Low-molecular-weight polyolefin emulsion applied to seed coating agent film-forming agent and preparation method of low-molecular-weight polyolefin emulsion

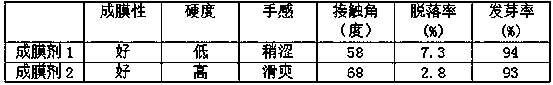

A low-molecular-weight polyethylene and low-molecular-weight technology, which is applied in the field of low-molecular-weight polyolefin emulsion and its preparation, can solve the problems of sticky film, low hardness of coating film, adhesion and agglomeration between coating films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A low-molecular-weight polyolefin emulsion applied to a seed coating film-forming agent is prepared from the following raw materials in parts by weight:

[0032] Low molecular weight polyethylene AC540 (Honeywell) 15 parts

[0033] Low molecular weight polyethylene AC-6 (Honeywell) 15 parts

[0034] Span 60 (commercially available) 1.0 parts

[0035] Tween 60 (commercially available) 1.5 parts

[0036] 12 sodium alkyl sulfates 1.5 parts

[0037] 16-18 alcohol (commercially available) 2 parts

[0038] Wetting agent Wet240 (Digo Company) 1 part

[0039] Preservative BM-6 (commercially available) 0.2 parts

[0040] 67 parts of water

[0041] The preparation method of the above-mentioned low-molecular-weight polyolefin emulsion applied to the film-forming agent of the seed coating agent comprises the following steps: 15 parts by weight of low-molecular-weight polyethylene AC540, 15 parts by weight of low-molecular-weight polyethylene AC-6, 1 part by weight of Add Spa...

Embodiment 2

[0043] A low-molecular-weight polyolefin emulsion applied to a seed coating film-forming agent is prepared from the following raw materials in parts by weight:

[0044] Low molecular weight polypropylene AC907 (Honeywell) 40 parts

[0045] Isomerized 10 alcohol ether (12EO) 4 parts

[0046] Sodium 12 alkylbenzene sulfonate 1 part

[0047] 2 parts stearic acid

[0048] Wetting agent Wet240 (Digo Company) 1.5 parts

[0049] Preservative BM-6 (commercially available) 0.2 parts

[0050] 73 parts of water

[0051]The preparation method of the above-mentioned low-molecular-weight polyolefin emulsion applied to the film-forming agent of the seed coating agent comprises the following steps: sequentially adding 40 parts by weight of low-molecular-weight polypropylene AC907, 4 parts by weight of isomerized 10 alcohol ether, 1 part by weight of 12 Add sodium alkylbenzene sulfonate, 2 parts by weight of stearic acid and 1.5 parts by weight of wetting agent Wet240 into the pressure em...

Embodiment 3

[0053] A low-molecular-weight polyolefin emulsion applied to a seed coating film-forming agent is prepared from the following raw materials in parts by weight:

[0054] Low molecular weight polyethylene AC330 (Honeywell) 30 parts

[0055] Isomerized 10 alcohol ether (12EO) 3 parts

[0056] 12 Sodium Alkyl Sulfate 1 part

[0057] 16-18 alcohol (commercially available) 1 part

[0058] Wetting agent Wet240 (Digo Company) 2 parts

[0059] Preservative BM-6 (commercially available) 0.1 parts

[0060] 70 parts of water

[0061] A preparation method for a low molecular weight polyolefin emulsion applied to a seed coating film forming agent, comprising the following steps: 30 parts by weight of low molecular weight polyethylene AC330, 3 parts by weight of isomerized 10 alcohol ether, 1 part by weight of 12 Sodium alkyl sulfate, 1 part by weight of 16-18 alcohol and 2 parts by weight of wetting agent Wet240 are added to the pressure emulsification tank, heated to 160 ° C, melted u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com