Deep brine exploration and extraction combination technology

A kind of brine and deep layer technology, applied in the field of deep brine exploration and production combined technology, can solve the problems of complex ore-hosting strata, difficulty in realizing layered evaluation of brine resources, and waste of well hole resources, so as to improve the efficiency of drilling wells and avoid mutual mixed pollution , Reduce the effect of inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

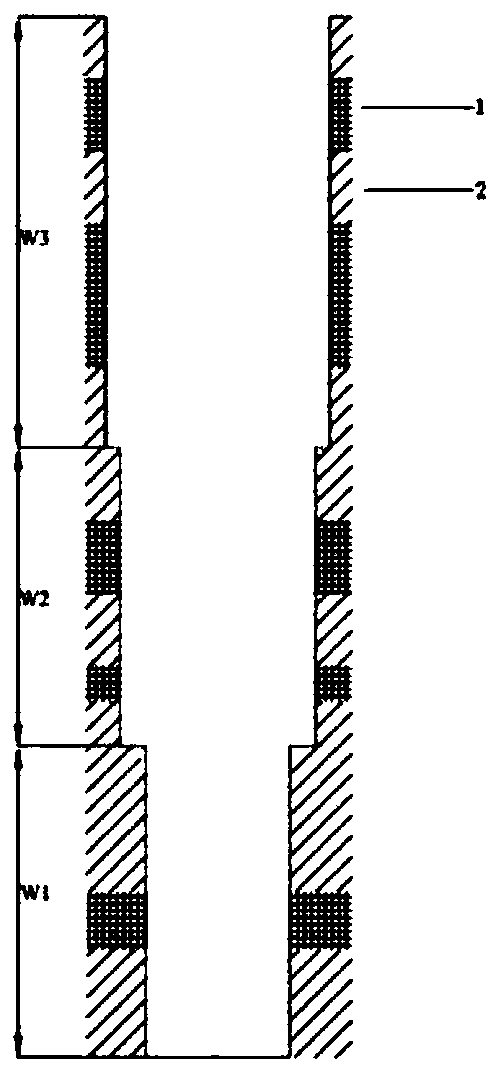

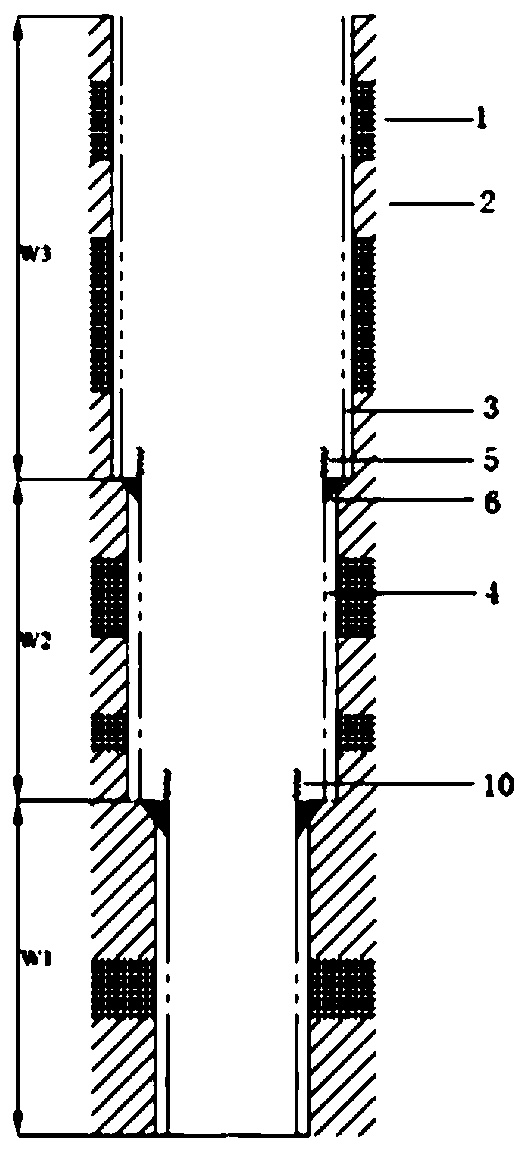

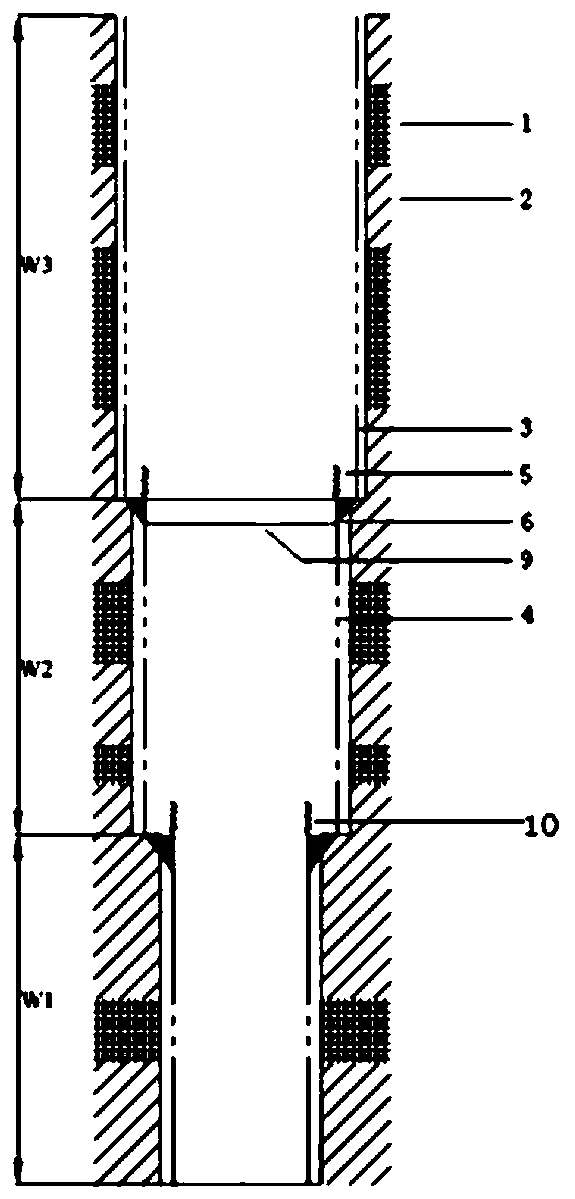

[0029] Such as Figure 1-6 As shown, the present invention is a combination process of exploration and production of deep brine, comprising the following steps.

[0030] (1) Drilling steps

[0031] The core is taken from the whole hole with a hole diameter of 216mm to the bottom. During the coring process, mud with a specific gravity of 1.65 is used to protect the wall and suppress the high-pressure water gushing layer, so that the well wall is stable and the mud circulates normally.

[0032] (2) Measuring steps

[0033] After coring and drilling to the final hole, full-hole logging is carried out to measure relevant indicators.

[0034] (3) Reaming step.

[0035] After the logging is completed, the divisional depth positions of each aquifer section are determined through comprehensive analysis of core records, well logging, and geological profile data, and then reaming is performed with reaming bits of different apertures according to the divided depths of each aquifer sec...

Embodiment 2

[0063] In Example 1, the W 1 Water section, W 2 Water section, W 3 The reaming diameters of the water-containing sections were changed to 152mm, 216mm, and 311mm, respectively, and the casing diameters were changed to 127mm, 168mm, and 245mm, respectively. The same as in Example 1 except that. The well-formed well diameter and pipe matching table of embodiment 1 and embodiment 2 are shown in table 1.

[0064] Table 1

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com