A Calculation Method for Liquid Volume in Tank of Ballast Monitoring System of Floating Offshore Platform

A floating offshore platform and liquid volume technology, which is applied in the field of ballast water loading and discharge liquid level monitoring of floating offshore platforms and platform draft monitoring, can solve the problem of affecting the accuracy of platform regulation ballast, lack of monitoring draft information, Ballast numerical error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

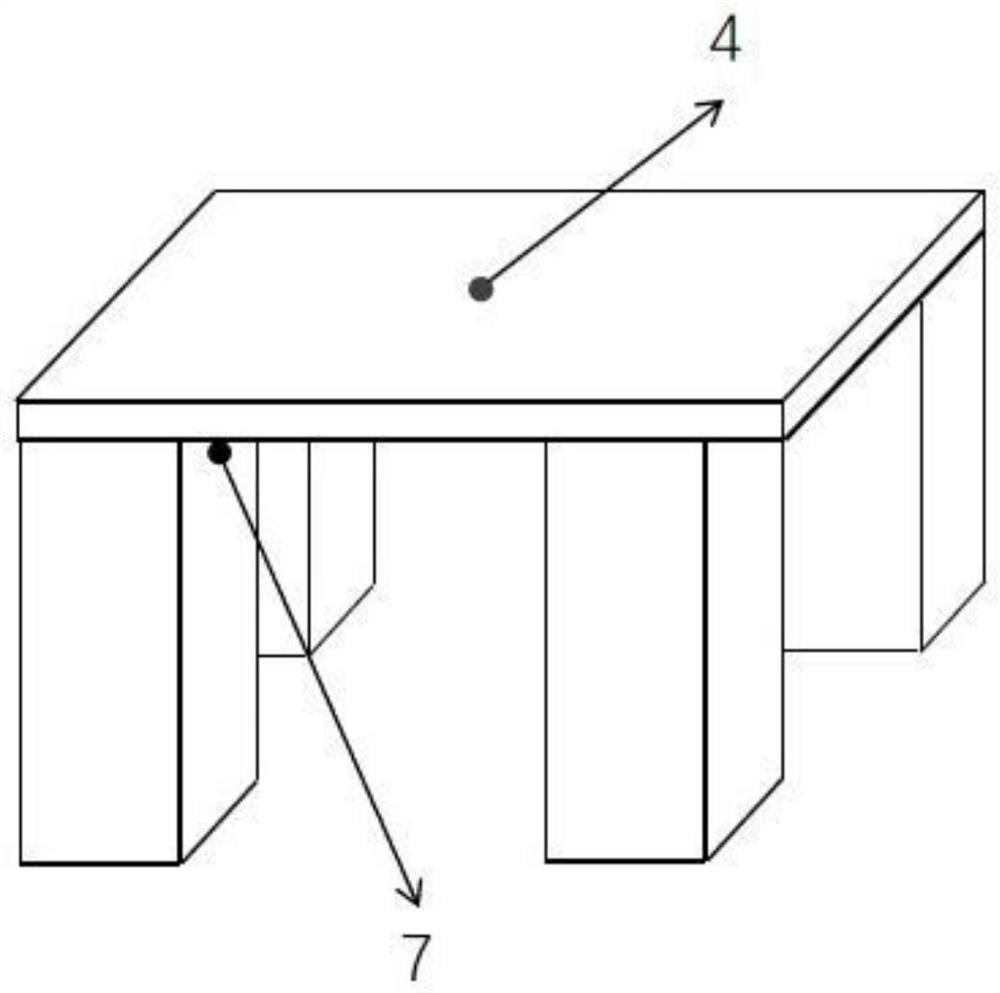

[0037] figure 1 A schematic diagram of the installation of the ultrasonic liquid level gauge and the dual-axis inclination sensor is shown. In the figure, the ultrasonic level gauge 7 is installed on the inner side of the buoy 9 under the deck, and one is installed on each buoy, four in total. The measurement direction of the ultrasonic liquid level gauge is parallel to the buoy, which is used to measure the distance between the inside of the buoy and the water surface in real time, and then convert it to obtain the draft of the platform. Its measurement frequency is fast, and 4-5 sets of data can be measured per second. The biaxial inclination sensor 4 is installed in the room close to the center of the platform to measure the overall heel angle and pitch angle of the platform in real time.

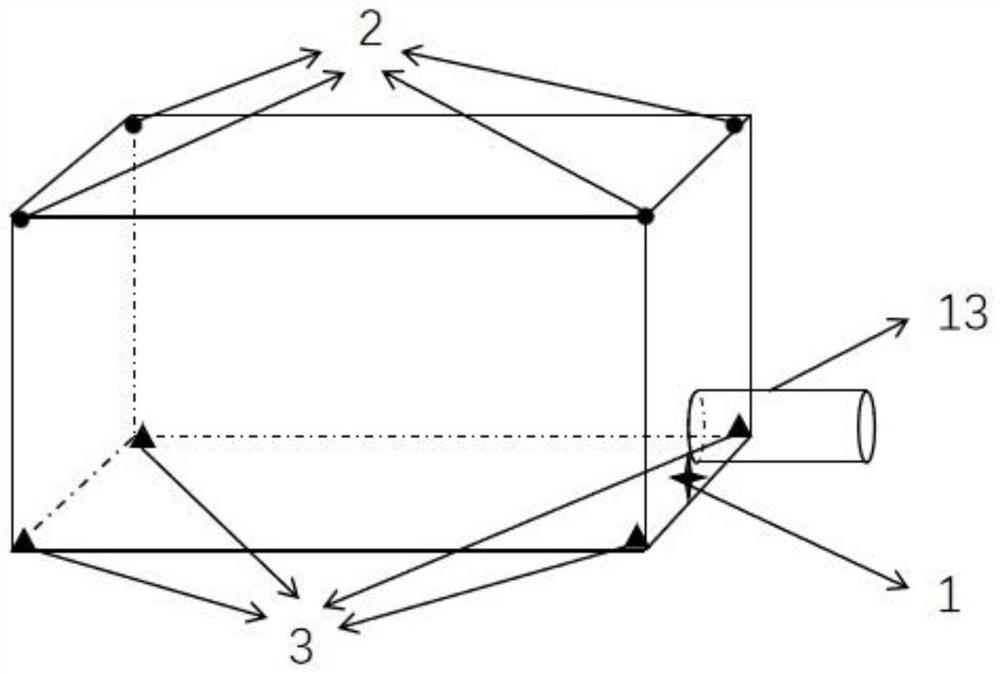

[0038] figure 2 A schematic diagram of the installation of the liquid level monitoring sensor in the tank is shown. In the figure, the liquid density meter 1 is installed at the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com