Integrated molding machining system

A molding processing and turntable technology, applied in the field of integrated molding processing systems, can solve problems such as low work efficiency, poor stability, and short service life, and achieve the effects of saving manpower, good product quality, and strengthening integration and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

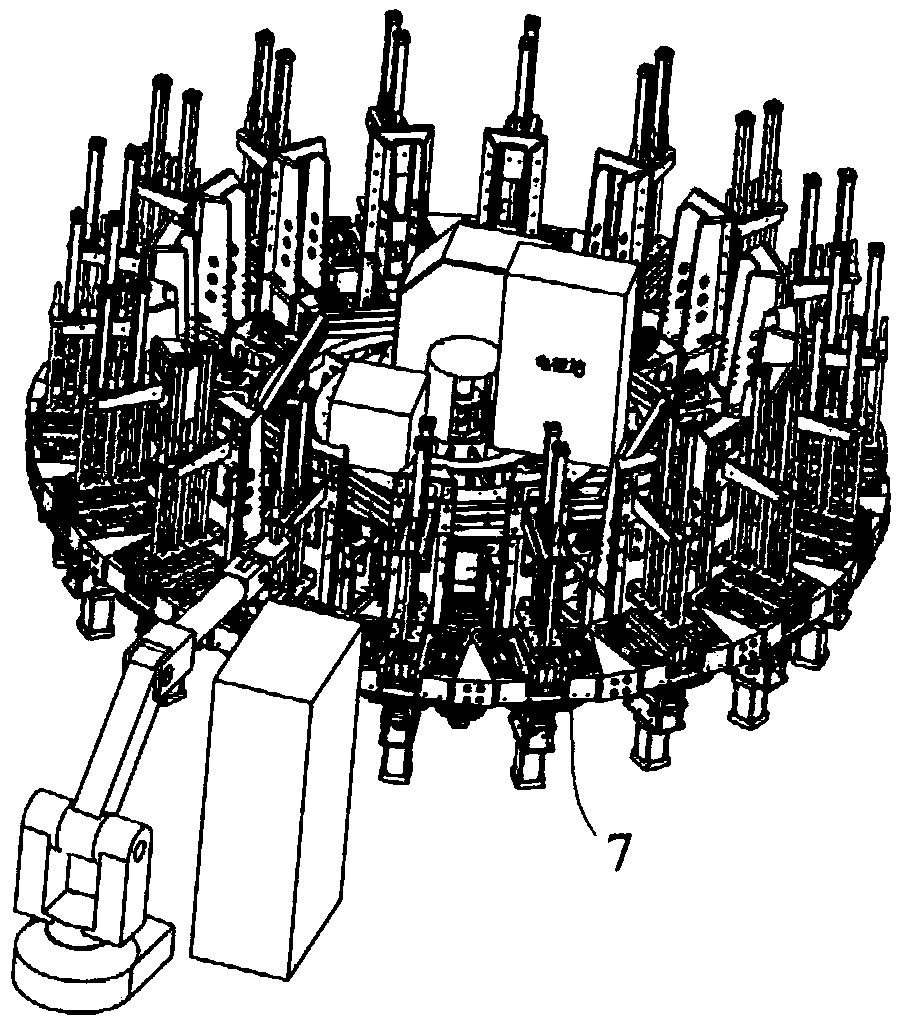

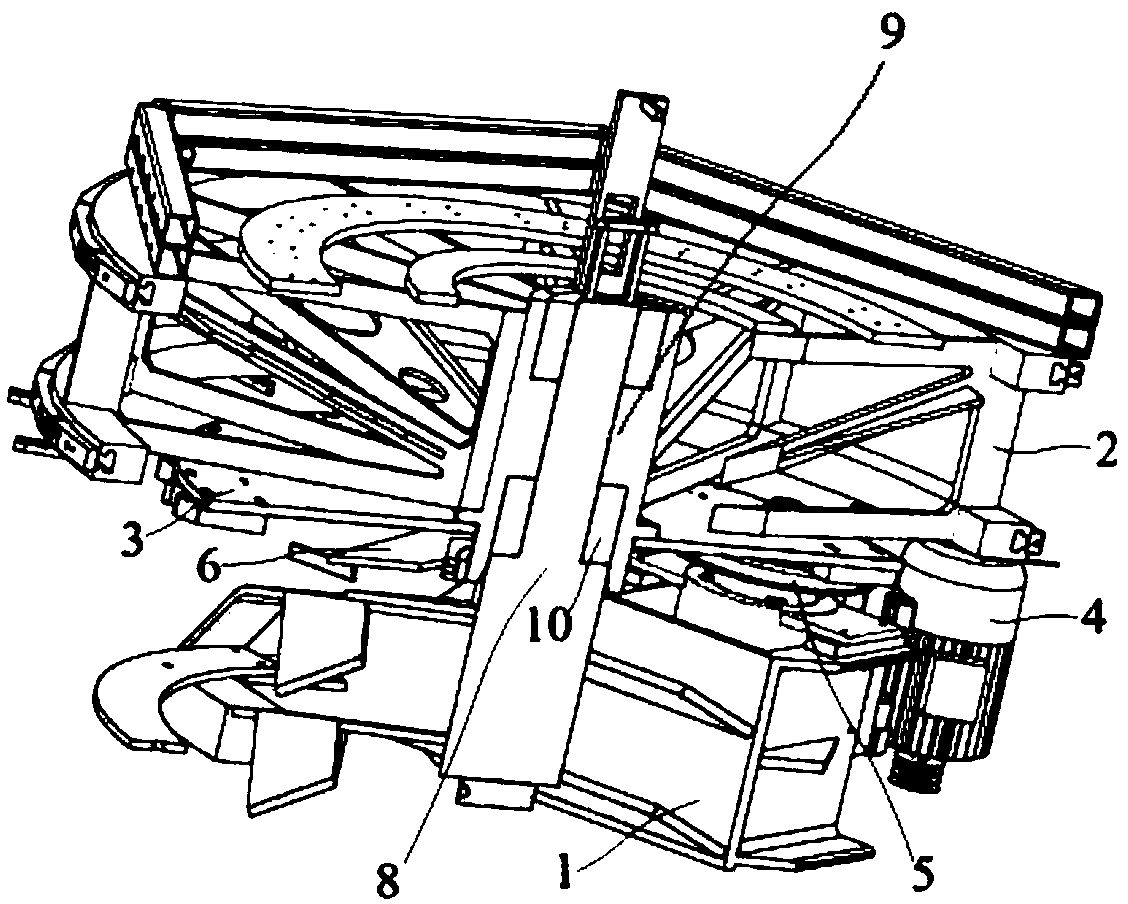

[0041] Embodiment 1: An integrated molding processing system, including a base 1, a turntable 2, a turntable 3, a motor 4, a drive turntable 5, a brake assembly 6 and several injection molding mechanisms 7, and the turntable 2 is rotatably mounted on the base 1, the turntable 3 is installed and connected with the turntable 2 to drive the turntable 2 to rotate, the motor 4 is installed on the base 1, the motor 4 is connected to the drive turntable 5, and the brake assembly 6 is installed on the base 1, used to brake the turntable 2, and the plurality of injection molding mechanisms 7 are installed on the turntable 2 at equal intervals in the circumferential direction;

[0042] The upper surface of the driving turntable 5 is provided with two circular protrusions 18, and the lower surface of the turntable 3 is provided with several pairs of clamping strips 17, and a strip for the insertion of the circular projections 18 is formed between each pair of clamping strips 17. Shaped g...

Embodiment 2

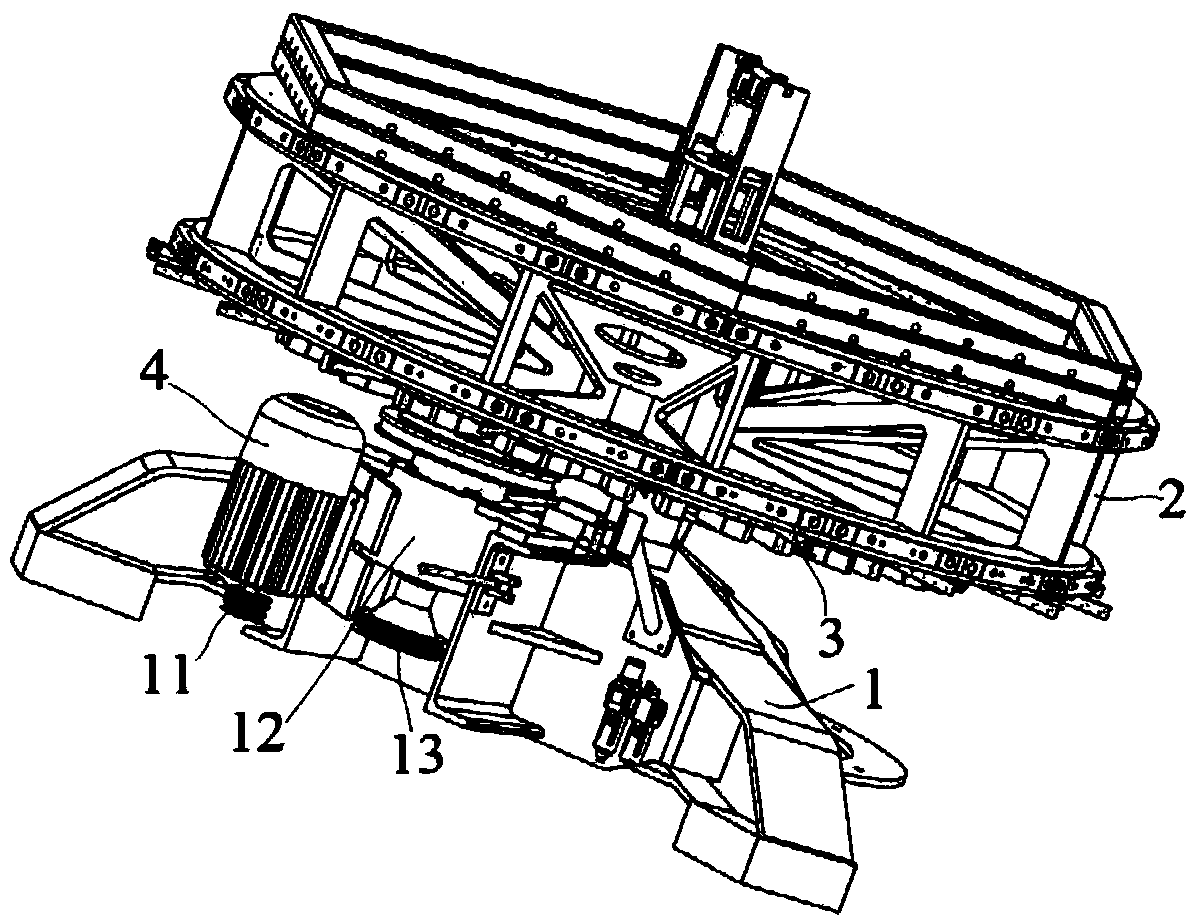

[0052] Embodiment 2: An integrated molding processing system, including a base 1, a turntable 2, a turntable 3, a motor 4, a drive turntable 5, a brake assembly 6 and several injection molding mechanisms 7, and the turntable 2 is rotatably mounted on the base 1, the turntable 3 is installed and connected with the turntable 2 to drive the turntable 2 to rotate, the motor 4 is installed on the base 1, the motor 4 is connected to the drive turntable 5, and the brake assembly 6 is installed on the base 1, used to brake the turntable 2, and the plurality of injection molding mechanisms 7 are installed on the turntable 2 at equal intervals in the circumferential direction;

[0053] The upper surface of the driving turntable 5 is provided with two circular protrusions 18, and the lower surface of the turntable 3 is provided with several pairs of clamping strips 17, and a strip for the insertion of the circular projections 18 is formed between each pair of clamping strips 17. Shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com