 10 times to obtain 100g concentrated chicken bone broth in total.

[0053] (4) Take 100 parts of concentrated chicken bone soup, add 3 parts of bacteria powder, 0.2 parts of bacteria soup extract, 0.3 parts of emulsifier, 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com