Cold-rolled steel sheet for automobile silencer and production method of cold-rolled steel sheet

A technology of cold-rolled steel sheet and production method, which is applied in the field of iron-based alloys, can solve the problems of high manufacturing cost and unstable material properties, and achieves the effects of satisfying high shape requirements, optimizing reduction ratio, and improving steel shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

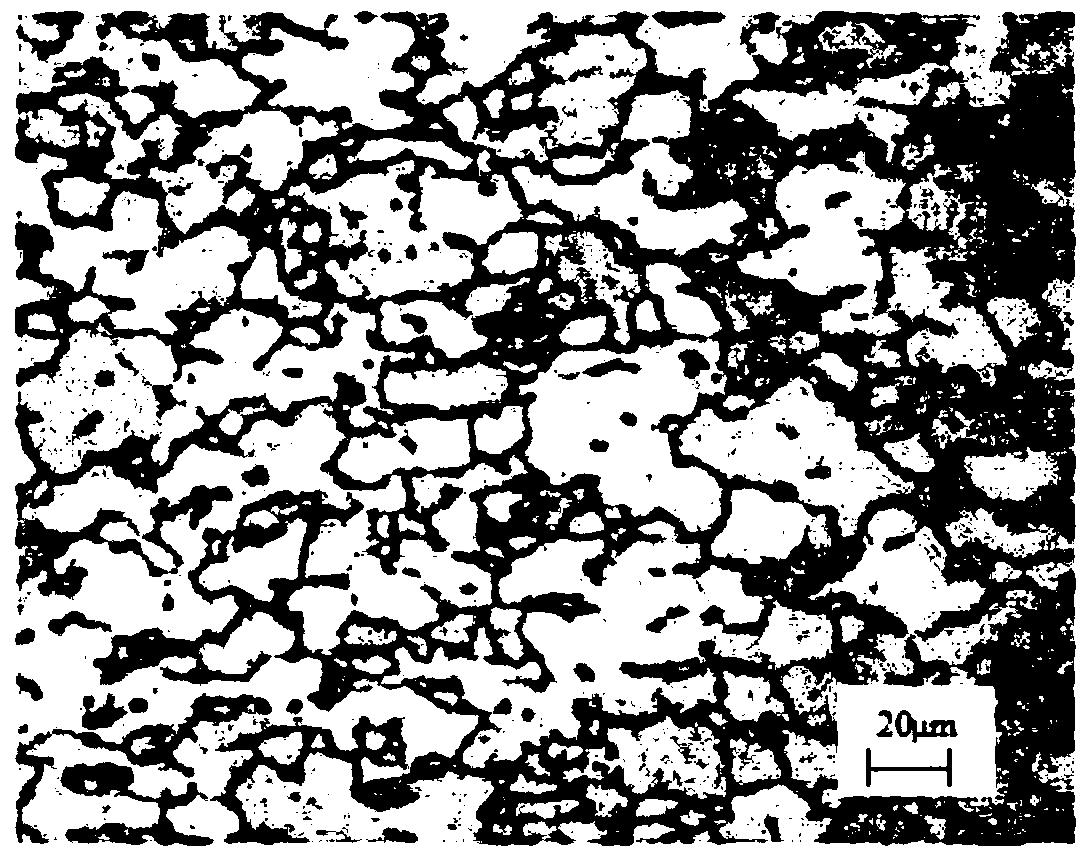

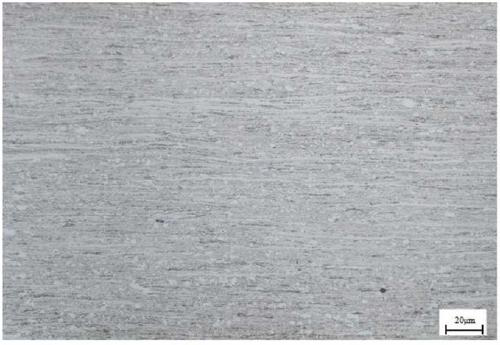

Image

Examples

Embodiment Construction

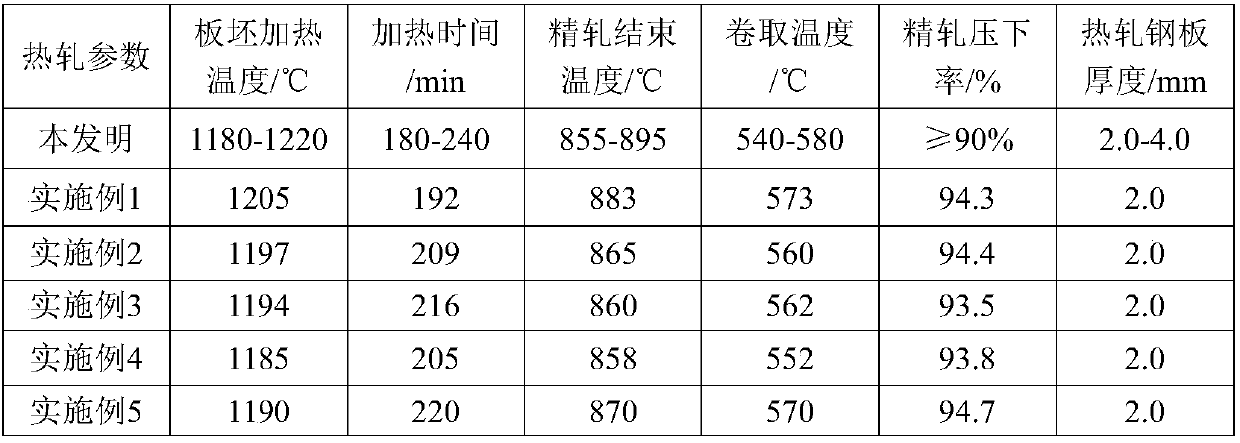

[0043] The present invention will be further described below in conjunction with specific examples 1-5, as shown in Table 1-4, Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0044] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0045] element C Si mn P S Al this invention 0.05-0.07 ≤0.034 0.2-0.3 ≤0.018 ≤0.0164 0.01-0.04 Example 1 0.0589 0.0056 0.2324 0.0145 0.0088 0.022 Example 2 0.0588 0.007 0.2406 0.0152 0.0113 0.018 Example 3 0.0654 0.0081 0.2385 0.0154 0.0084 0.038 Example 4 0.068 0.0065 0.2438 0.0142 0.0084 0.027 Example 5 0.558 0.0095 0.2815 0.0128 0.0093 0.012

[0046] The molten steel that meets the basic requirements of the chemical composition is obtained through converter smelting. After the molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com