Coaxial self-adaptive electric drive assembly adopting central drive mode

A central drive, coaxial technology, used in bicycles, motor vehicles, power units, etc., can solve the problems of motor stall, the weight of the speed change mechanism and the motor, and the heat generation, and achieve the best heat dissipation capacity and high mechanical efficiency. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

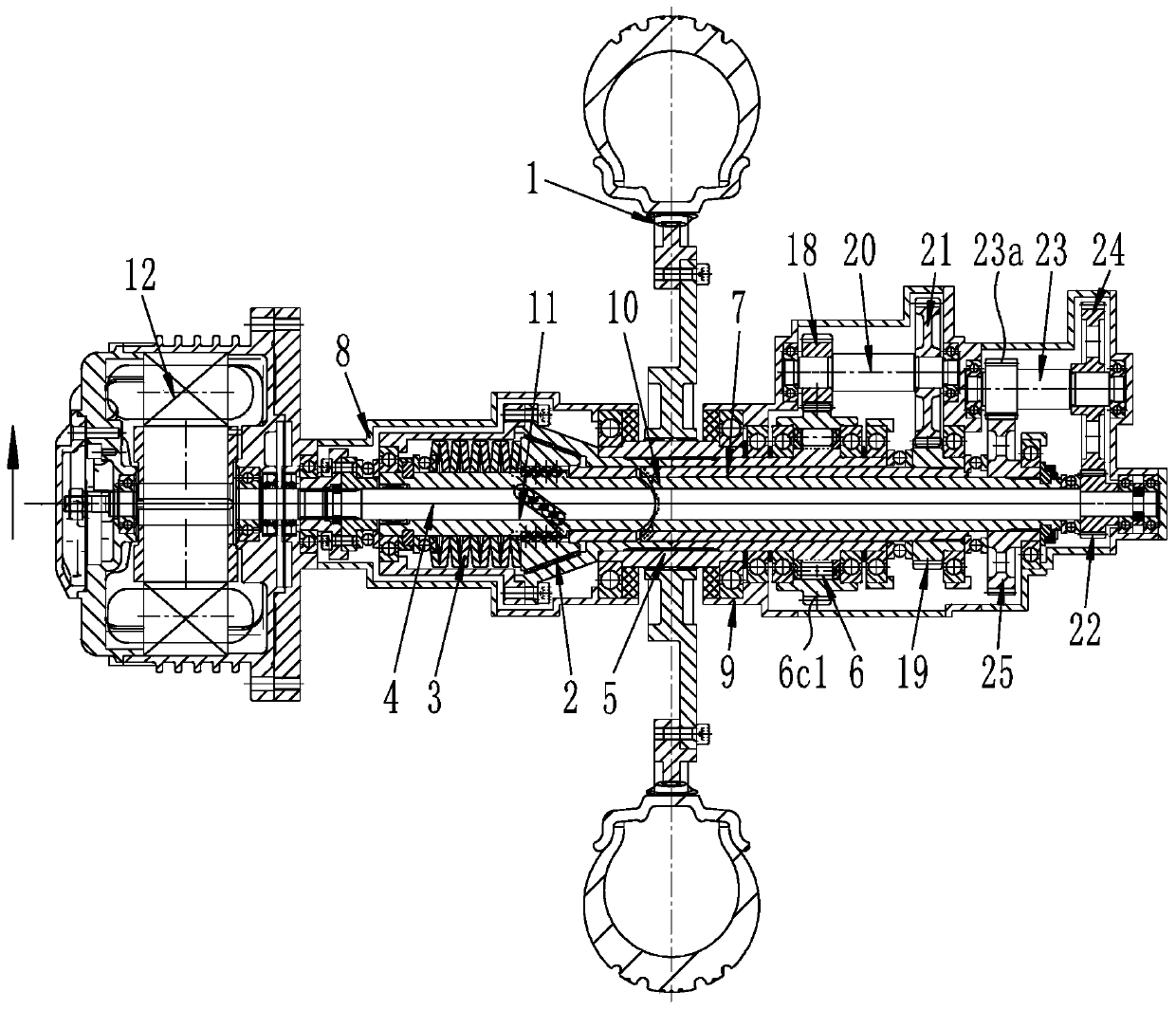

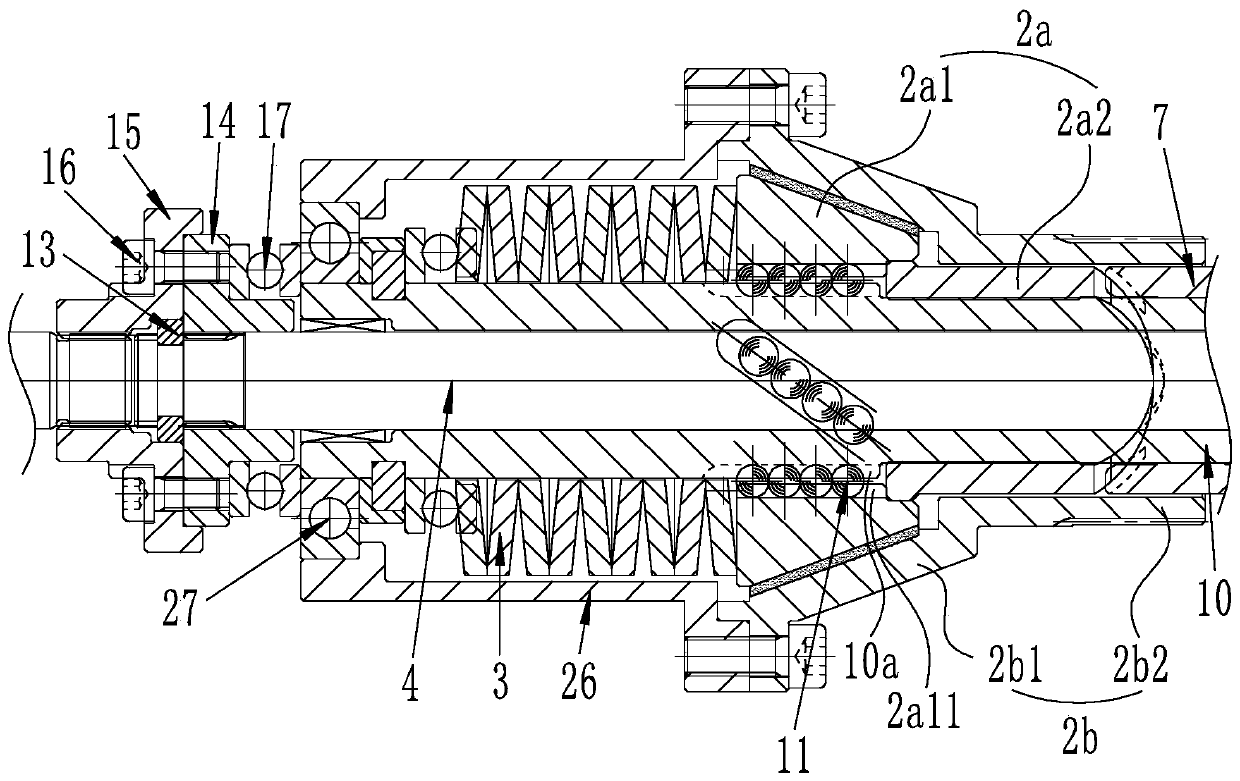

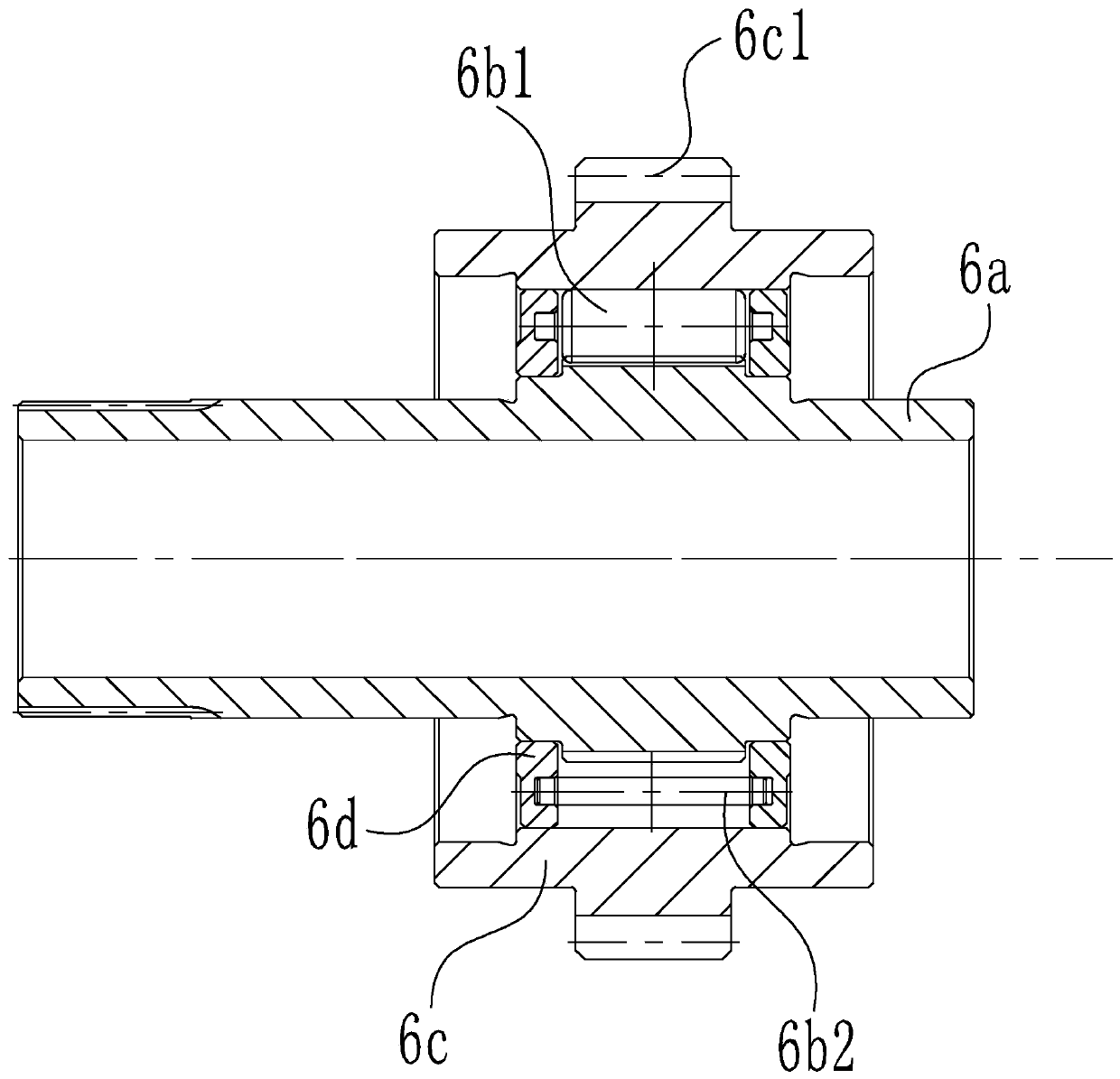

[0037] Such as figure 1 As shown, a coaxial self-adaptive electric drive assembly in the form of a central drive mainly includes a rotating output component 1, a motor 12 and a transmission system, and the motor 12 drives the output component 1 through the transmission system. Both sides of the rotary output member 1 are respectively provided with a first box body 8 and a second box body 9, and the transmission system includes a power input mechanism, a high-speed gear transmission mechanism, a low-speed gear transmission mechanism and a main shaft 4, and the main shaft 4 can be The main drive sleeve 10 is rotatably fitted, the power input mechanism and the high-speed transmission mechanism are installed in the first case 8, the low-speed transmission mechanism and the power input mechanism are installed in the second case 9, and the main shaft 4 and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com