Fine treatment regeneration system and wastewater classified collection method

A regeneration system and fine treatment technology, which is applied in the field of water treatment in thermal power plants, can solve the problems of increasing wastewater volume, mixing, and large water volume, and achieve the effect of increasing the ion concentration of wastewater and reducing the amount of high-salt wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

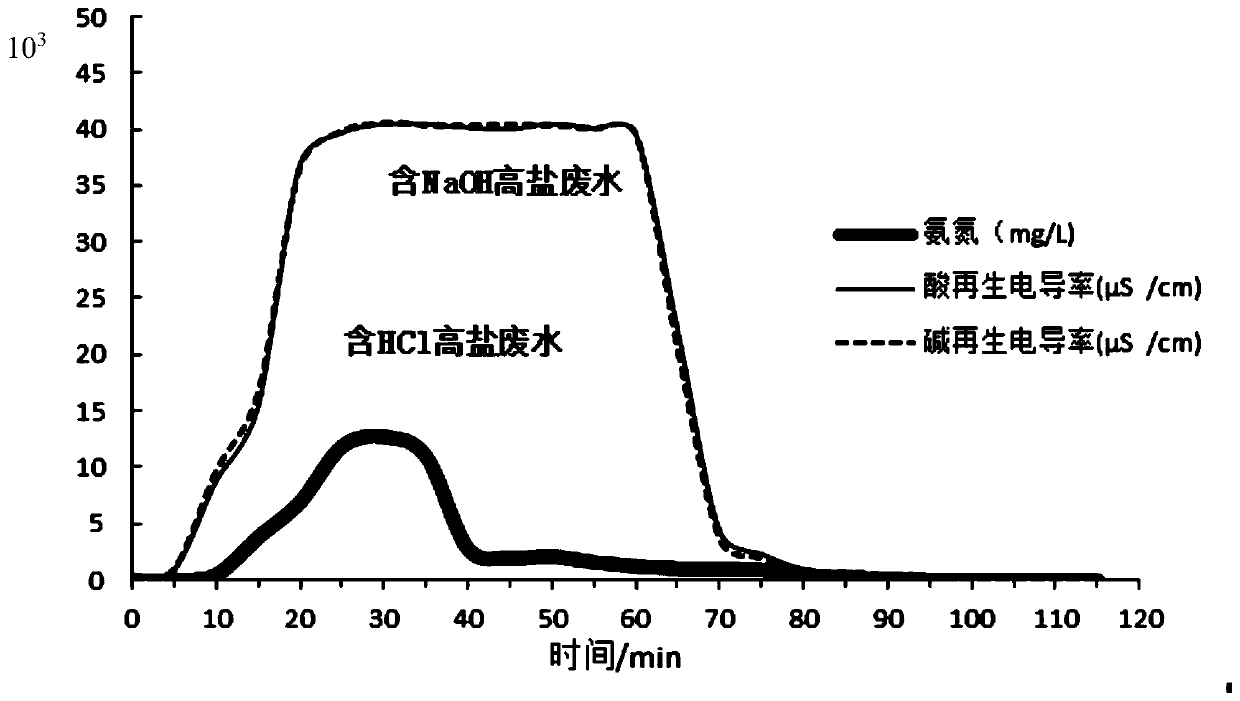

[0034] Such as figure 2 As shown, in the acid regeneration tank, the process time of the refined cation resin acid regeneration process is 60 minutes, and the desalinated water replacement process time is also 60 minutes. The 0-5 minutes of the regeneration process is mainly to drain the water in the acid resin tank, and the conductivity The rate is 0-200μS / cm; about 5-60 minutes after the regeneration starts, the salt content of the regenerated wastewater increases rapidly, the conductivity rapidly rises from 200-4000μS / cm to 35000-38000μS / cm, and the ammonia nitrogen index changes from 0 to 30 minutes 0mg / L rises to 11000-13000mg / L, and drops to 1000-1200mg / L in 30-60 minutes; 60-80 minutes after regeneration starts, the conductivity drops rapidly from 35000-38000μS / cm to about 800-1000μS / cm, ammonia nitrogen Rapid drop from 1000-1200mg / L to 50-100mg / L; 80-120 minutes after the start of regeneration, the conductivity of the regeneration wastewater dropped from 800-1000μS / cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com