Lens packaging device

A lens and clamping technology, applied in packaging and other directions, can solve problems such as lens surface damage, achieve the effects of reducing labor costs, improving product yield, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

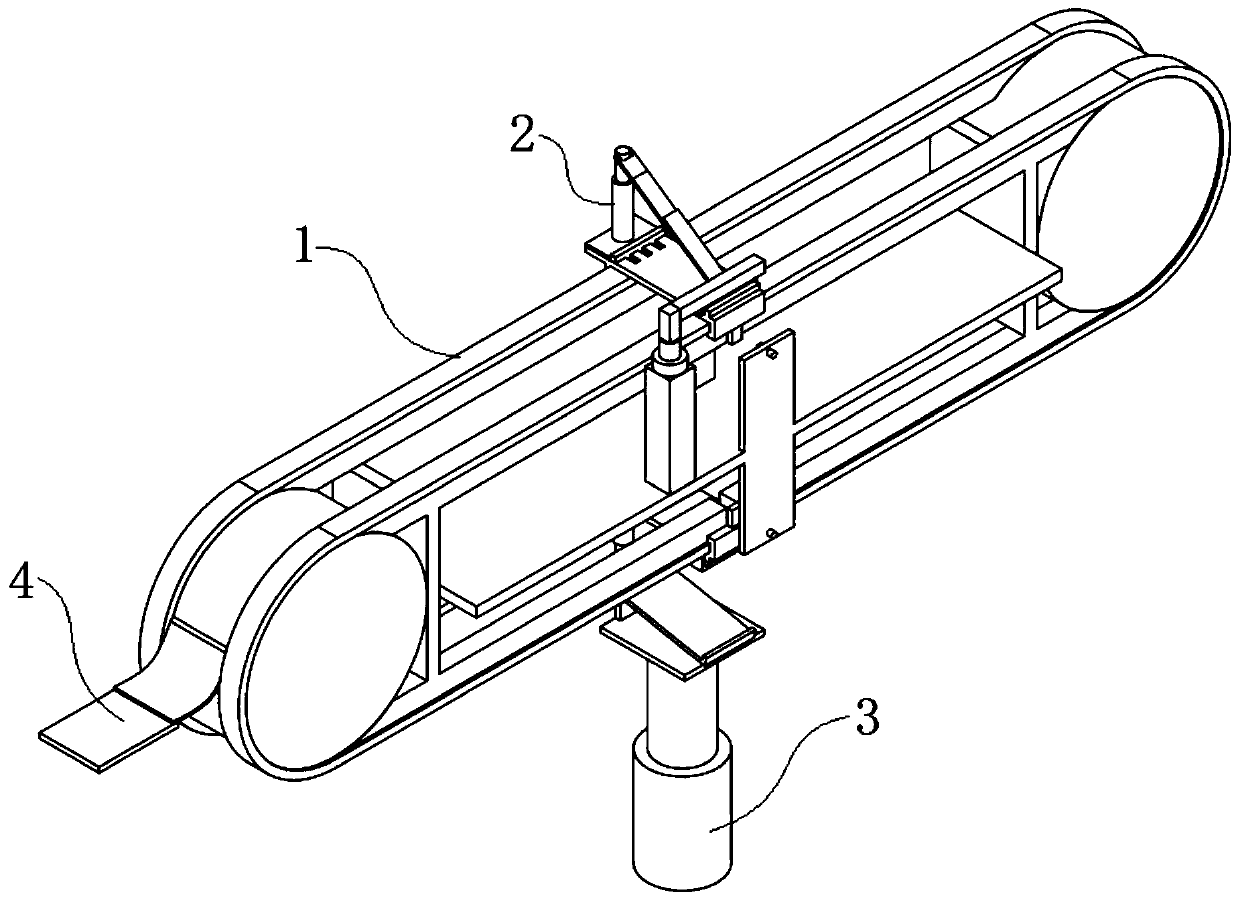

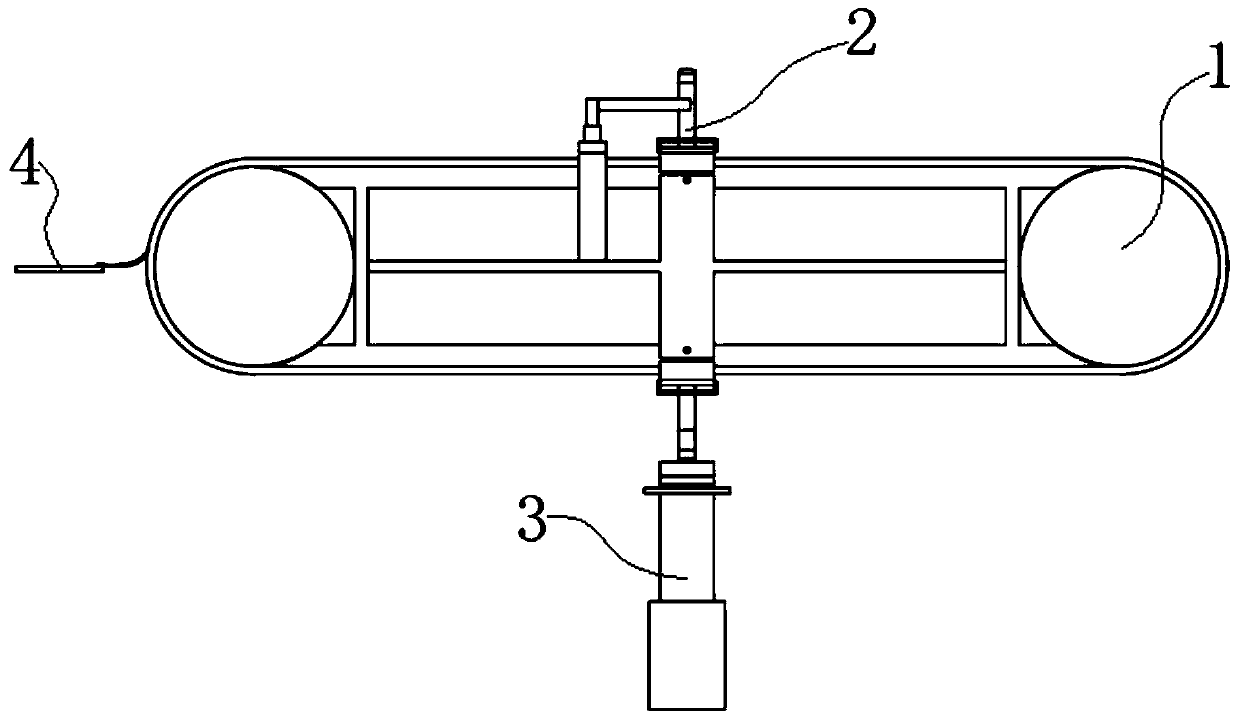

[0033] see Figure 1-2 As shown, the present invention is a lens packaging device, including a rotating frame 1, a clamping seat 2, a loading arm 3 and a material guide plate 4, a number of clamping seats 2 are connected and matched with the rotating frame 1, and the loading arm 3 is connected to the clamping The seats 2 cooperate with each other, the material guide plate 4 is arranged on one side of the rotary frame 1, and the material guide plate 4 and the clamping seat 2 cooperate with each other.

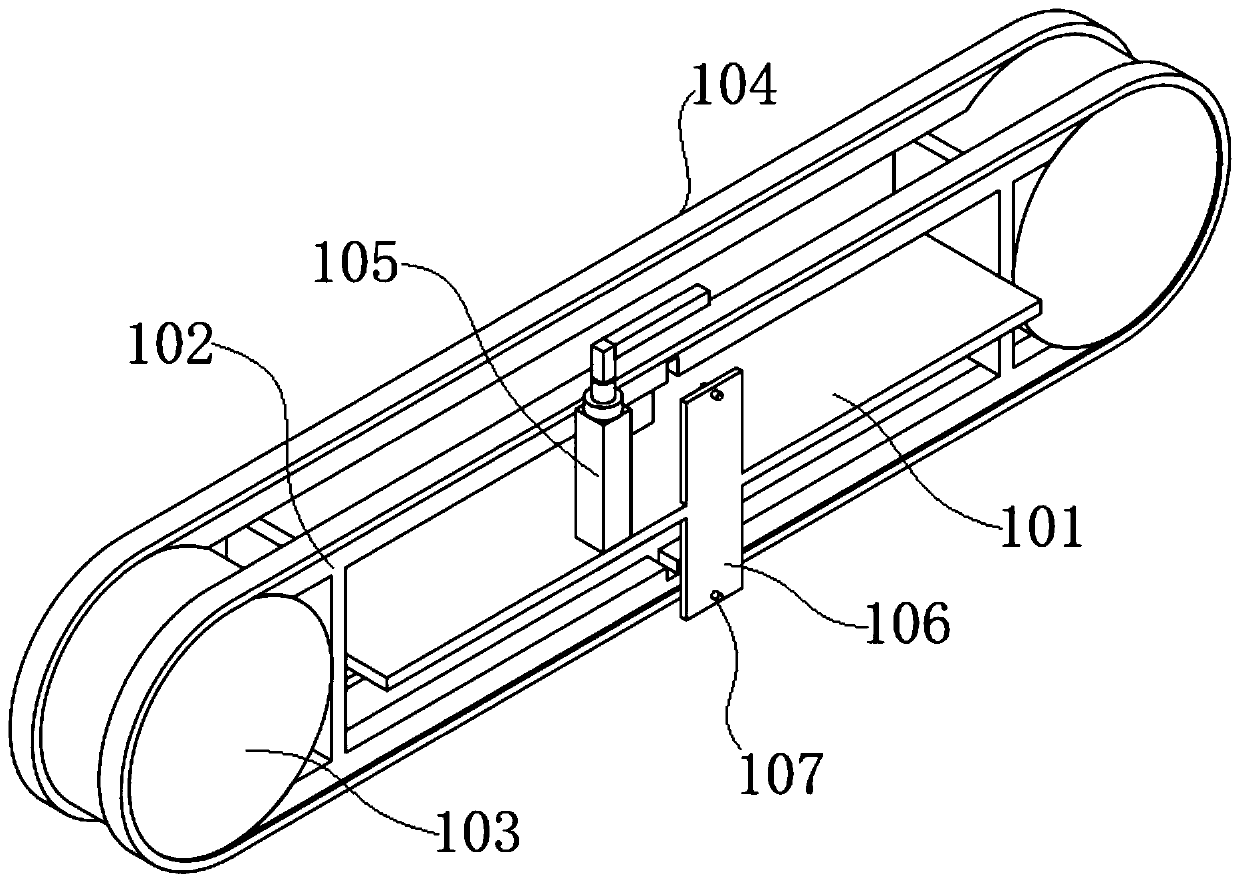

[0034] like Figure 3-5 As shown, the rotating frame 1 includes a fixed plate 101, a fixed frame 102, a driving wheel 103, a conveyor belt 104, a material retrieving platform 105, a positioning plate 106 and a photoelectric sensor 107, and the fixed plate 101 is arranged in the fixed frame 102. One surface of the fixed plate 101 is Connected with the reclaiming platform 105, the opposite sides of the fixed frame 102 are equipped with driving wheels 103, the sides of the fixed f...

Embodiment 2

[0043] see Figure 1-9 As shown, the present invention is a lens packaging device. Its working principle and usage method are as follows: several clamping seats 2 are evenly installed on the conveyor belt 104 of the rotating frame 1. Preferably, two surfaces of the clamping seats 2 are oppositely arranged The distance between the two pallets 202 is greater than the width of the driving wheel 103, and the surface of the conveyor belt 104 is provided with some limiting holes, the limiting holes and the clamping plates 202 are connected by pins, and the packaging box is a plastic box with a rotating cover;

[0044] When in use, when the clamping seat 2 moves to a designated position, the mask sheet 210 on the clamping seat 2 covers the photoelectric sensor 107, the clamping seat 2 stops, and the main lifting arm on the loading arm 3 rises at the same time, and the packaging One side of the box is in contact with the sliding baffle 204, and then the push rod is stretched to lift u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com