A continuous casting process for medium-carbon structural steel with low-sulfur content directly in converter

A medium-thin slab continuous casting, low sulfur content technology, applied in the field of metallurgy, can solve problems such as inability to pour and product quality cannot meet requirements, achieve good product quality, solve nozzle nodules and product surface defects, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

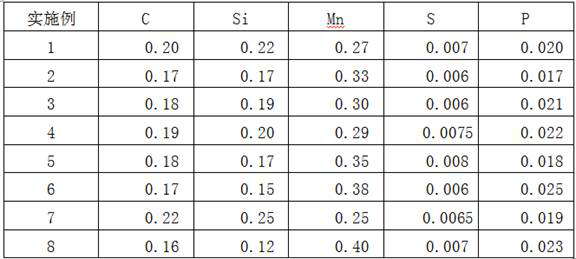

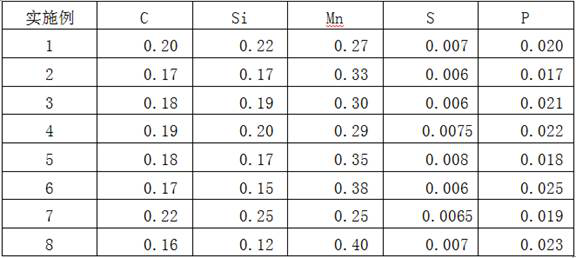

Examples

Embodiment 1

[0033] In this embodiment, the process of continuous casting of medium and thin slabs directly on the carbon structural steel converter includes the following steps:

[0034] (1) Hot metal pretreatment process: the temperature of hot metal before treatment is 1270°C, S: 0.032%; using the magnesium powder injection process, 4 kg / t of lime powder is added to the iron ladle in advance, and the S in hot metal after desulfurization: 0.009%, Remove the iron slag after desulfurization;

[0035] (2) Converter smelting process:

[0036] A. The ladle is required to use red envelopes continuously, and it is forbidden to place the first three furnaces and the furnace ladle for major repairs and spare ladles. The time for the ladle to be used is 50 minutes from the continuous casting stop to the converter tapping;

[0037] B. Converter smelting cycle, that is, from the beginning of iron loading to the completion of tapping is 27 minutes; the cycle of argon blowing treatment is 13 minutes;...

Embodiment 2

[0043] In this embodiment, the process of continuous casting of medium and thin slabs directly on the carbon structural steel converter includes the following steps:

[0044] (1) Hot metal pretreatment process: the temperature of hot metal before treatment is 1265 ° C, S: 0.030%; using the magnesium powder injection process, 6 kg / t steel lime powder is added in advance to the iron ladle, and S in hot metal after desulfurization: 0.007%, Remove the iron slag after desulfurization;

[0045] (2) Converter smelting process:

[0046] A. The ladle is required to use red envelopes continuously, and it is forbidden to place the first three furnaces and the furnace ladle for major repairs and spare ladles. The time for the used ladle from continuous casting to converter tapping is 45 minutes;

[0047] B. Converter smelting cycle, that is, 26 minutes from the beginning of iron loading to the completion of tapping; 11 minutes of argon blowing treatment cycle; 6 minutes of hanging bag ...

Embodiment 3

[0053] In this embodiment, the process of continuous casting of medium and thin slabs directly on the carbon structural steel converter includes the following steps:

[0054] (1) Hot metal pretreatment process: the temperature of hot metal before treatment is 1280°C, S: 0.025%; using the magnesium powder injection process, 3 kg / t steel lime powder is added in advance in the iron ladle, and S in hot metal after desulfurization: 0.006%, Remove the iron slag after desulfurization;

[0055] (2) Converter smelting process:

[0056] A. The ladle is required to use red envelopes continuously, and it is forbidden to place the first three furnaces and the furnace ladle for major repairs and spare ladles. The time for the ladle used is 54 minutes from the continuous casting stop to the converter tapping;

[0057] B. Converter smelting cycle, that is, 26 minutes from the beginning of iron loading to the completion of tapping; the argon blowing treatment cycle is 12 minutes; the hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com