A kind of cnts reinforced magnesium-based composite material and preparation method thereof

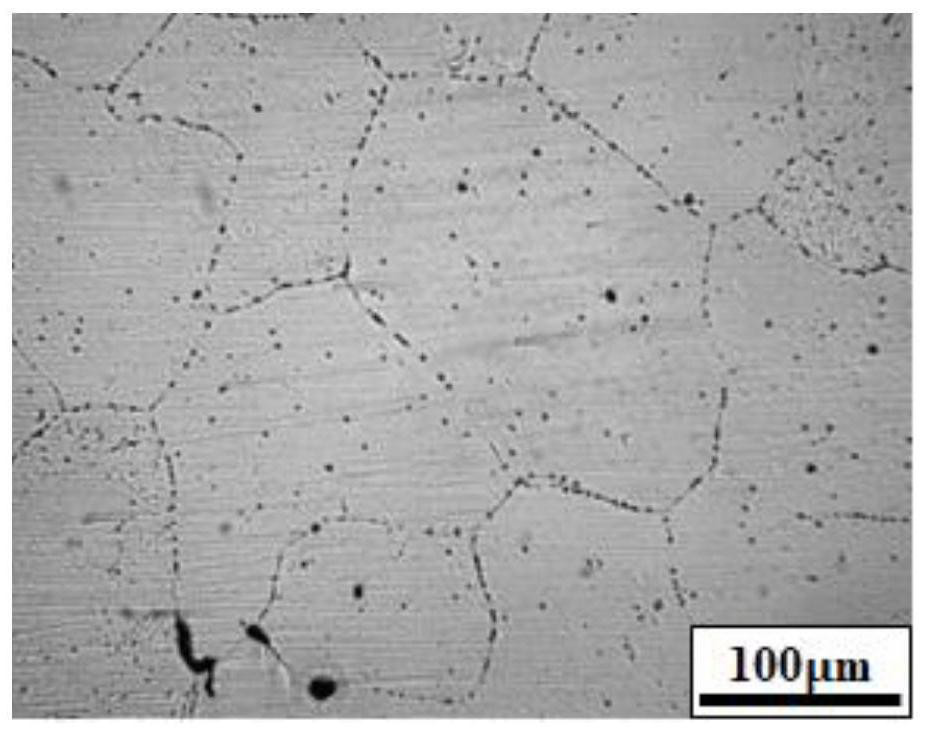

A technology of composite materials and magnesium ingots is applied in the field of preparation of magnesium-based composite materials, which can solve the problems of limited development and reduced elongation, and achieve the effects of strict procedures, improved strength, and significantly finer grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0030] The preparation process of CNTs / Mg-6Zn composite material of the present invention is as follows:

[0031] S1, Pretreatment of CNTs

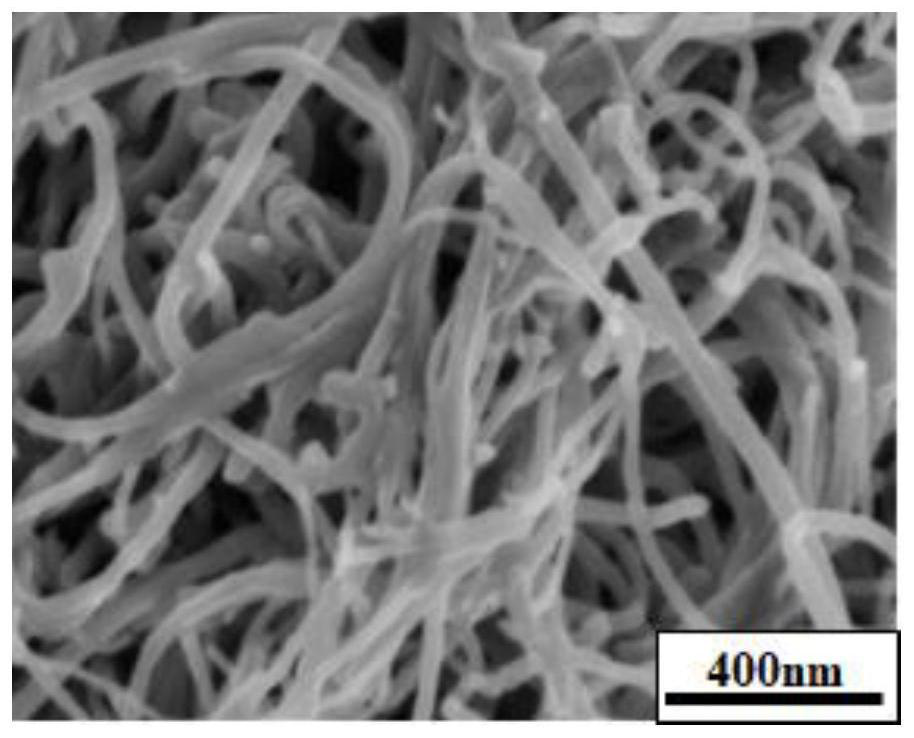

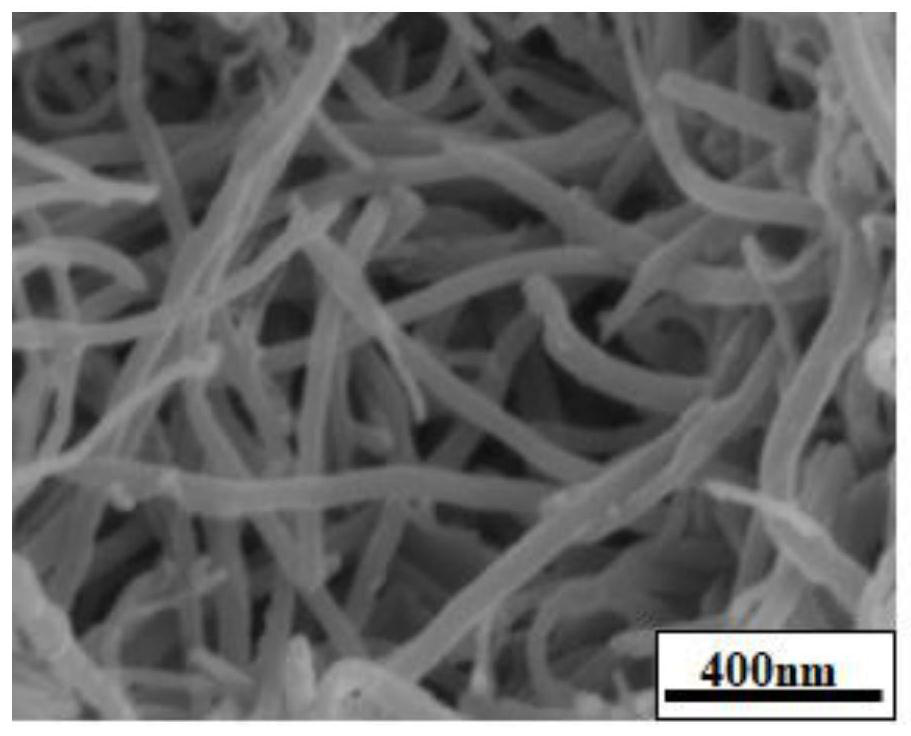

[0032] Carbon nanotubes (CNTs) have strong van der Waals forces and relatively large areas, so pristine CNTs generally exist in the form of winding and agglomeration. The present invention purifies CNTs (concentrated sulfuric acid and concentrated nitric acid mixed acid solution with a volume ratio of three to one), which can effectively remove amorphous carbon and impurities therein; the present invention weighs 6g of original CNTs;

[0033] CNTs will be lost after pretreatment, and the loss ratio is about 25%. The present invention weighs 0.5vol% of CNTs after pickling, and the weighing amount is 4.08g;

[0034] S2, preparing magnesium alloy semi-solid slurry:

[0035] First, raise the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com