Method for preparing metal layered composite material through high-energy pulse current assisted ultrasonic consolidation

A technology of ultrasonic consolidation and composite materials, applied in non-electric welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of excessive influence of processing technology, long preheating and cooling time, local stress residual, etc., to achieve consolidation Good quality, excellent interface mechanical properties, sufficient effect of interface metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a novel preparation method capable of rapidly preparing layered composite materials at room temperature, so as to solve the problem of long preheating and cooling times, complicated processing procedures, and poor environmental conditions when using traditional substrate heating methods to ultrasonically consolidate metal layered composite materials. The processing technology has too much influence, and temperature changes cause local stress residuals.

[0033] In order to improve the processing capability of the ultrasonic consolidation manufacturing technology and broaden its scope of application, so that it can be applied to the consolidation and forming of metal foils with higher strength and thickness, the present invention proposes the use of pulse Current-assisted synchronously coupled ultrasonic consolidation manufacturing new technology for preparing metal layered composites. That is, using the electroplastic effect of the pulse curr...

Embodiment 1

[0041] Take Ti foil and Al foil with a thickness of 0.2mm, use alcohol to remove dirt and grease on the surface, and then dry for later use. Take the "Ti foil-Al foil" combination as a consolidation unit, in which the Ti foil is on the top and the Al foil is on the bottom. A total of 5 consolidation units are prepared.

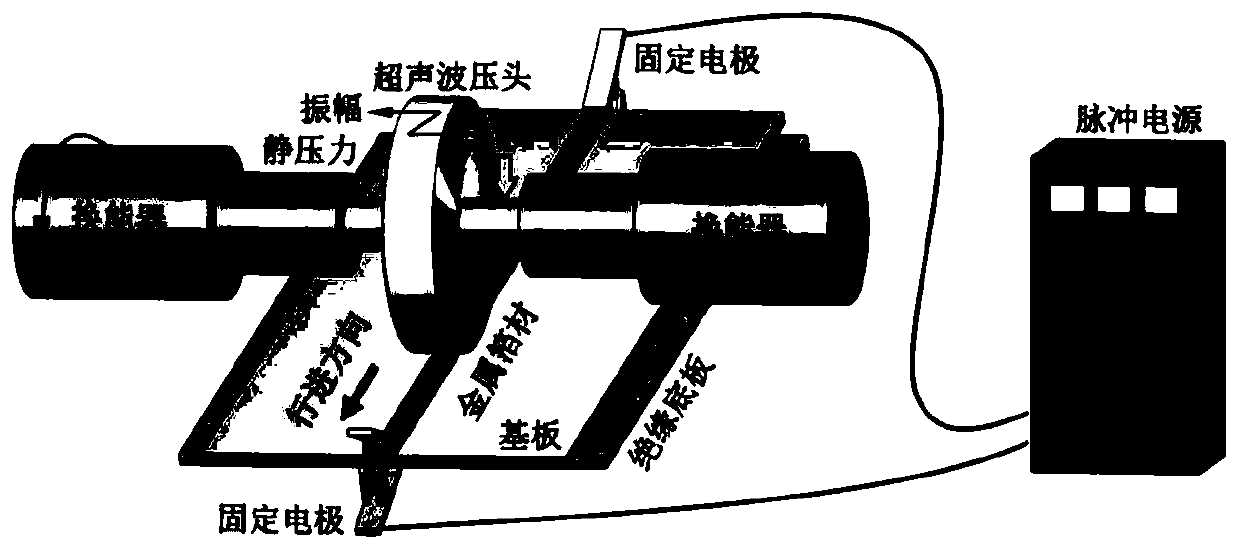

[0042] In the preparation of pulse current-assisted ultrasonic consolidation of titanium-aluminum laminated composite materials, the specific process parameters are: ultrasonic amplitude of 40μm, static pressure of 2000N, consolidation speed of 25mm / s, pulse current density of 1.35A / mm2, pulse current frequency 150Hz, see attached diagram for the prepared device figure 1 . The above parameters are used to complete the consolidation of the first pass of the foil unit, and the process parameters are repeated to prepare a titanium-aluminum layered composite with a total of five consolidation units.

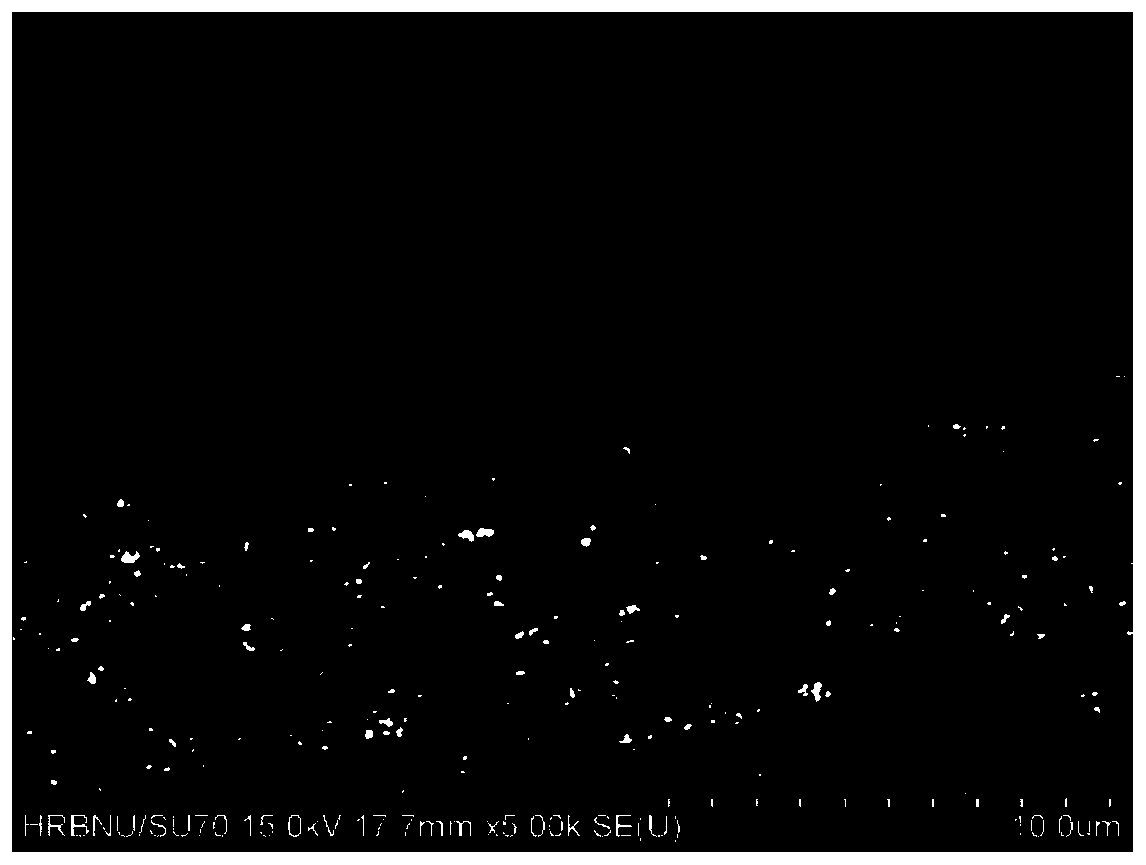

[0043] The cross-sectional micrograph of the titanium-aluminum laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com