Method for reducing chromatic aberration of cold rolled dual-phase steel

A dual-phase steel, color difference technology, applied in metal rolling, temperature control and other directions, can solve the problems of cold-rolled dual-phase steel color difference, etc., to achieve the effect of low strip temperature, reduced color difference, and optimized cold rolling reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Take the production of galvanized DP780 with a specification of 0.8mm*1480mm as an example. The smelting components for producing DP780 are specifically carbon C with a mass ratio of 0.145% to 0.165%, silicon Si at 0.45% to 0.55%, manganese Mn at 1.85% to 1.95%, phosphorus P less than or equal to 0.015%, and phosphorus P less than or equal to 0.007%. Sulfur S, 0.02% to 0.07% of aluminum Al, 0.25% to 0.35% of chromium Cr and less than or equal to 0.005% of nitrogen N.

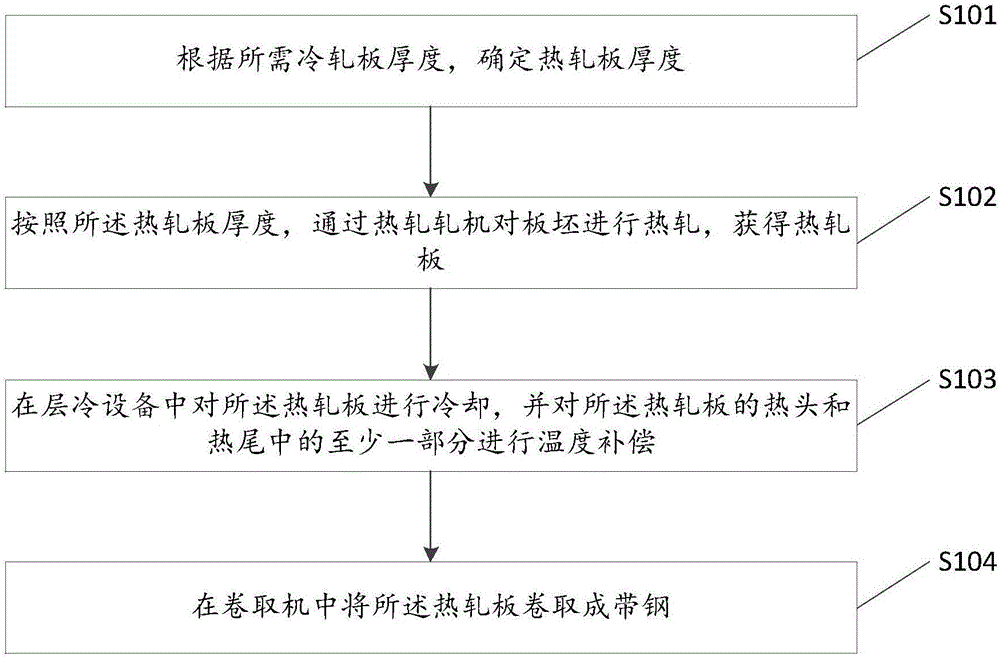

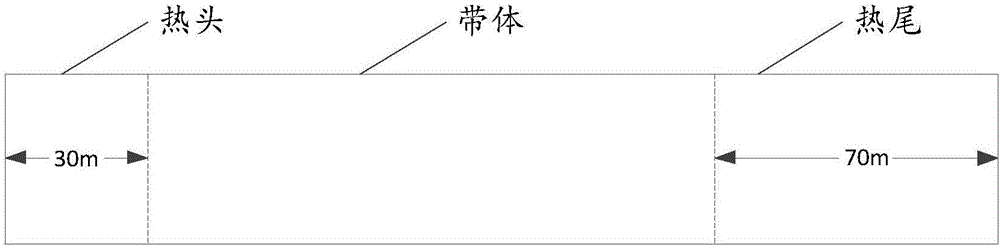

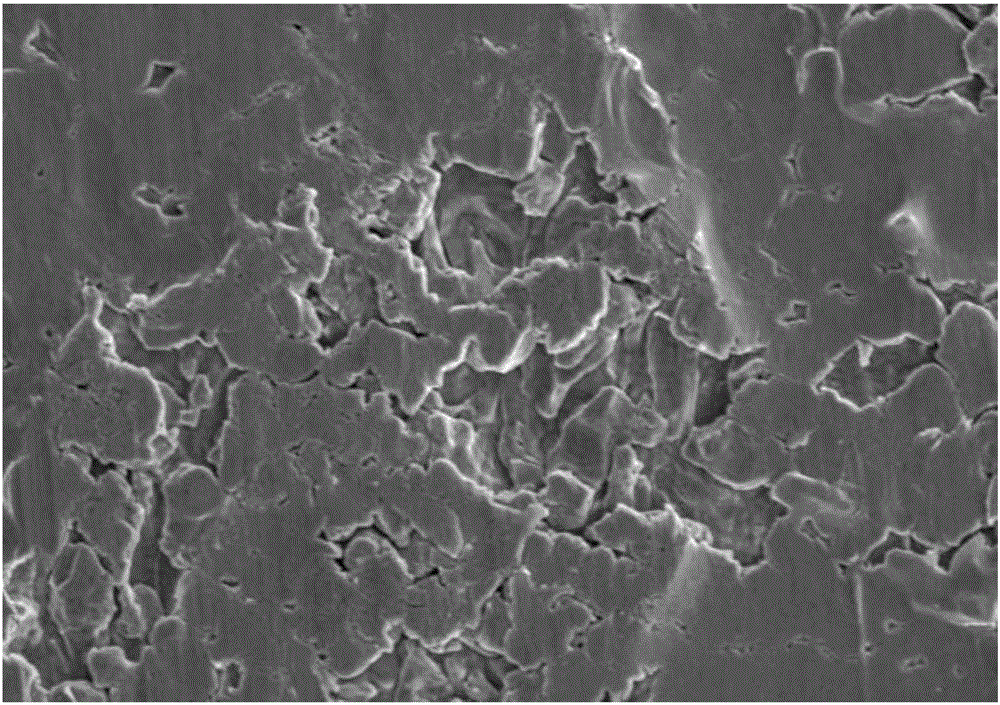

[0067] Set the thickness of the hot-rolled sheet to 2.75mm. After the hot-rolled sheet is rolled to 2.75mm, the temperature compensation of the 30m part of the hot head and the 70m part of the hot tail is carried out at 30°C in the layer cooling equipment, and then the coiler is coiled The temperature is 550°C and coiled into rolls. Finally, galvanized DP780 is finally obtained through cold rolling process. image 3 shows a prior art galvanized DP780 surface, Figure 4 The surface of galvanized DP780 i...

Embodiment 2

[0069] Take the continuous retreat HC380 / 700DP with a production specification of 2.0mm*1048mm as an example. The smelting components for the production of continuous annealing HC380 / 700DP are specifically 0.08% to 0.10% C by mass ratio, 1.10% to 1.20% Si, 1.9% to 2.0% Mn, less than or equal to 0.020% of P, and less than or equal to 0.007% of S , 0.020% to 0.060% of Al, 0.020% to 0.060% of Cr and less than or equal to 0.005% of N.

[0070] Set the thickness of the hot-rolled sheet to 4mm. After the hot-rolled sheet is rolled to 4mm, the temperature compensation of the 30m part of the hot head and the 70m part of the hot tail is performed at 30°C in the layer cooling equipment, and then the coiling temperature is 520°C after passing through the coiler. ℃ coiled into rolls. Finally, the continuous annealing HC380 / 700DP is finally obtained through the cold rolling process. Figure 5 Shows the prior art continuous retreat HC380 / 700DP surface, Image 6 The surface of the continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com