Husking device

A technology of shell breaking device and shell, which is applied in the direction of shell removal, solid separation, pod removal, etc., can solve the problems of easy loss, time-consuming, inaccurate data analysis, etc., and achieve the effect of convenient packing and ensuring accuracy and integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

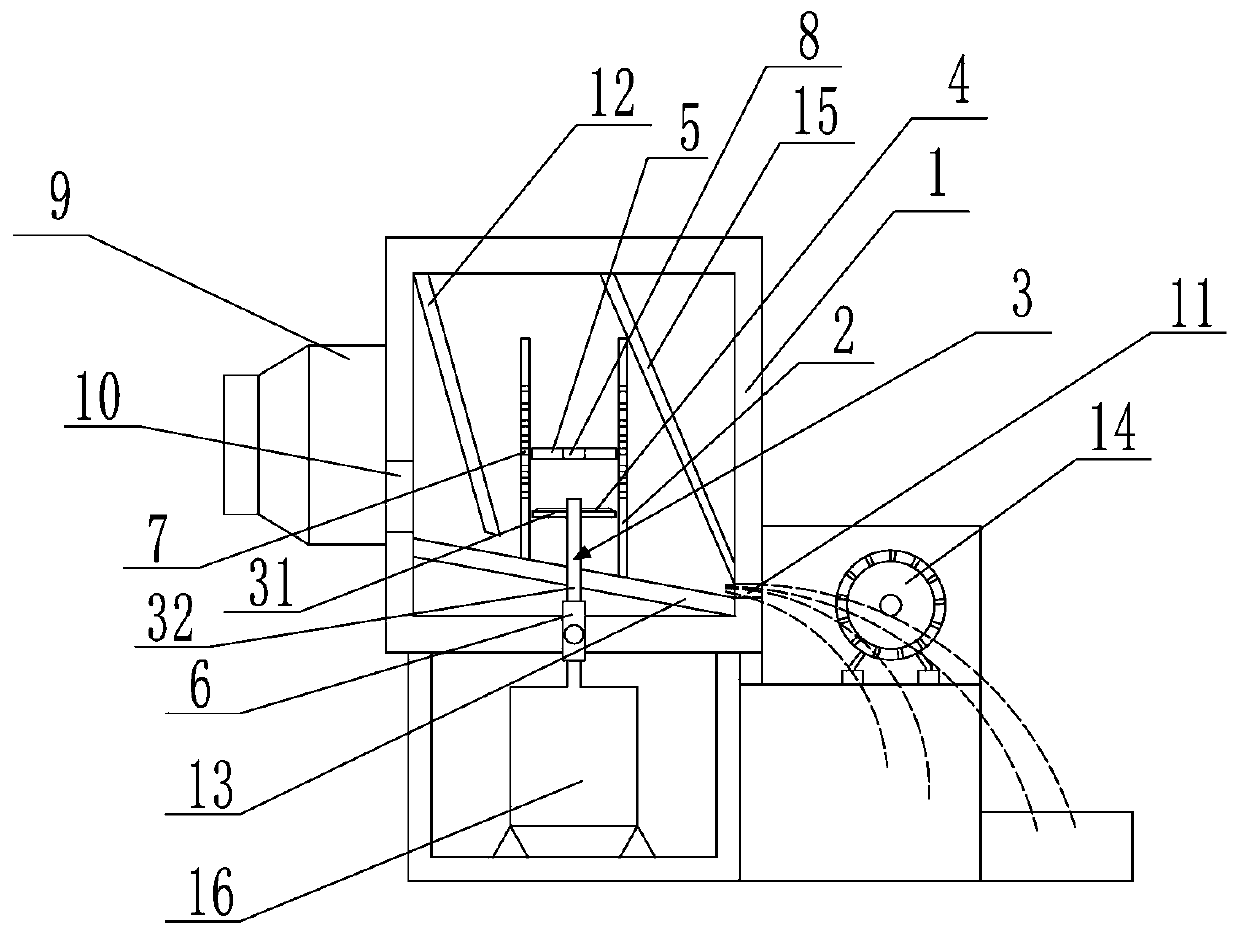

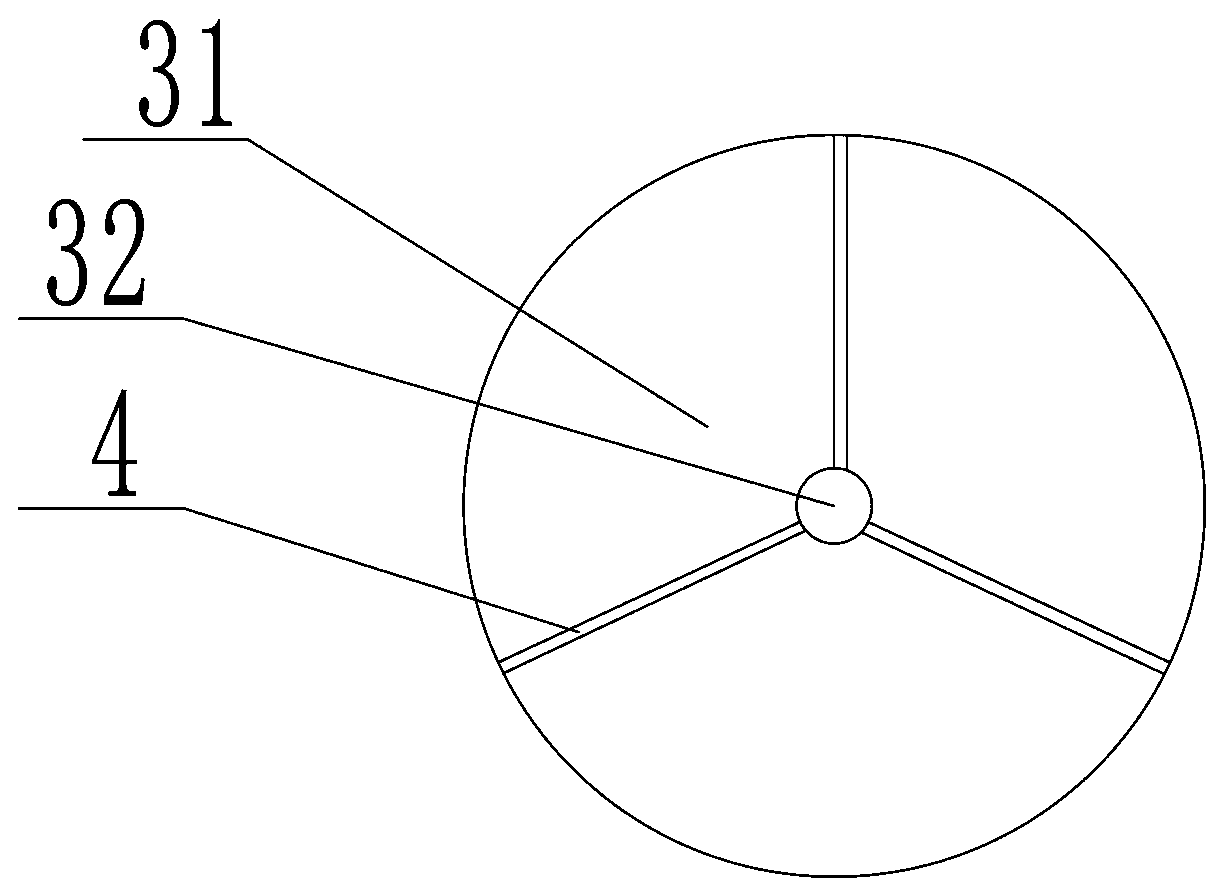

[0028] as attached Figure 1-2 As shown, the present embodiment provides a peeling device, which includes a housing 1, a separation cylinder 2 arranged inside the housing 1, a shell breaking device arranged inside the separation cylinder 2, and a shell breaking device connected with the shell breaking device. The drive motor 16 connected to the device, the cracking device includes a knife rest 3 arranged inside the separation cylinder 2 and more than one blade 4 arranged on the knife rest 3, and more than one separation blade 4 is arranged on the separation cylinder 2. Hole 7, the aperture of the separation hole 7 is 4.8 ~ 5.6mm, the design principle of the aperture size of the separation hole 7 is that the cottonseed shell and cottonseed kernel after the shell can only pass through the separation hole 7, and the whole cottonseed that has not been peeled off cannot pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com