Electric vehicle permanent magnet synchronous motor torque control method

A permanent magnet synchronous motor and torque control technology, which is applied in motor generator control, single motor speed/torque control, electronic commutation motor control, etc., can solve the problems of not being able to keep up in time, battery voltage drop, and violation of accuracy requirements and other problems, to achieve the effect of fast response, satisfying stability, and fast torque accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

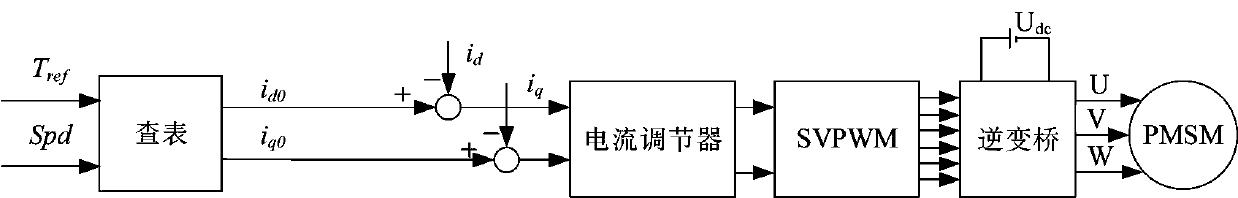

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] Step 1, calibrate the rotational speed point of the permanent magnet synchronous motor.

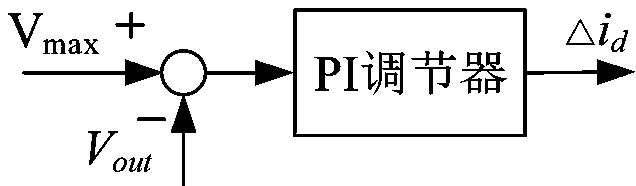

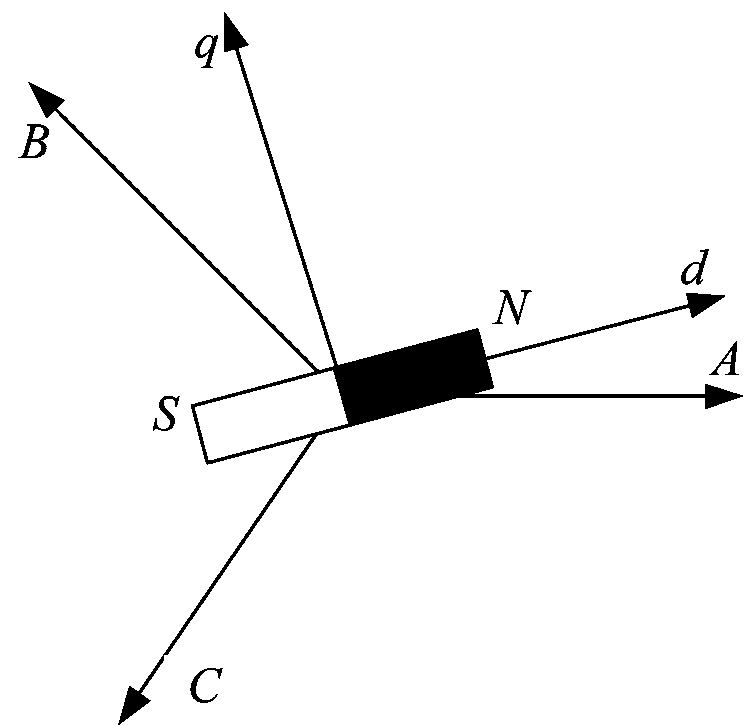

[0031] Adjust the angle between the D-axis current and the Q-axis current at the same current amplitude, so that the output motor torque reaches the maximum. At this time, to find the point of the maximum torque-current ratio of the permanent magnet synchronous motor, record the motor speed and rotation speed at this time. Moment, as well as D-axis current and Q-axis current given value, and then adjust the current given amplitude according to a certain ratio.

[0032] Divide different speed points, and use the same method to find the D-axis / Q-axis current distribution method with the highest motor efficiency, record the next set of data, and calibrate the next speed point when the motor reaches the maximum torque or maximum power. And so on until the maximum spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com