Arch-shaped self-oxygen-supply waste heat utilization type direct methanol fuel cell

A methanol fuel cell and methanol fuel technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of hindering the reaction, increasing the volume of the system, and increasing the difficulty of battery management, so as to reduce the overall cost, extended working hours, and the effect of ensuring operability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but it should be noted that the protection scope of the present invention is not limited to the scope expressed in the examples.

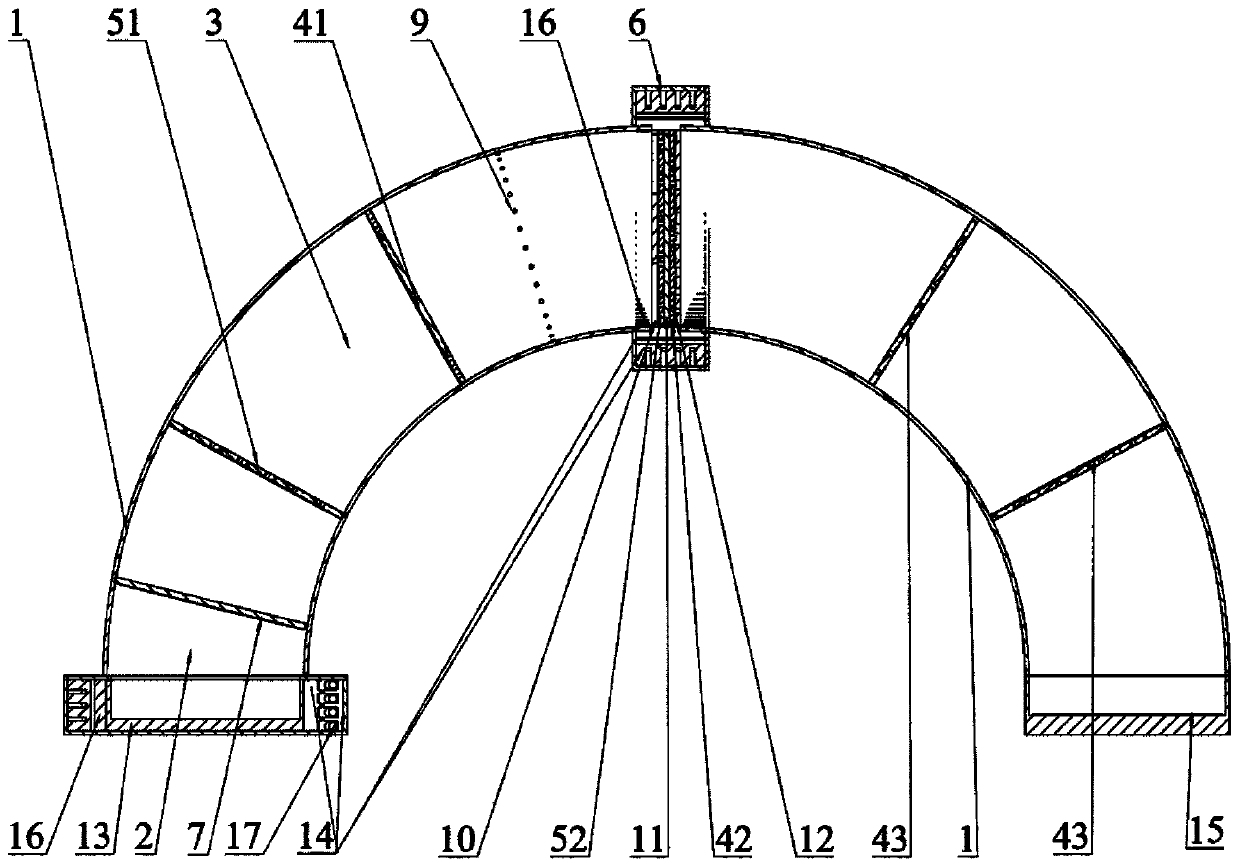

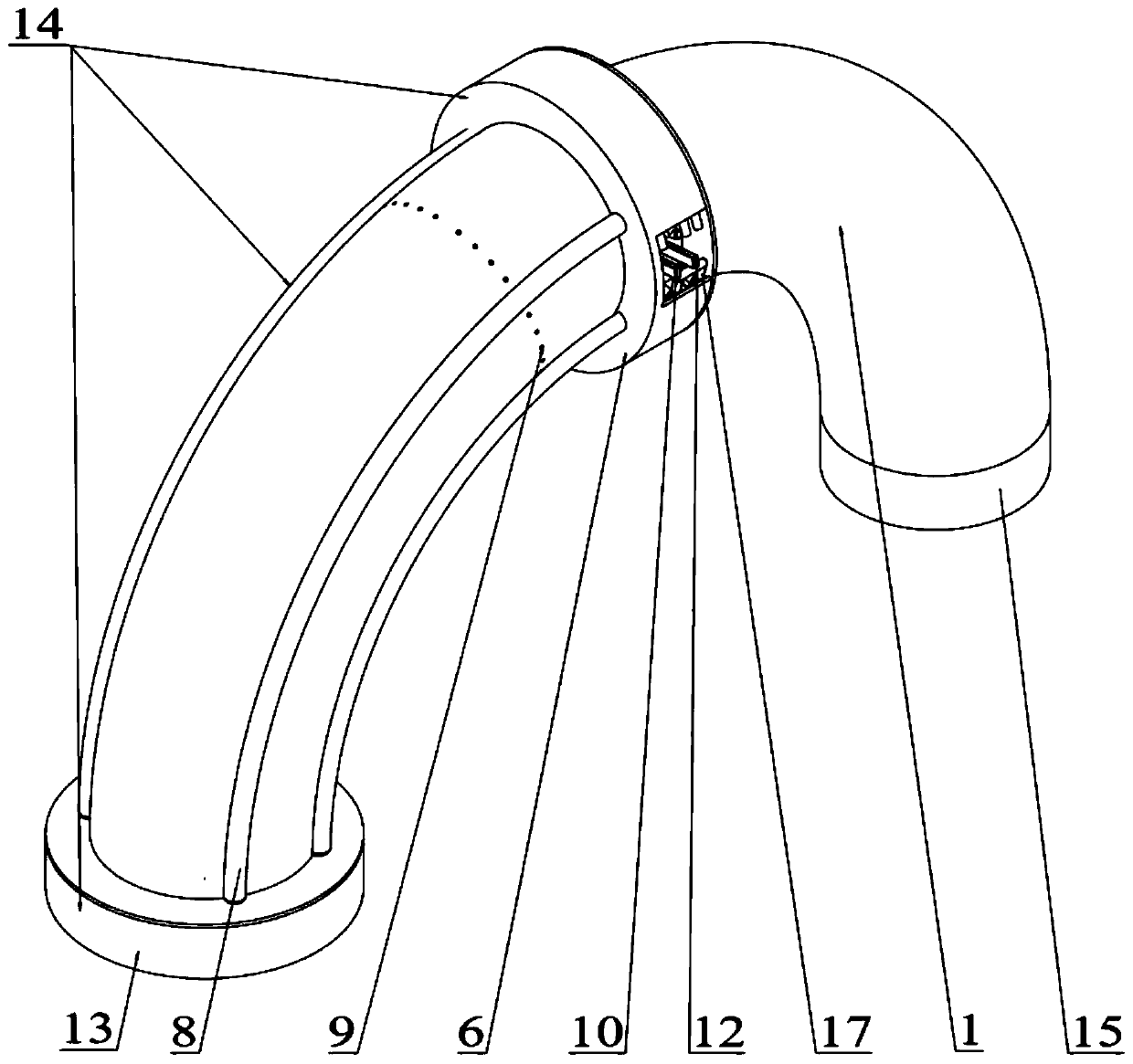

[0041] Such as figure 1 and figure 2 As shown, an arched self-supplied oxygen waste heat utilization type direct methanol fuel cell includes an arched shell 1, a pervaporation membrane 7, a central reaction part, an oxygen generation chamber 15 and a thermodynamic cycle system 14; the pervaporation membrane 7 Divide the arched shell 1 into a methanol fuel chamber 2 and a steam chamber 3;

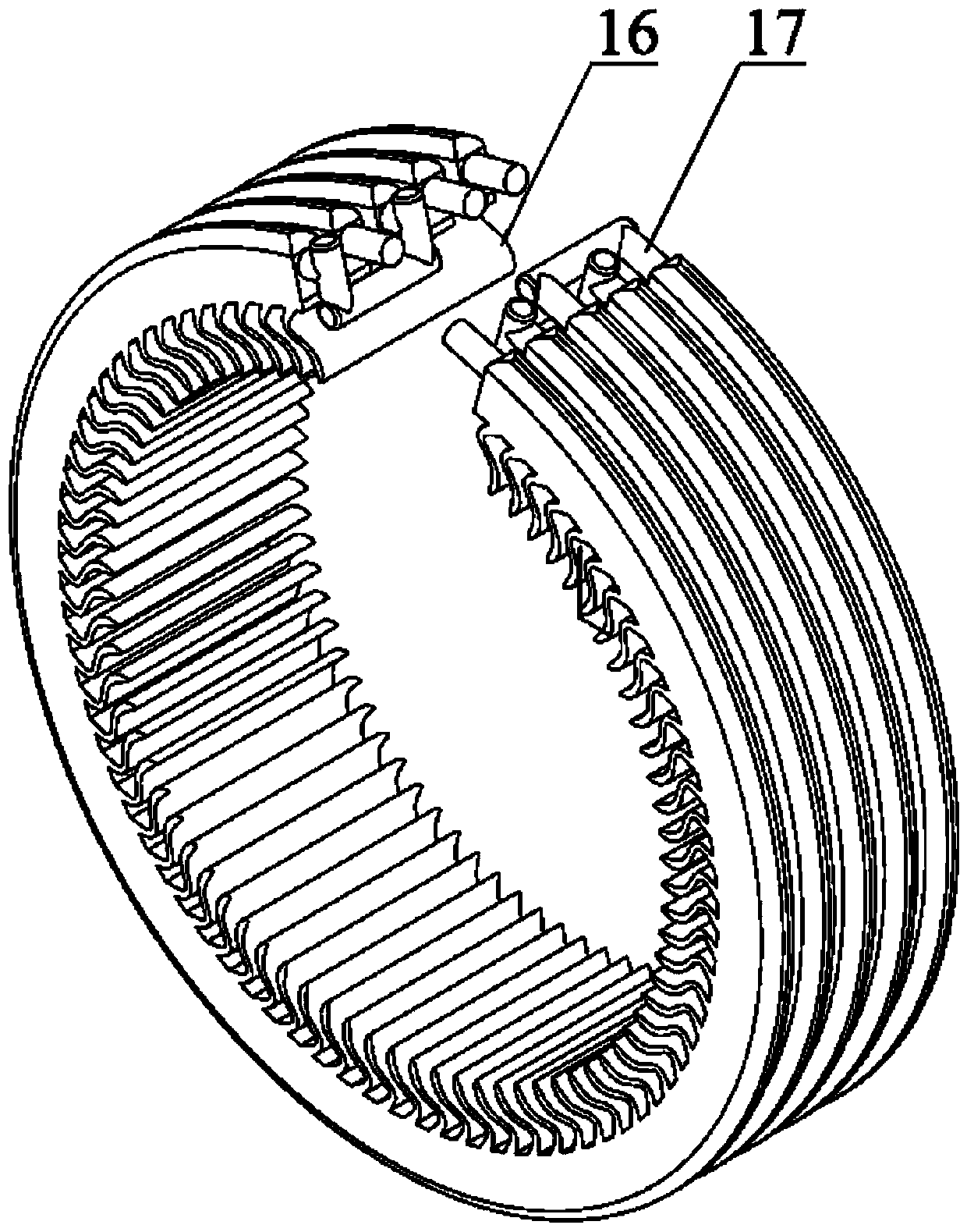

[0042] The arched housing 1 is mainly formed by connecting two quarter ring pipes made of epoxy resin, which ensures the visualization of the fuel cell reaction, and the ring pipe also ensures The basic dimensions are defined, such as methanol fuel chamber 2, pervaporation membrane 7, hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com