Preparation method of hard alloy mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

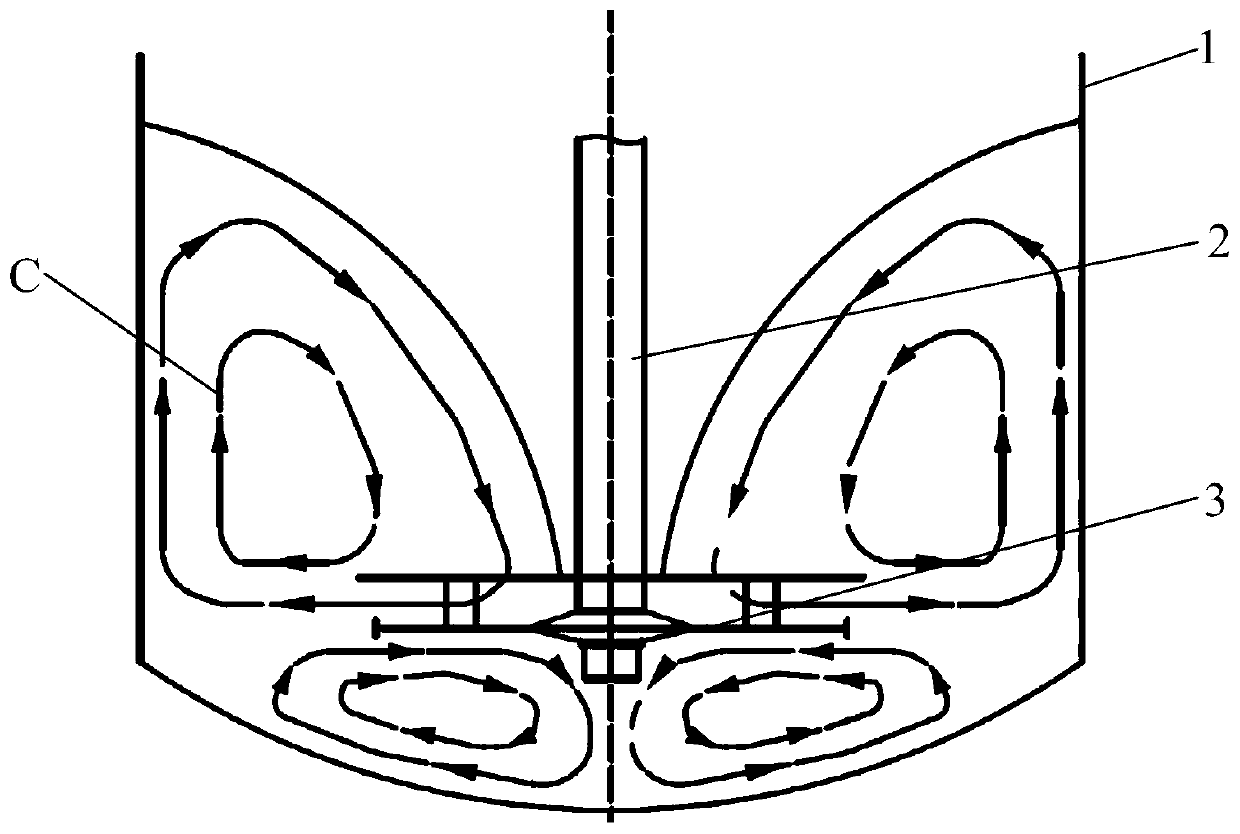

Method used

Image

Examples

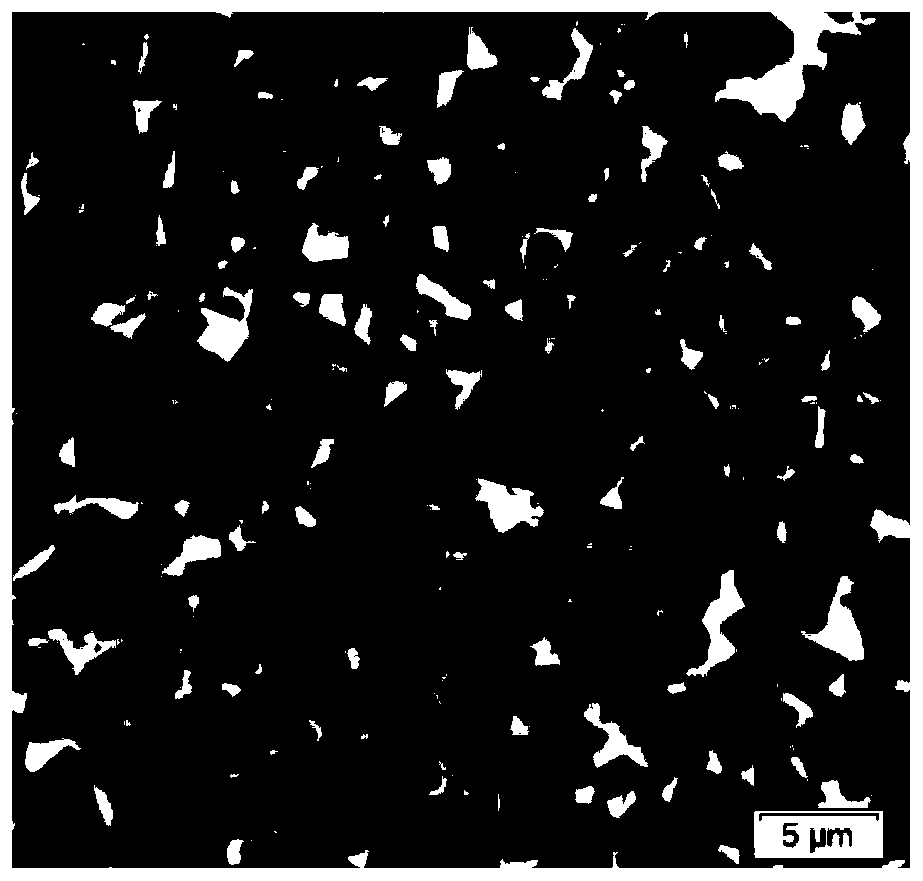

Embodiment 1

[0040] WC powder with a particle size of 4.5 μm and Co powder with a particle size of 1.3 μm are used to mix the powder according to the weight ratio WC:Co=90:10, and the dispersion medium is alcohol, which is added at a rate of 350ml per kilogram of powder, and 2.5% ( weight ratio) of emulsified paraffin wax, add 0.01% sorbitan monostearate by powder weight ratio, add Carboresin by 0.5% powder weight ratio, to improve the viscosity of slurry, dispersion cylinder airtight, Fill with nitrogen to prevent the air from entering, the speed of the dispersion disc is 2000rpm, after 6 hours of high-speed dispersion, the powder is dried at a temperature of 100°C, pressed into shape, and sintered at 1390°C for 60 minutes in a low-pressure sintering furnace integrating the release agent and sintering .

Embodiment 2

[0042] WC powder with a particle size of 0.5 μm and Co powder with a particle size of 0.8 μm are used, and the powder is mixed according to the weight ratio WC:Co=88:12. The dispersion medium is water, and the ratio of 200ml per kilogram of powder is added, and 2% ( weight ratio) of PEG, add 1% sorbitan monostearate by powder weight ratio, add methyl cellulose by 0.5% powder weight ratio, to improve the viscosity of slurry, disperse after vacuumizing The cylinder is sealed, the rotating speed of the dispersing disc is 3000rpm. After 10 hours of high-speed dispersion, the powder is dried at a temperature of 90°C, pressed into shape, and sintered at 1450°C for 30 minutes in a low-pressure sintering furnace integrating the release agent and sintering.

Embodiment 3

[0044] WC powder with a particle size of 1.0 μm and Co powder with a particle size of 1.0 μm are used to mix the powder according to the weight ratio WC:Co=90:10, and the dispersion medium is acetone, which is added at a rate of 500ml per kilogram of powder, and 5% ( weight ratio) of emulsified paraffin wax, add 2% sorbitan monostearate by powder weight ratio, add ethyl cellulose by 2% powder weight ratio, to improve the viscosity of slurry, dispersing cylinder pumping After vacuuming, fill it with nitrogen gas and seal it. The rotating speed of the dispersion disc is 500rpm. After 15 hours of high-speed dispersion, the powder is dried at a temperature of 100°C, pressed and formed, and sintered at 1360°C for 90 minutes in a low-pressure sintering furnace integrating the release agent and sintering. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com