High-temperature long-distance sensorless direct-current brushless motor driving device

A brushless DC motor and driving device technology, which is applied in the starting device, electronic commutation motor control, electrical components, etc., can solve the problems of normal start and operation of the DC brushless motor that are not mentioned, and achieve the reduction of PWM signal feedback. The effect of the influence of electromotive force noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

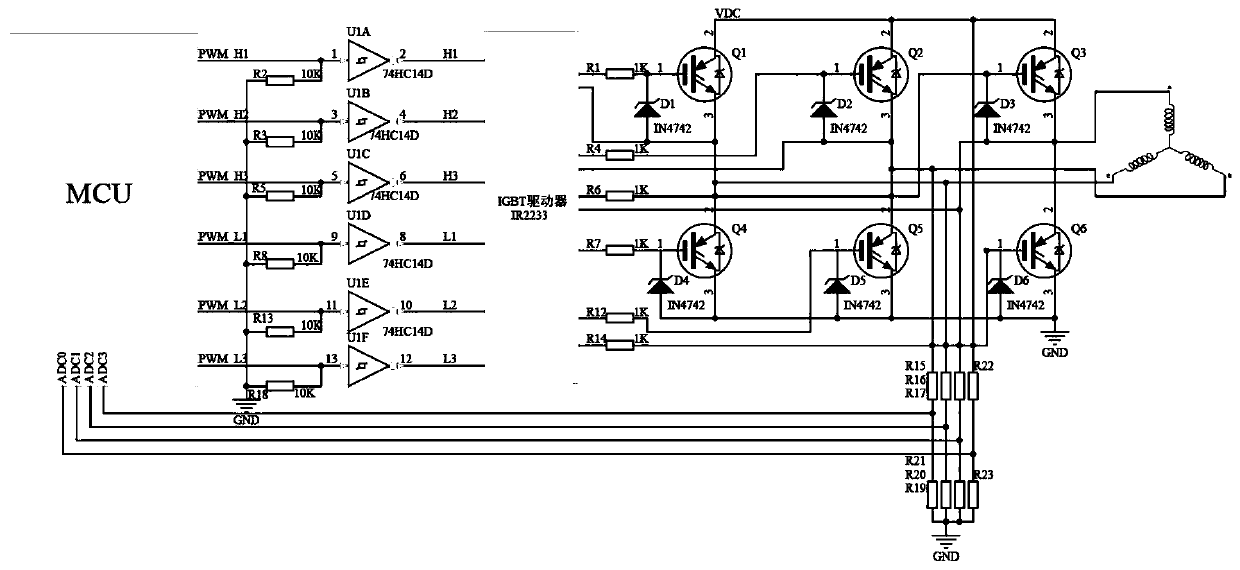

[0021] High temperature long distance position sensorless brushless DC motor drives such as figure 1 As shown, including industrial-grade 125°C high-temperature MCU (stable operation at high temperature of 150°C), 6 inverters (74HC14D), IGBT drivers (IR2233), 6 175°C junction temperature IGBTs (Q1, Q2, Q3, Q4 , Q5, Q6) and RCD absorption protection circuit. Industrial-grade 125°C high-temperature MCU can work stably in a high-temperature environment of 125°C. Available models include: sm320f28335gbs, sm320f28335ptps, etc.; 175°C junction temperature IGBT can work stably in a high-temperature environment of 175°C. Available models include: h20r1203, k75t60 etc.

[0022] Industrial-grade 125°C high-temperature MCU outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com