Non-uniform-velocity falling-type synchronous taking-up device for producing Dumet wires

A wire take-up device and drop-type technology, which is used in transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc. Line quality, reduce speed fluctuations, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

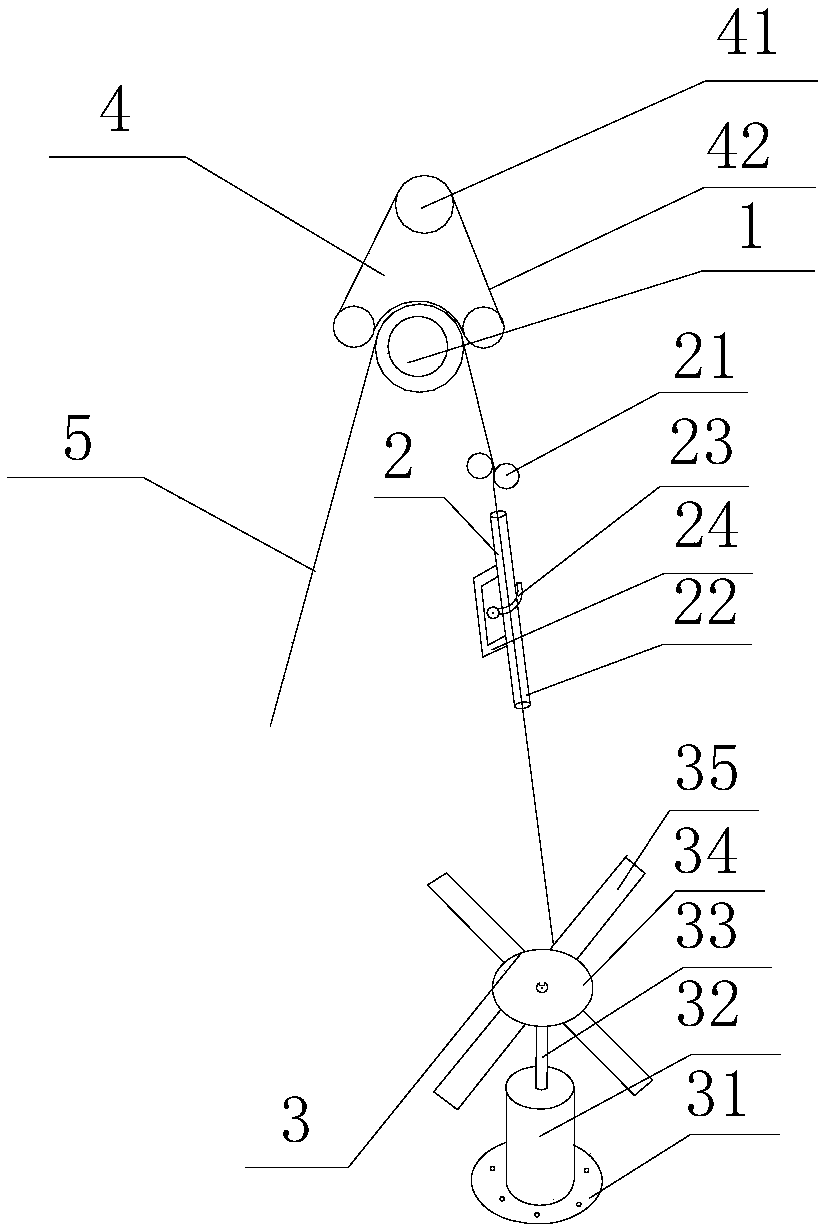

[0014] Embodiment: a non-uniform-speed drop-type synchronous take-up device for producing Dumet silk, including a synchronous fixed-speed take-up wheel 1, a guide straightening assembly 2, a drop-type synchronous take-up barrel 3 and a PLC intelligent control system, Controlled by the PLC intelligent control system, the wire 5 is guided into the guide straightening assembly 2 by the synchronous fixed-speed take-up wheel 1, and the straightened wire is collected into the drop-type synchronous take-up barrel 3.

[0015] The synchronous fixed speed take-up reel 1 is also equipped with a rotary pressure damping device 4, the rotary pressure damping device 4 is located directly above the synchronous fixed speed take-up reel 1, and the rotary pressure damping device 4 includes a set of The rotating shaft is arranged in an isosceles triangle, and the roller 41 is sleeved on the rotating shaft, and the transmission belt 42 is sleeved on the roller 41. The bottom belt section of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com