Method for determining iron content in thiourea dioxide

A technology of thiourea dioxide and a determination method, which is applied in the directions of measuring devices, preparation of test samples, color/spectral characteristic measurement, etc., can solve problems such as environmental pollution, human health hazards, and long time required, and achieve fast analysis speed, High accuracy and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

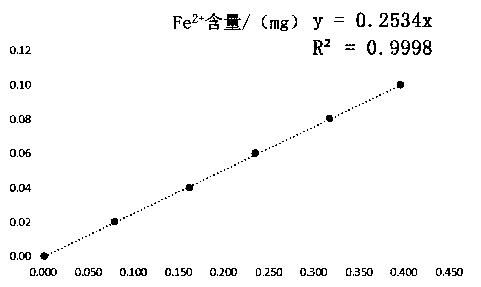

Image

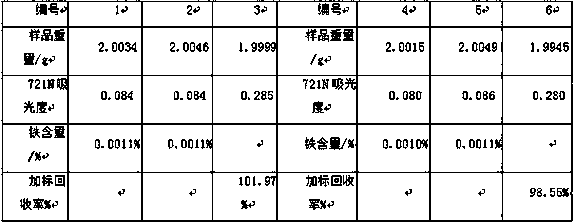

Examples

Embodiment

[0022] A kind of assay method of iron content in thiourea dioxide, comprises the following steps:

[0023] 1) Sample treatment: Weigh 6 groups of the same thiourea dioxide samples (4 groups are used for determination of iron content, and the remaining two groups are used for determination of standard recovery), each group is about 2g of thiourea dioxide (accurate to 0.0001g), The treatment method is as follows: pour thiourea dioxide into a 100mL beaker, add a small amount of water to soak it, add 1mL hydrochloric acid 1+1 solution dropwise, then add about 50mL water to the beaker, heat with an electric furnace until the solution is clear, and continue heating to Evaporate the solution until the remaining solution volume is about 20mL, transfer it to a 100mL volumetric flask for later use;

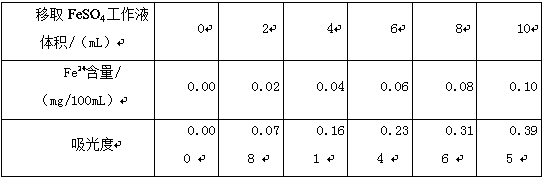

[0024] 2) Preparation of standard solution: prepare 0.1mg / mL FeSO 4 standard solution;

[0025] 3) Determination of the maximum absorption wavelength: Take 10 mL of the iron standard solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com