Novel tailing mixed soil road base course material and preparation method thereof

A technology of road base and mixed soil, which is applied in the field of road base materials and industrial solid waste treatment. It can solve the problems that road construction cannot be applied on a large scale, the chemical properties of iron tailings are inactive, and the adsorption force of particles is small, so as to achieve easy compaction and stability, solve the poor performance index, improve the effect of adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A new tailings mixed soil road base material, including the following raw materials in parts by mass, 50 parts of iron tailings sand, 50 parts of ordinary soil, 5 parts of cement, 5 parts of lime and 2 parts of ionic soil stabilizer, without polypropylene fiber , its preparation method comprises the following steps:

[0054] (1) After mixing the iron tailings sand, soil, cement and ionic soil curing agent, carry out a compaction test, and measure its optimum moisture content and optimum dry density;

[0055] (2) taking various raw materials according to the required proportioning, mixing the iron tailings sand, soil and lime evenly to obtain a mixture;

[0056] (3) According to the measured optimum water content, add tap water to the ionic soil stabilizer to prepare a dilution, wherein the total amount of water added should be about 1%-2% greater than the optimum water content.

[0057] (4) Add 70% of the diluent to the mixture, stir well, cover the mixture with a plas...

Embodiment 2

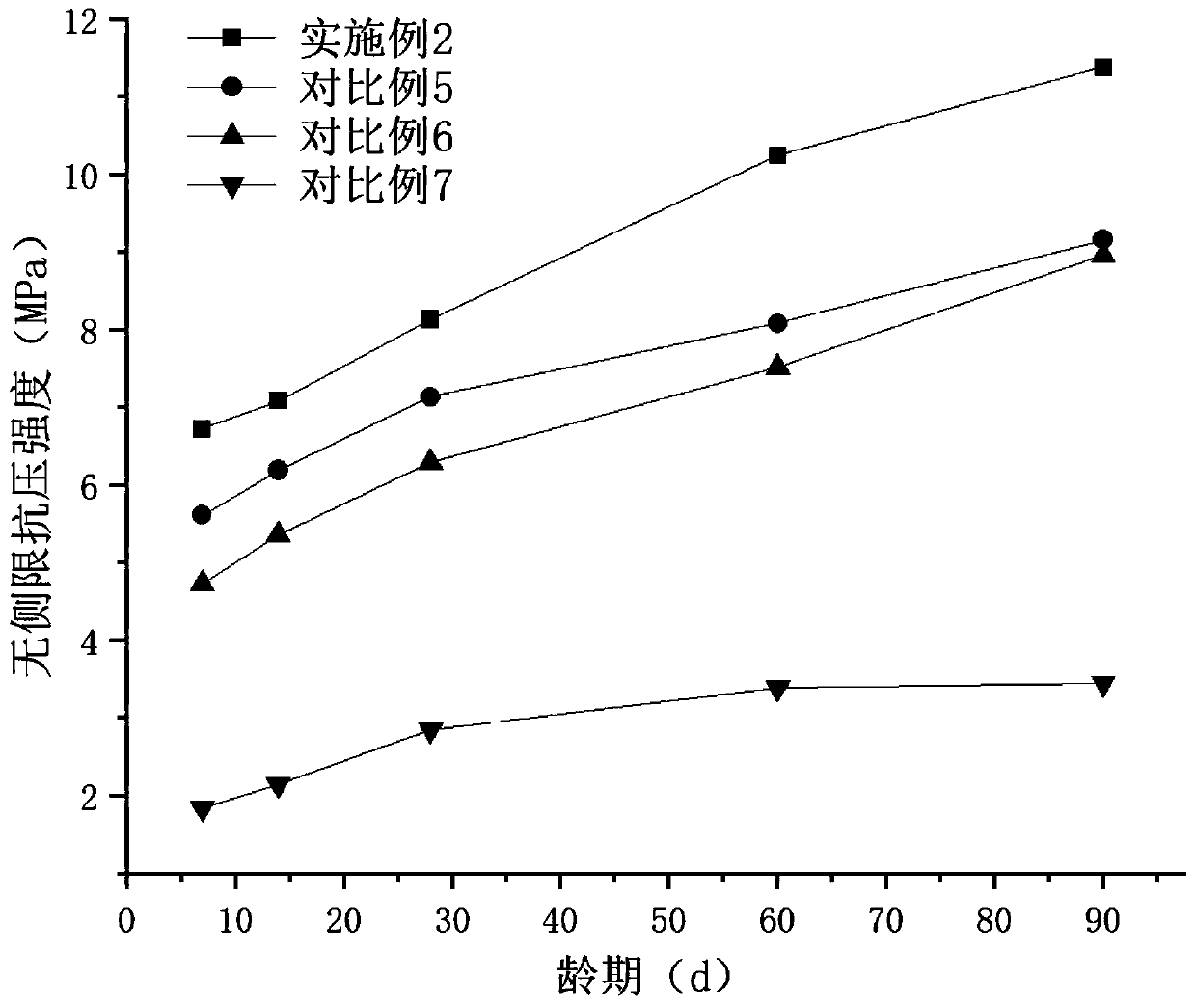

[0072] Example 2 Compared with Example 1, the raw materials, dosage and preparation steps for preparing tailings mixed soil are the same as Example 1. The difference is that the tailings mixed soil prepared in Example 2 was subjected to unconfined compression tests of different ages (7 days, 14 days, 28 days, 60 days, 90 days).

[0073] The specific operation is: divide the tailings mixed soil prepared in Example 2 into five groups according to different ages (7 days, 14 days, 28 days, 60 days, 90 days), and make 6 test pieces for each group and put them into standard curing Box (curing temperature 20±2°C, humidity 95%), after curing for 6 days, 13 days, 27 days, 59 days, 89 days, soak in water for 1 day, dry the surface moisture of the test block, according to the "Highway Engineering Inorganic Binder Stable Material Unconfined compressive strength test.

Embodiment 3

[0087] The tailings mixed soil prepared in Example 1 was subjected to indirect tensile tests (split tests) at different ages (7 days, 14 days, 28 days, 60 days, 90 days), and Example 3 was obtained. The specific operation is: use the reaction force frame and demoulding machine to make 30 test pieces (6 for each age) and put them into the standard curing box (curing temperature 20±2°C, humidity 95%), and curing for 6 days and 13 days respectively , 27 days, 59 days, and 89 days, soak in water for 1 day, wipe off the surface moisture of the test block, and conduct an indirect tensile test (split test) according to the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com