Preparation method of tetrapanax papyriferus extract and pharmaceutical composition containing tetrapanax papyriferus extract

A technology of Chasegrass and extract, applied in the field of preparation method and pharmaceutical composition containing Chasecao extract, can solve the problems of drug resistance and drug residues, reduce breast diseases, extract at low temperature, and improve lactation ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

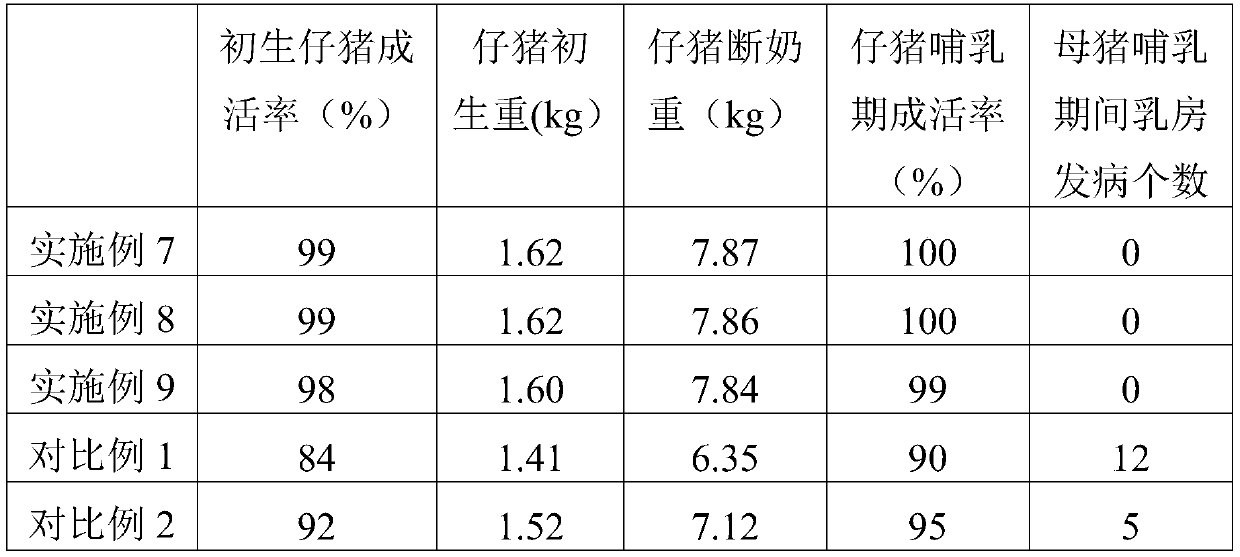

Examples

Embodiment 1

[0023] A preparation method of Chase grass extract, comprising the following steps:

[0024] Step 1. Pulverize Chase Grass, then mix 100g of pulverized Chase Grass particles with 2g of sodium hydroxide, then add it to a ball mill jar, and ball-mill the balls in the ball mill jar; feed liquid nitrogen into the ball mill jar to make Chase Grass Submerge the particles and sodium hydroxide in liquid nitrogen at a temperature of -170°C, and keep the volatile amount of liquid nitrogen and the amount of feed in balance to stabilize the liquid level; start ball milling after 25 minutes of constant temperature, and ball mill for 60 minutes; after ball milling, ball mill the tank Transfer to a vacuum glove box, place it for 24 hours, and collect the ball milling material; the consumption of the ball milling ball is to add 30 ball milling balls per 1g of Datong grass particles; the material of the ball milling tank and the ball milling ball is agate; the speed of the ball milling It is 5...

Embodiment 2

[0029] A preparation method of Chase grass extract, comprising the following steps:

[0030] Step 1: Pulverize Chase Grass, then mix 100g of pulverized Chase Grass particles with 1g of sodium hydroxide, then add it to a ball mill jar, and ball-mill the balls in the ball mill jar; feed liquid nitrogen into the ball mill jar to make Chase Grass Submerge the granules and sodium hydroxide in liquid nitrogen at a temperature of -165°C, and maintain a balance between the volatile amount of liquid nitrogen and the input amount to stabilize the liquid level; start ball milling after 20 minutes of constant temperature, and ball mill for 45 minutes; after ball milling, ball mill jar Transfer to a vacuum glove box, place it for 12 hours, and collect the ball milling material; the consumption of the ball milling ball is to add 40 ball milling balls per 1g of Datong grass particles; the material of the ball milling tank and ball milling ball is agate; the speed of the ball milling 400r / min...

Embodiment 3

[0035] A preparation method of Chase grass extract, comprising the following steps:

[0036] Step 1. Pulverize Chase Grass, then mix 100g of pulverized Chase Grass particles with 3g of sodium hydroxide, then add it to a ball mill jar, and ball-mill the balls in the ball mill jar; feed liquid nitrogen into the ball mill jar to make Chase Grass Submerge the particles and sodium hydroxide in liquid nitrogen at a temperature of -180°C, and keep the volatilization of liquid nitrogen and the amount of feed in balance to stabilize the liquid level; start ball milling after 20 minutes of constant temperature, and ball mill for 40 minutes; after ball milling, ball mill jar Transfer to a vacuum glove box, place it for 12 hours, and collect the ball milling material; the consumption of the ball milling ball is to add 50 ball milling balls per 1g of Datong grass particles; the material of the ball milling tank and the ball milling ball is agate; the speed of the ball milling 450r / min;

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap