A kind of preparation method of tc18 titanium alloy small size bar

A TC18 and small-size technology, which is applied in the field of preparation of TC18 titanium alloy small-size rods, can solve the problems of easy cracking of materials, narrow processing window, and increased number of forging fires, so as to improve the yield, shorten the forging cycle, and improve the uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

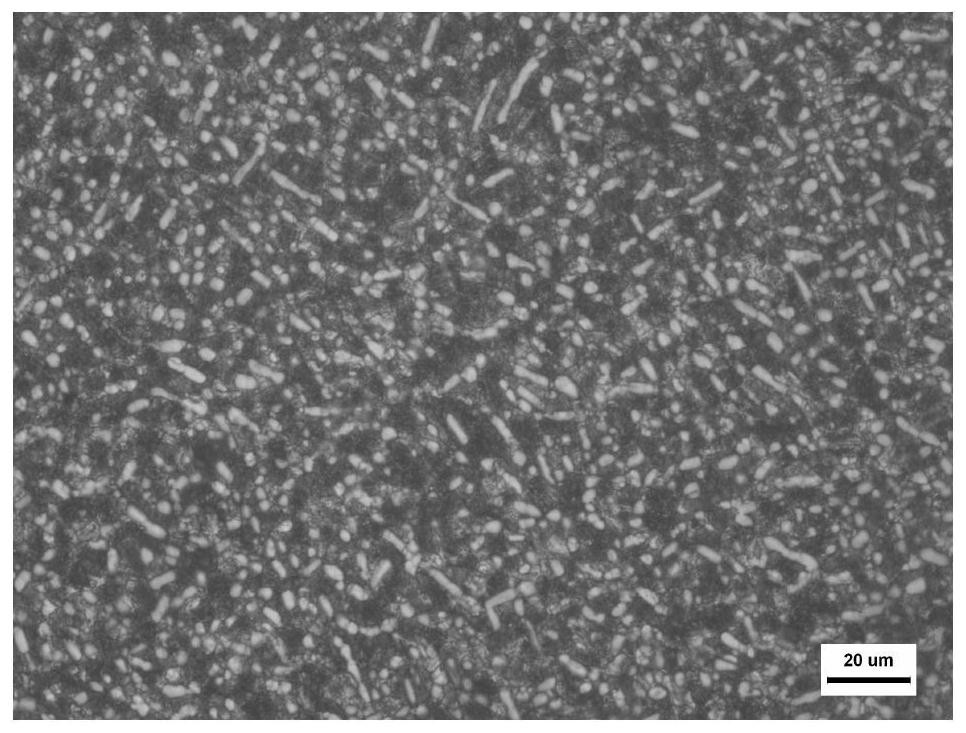

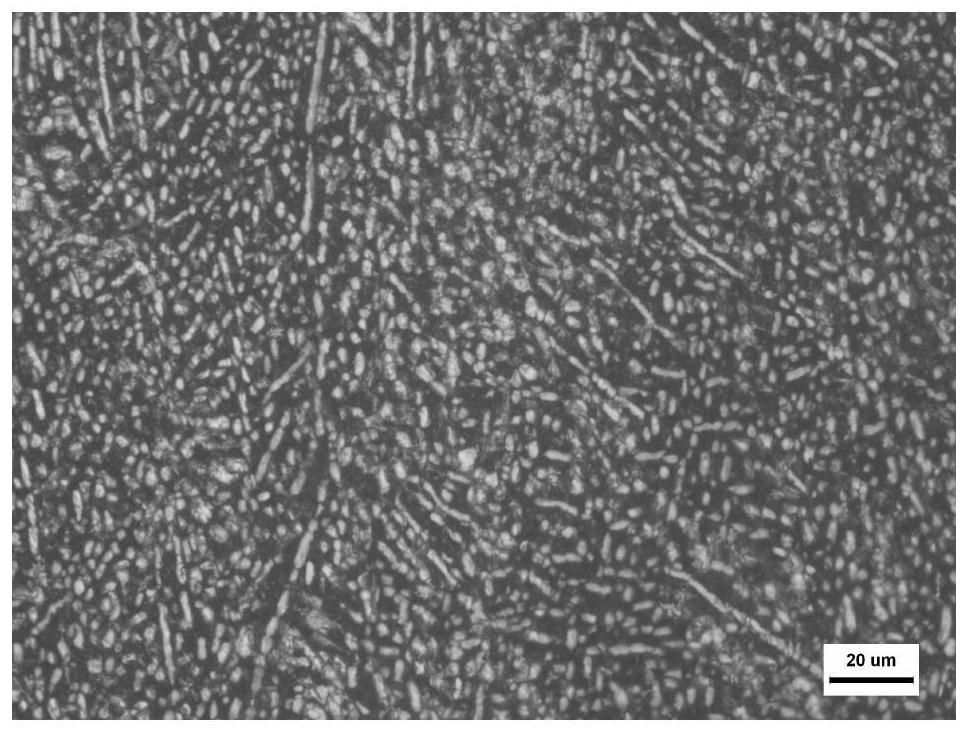

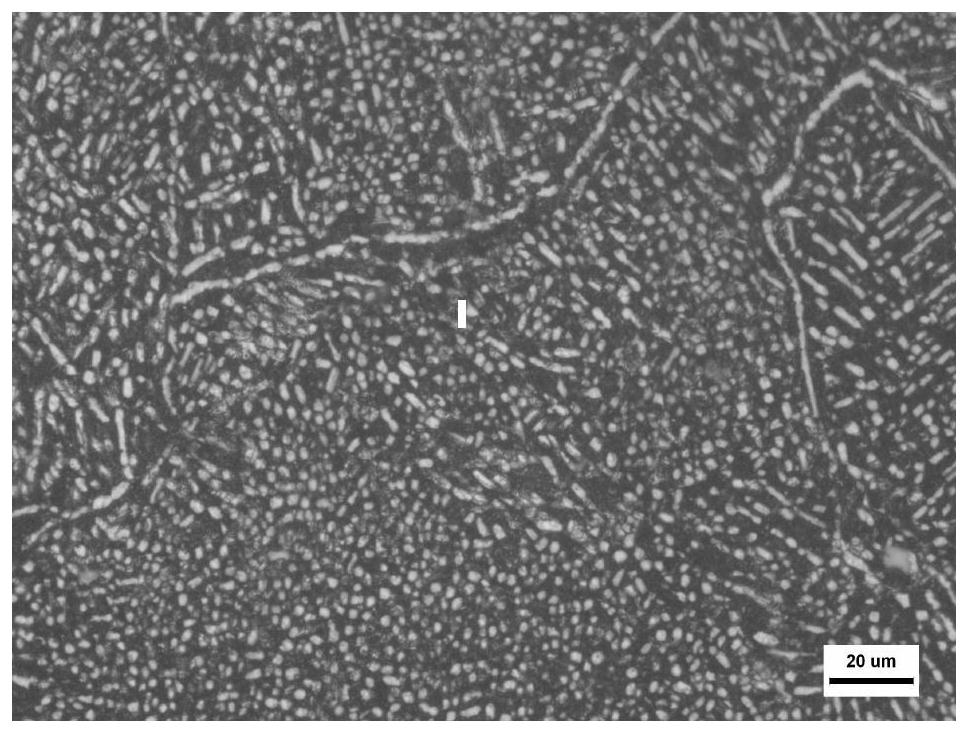

Image

Examples

Embodiment 1

[0050] The selected ingot specification is Ф720mm, the phase transition point of the ingot is 865°C, and the unit weight of the blank is 4650kg. According to the technical requirements of the product, the composition of the ingot used in the present invention is shown in Table 1:

[0051] Table 1

[0052] Ti Al Mo V Cr Fe standard requirement 4.4-5.7 4.0-5.5 4.0-5.5 0.5-1.5 0.5-1.5 base 5.30 5.0 4.9 1.0 1.1

[0053] The ingot is heated, the heating temperature is 1150°C, the heating time is 470min~570min, the radial elongation forging is carried out, and the RF100 20MN precision forging machine is used for forging. The deformation process of each pass is as follows: Φ690→Φ610→Φ550→Φ510→Φ470→Φ430 →Φ390→Φ350, cooling in the air after forging, sawing and cutting into three parts.

[0054] The heating temperature is 835°C, the heating time is 230min-280min, and the radial elongation forging is carried out. The equipment adopts RF100 type 2...

Embodiment 2

[0062] The specification of the ingot is Ф720mm, the phase transition point of the ingot is 870°C, and the unit weight of the blank is 4700kg. The chemical composition of the ingot of the present invention is shown in Table 3:

[0063] table 3

[0064]

[0065]

[0066] The heating temperature is 1150°C, the heating time is 470min~570min, the radial elongation forging is carried out, and the RF100 type 20MN precision forging machine is used for forging. The pass deformation process is as follows: Φ690→Φ610→Φ550→Φ510→Φ470→Φ430→Φ390→Φ350 After forging, cool in the air, saw and cut into three equal parts.

[0067] Low-temperature forging, heating temperature 840°C, heating time 230min~280min, radial elongation forging, equipment adopts RF100 type 20MN precision forging machine forging, the process of pass deformation is as follows: Φ350→Φ300→Φ250→Φ200→Φ160, after forging Heat the material back into the furnace.

[0068] After the hot material is returned to the furnace, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com