Process for preventing material in storage tank from crystallizing by utilizing thermosyphon principle

A thermosiphon, material technology, applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of easy explosion, lubricating oil mixed into materials, etc., to prevent the crystallization of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

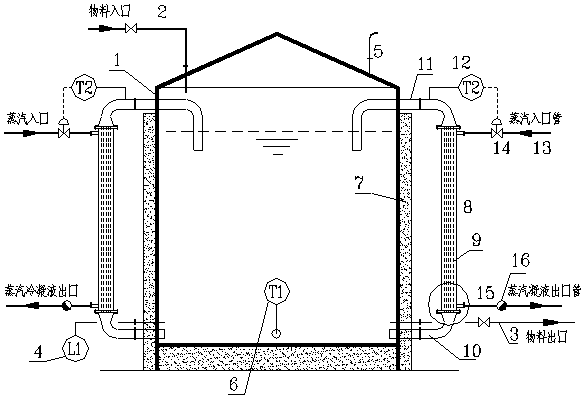

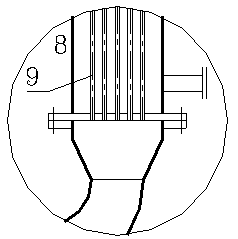

Embodiment 1

[0031] The crystallization temperature of material A is 95°C, the boiling point under normal pressure is 145°C, the diameter of storage tank 1 is 4m, and the storage volume is about 80m 3 . The liquid return thermometer 12 has a diameter of DN250, and the quantity is 2 (symmetrically arranged), the number of thermosiphon small tubes 9 is 22, and the diameters of the material outlet pipe 10 and the material return pipe 11 are DN100. The heating steam parameter is 0.5MPa(g), the saturation temperature is 158°C, the liquid return thermometer 12 and the temperature regulating valve 14 control the heating material to be 140°C.

[0032] Before the material A enters the storage tank, the temperature regulating valve 14 is opened at 30% opening, and the steam is allowed to preheat the thermosiphon heater 1 for 10 minutes before feeding. The temperature of the material A entering the storage tank 1 is 120°C. After entering the storage tank, the steam inlet temperature regulating valve...

Embodiment 2

[0034] The crystallization temperature of material B is 125°C, the boiling point under normal pressure is 170°C, the diameter of storage tank 1 is 5m, and the storage volume is about 120m 3 . The liquid return thermometer 12 has a diameter of DN200, and the number is 4 (symmetrically distributed), the number of thermosiphon small tubes 9 is 18, and the diameters of the material outlet pipe 10 and the material return pipe 11 are DN100. The heating steam parameter is 0.8MPa(g), the saturation temperature is 175°C, and the liquid return thermometer 12 and temperature regulating valve 14 control the heating material to 165°C.

[0035] Before the material B enters the storage tank, the temperature regulating valve 14 is opened at 30% opening, and the steam is allowed to preheat the thermosiphon heater 1 for 10 minutes before feeding. The temperature of the material A entering the storage tank 1 is 140°C. After entering the storage tank, the steam inlet temperature regulating valve...

Embodiment 3

[0037] The crystallization temperature of material C is 80°C, the boiling point under normal pressure is 155°C, the diameter of storage tank 1 is 6m, and the storage volume is about 160m 3. The liquid return thermometer 12 has a diameter of DN300, and the number is 2 (symmetrically arranged), the number of thermosiphon small tubes 9 is 38, and the diameters of the material outlet pipe 10 and the material return pipe 11 are DN150. The heating steam parameter is 0.5MPa(g), the saturation temperature is 158°C, the liquid return thermometer 12 and the temperature regulating valve 14 control the heating material to be 150°C.

[0038] Before the material C enters the storage tank, the temperature regulating valve 14 is opened at 30% to let the steam preheat the thermosiphon heater 1 for 10 minutes before feeding. The temperature of the material A entering the storage tank 1 is 110°C. After entering the storage tank, the steam inlet temperature regulating valve 14 of the thermosipho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization temperature | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com