A method for reducing the color difference of cold-rolled dual-phase steel

A dual-phase steel and color difference technology, applied in metal rolling, temperature control, etc., can solve the problems of cold-rolled dual-phase steel color difference, etc., and achieve the effect of low strip temperature, reduced transverse shear force, and reduced color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

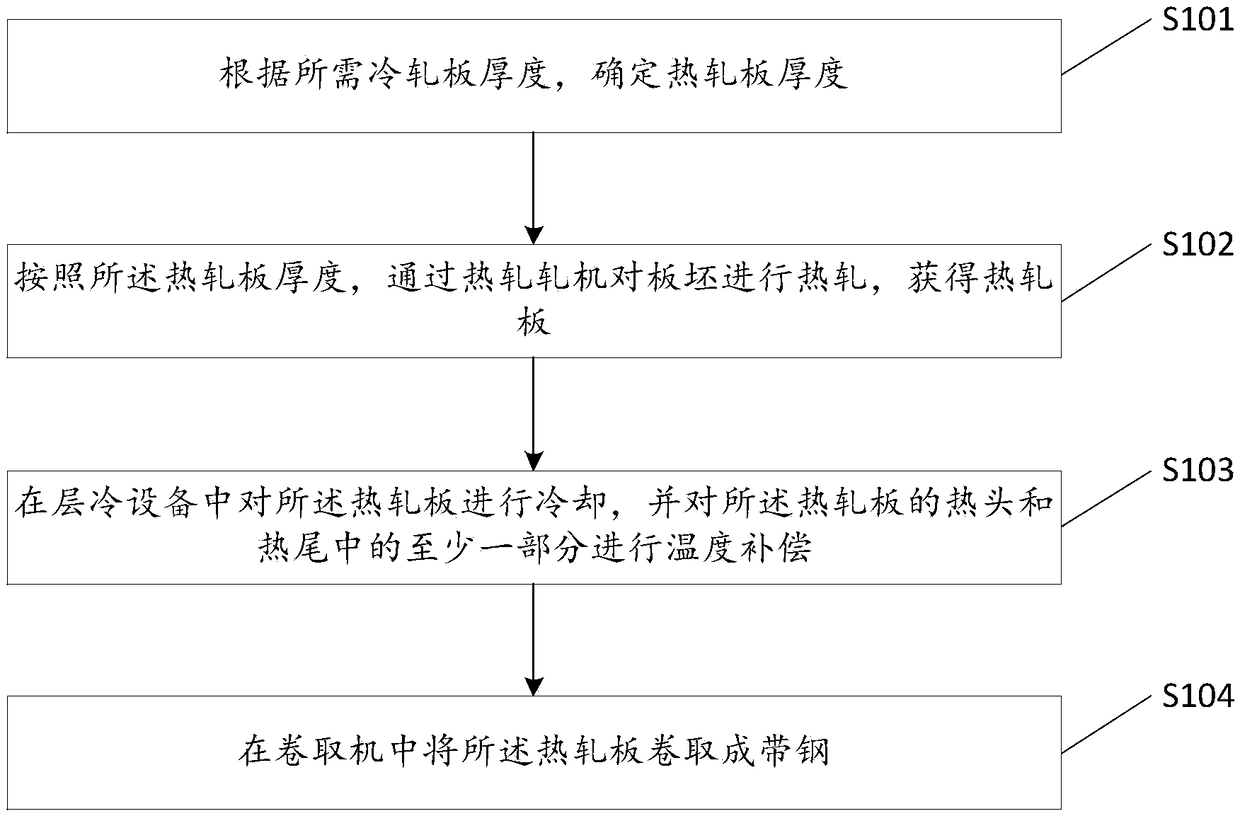

Method used

Image

Examples

Embodiment 1

[0066] Take galvanized DP780 with a production specification of 0.8mm*1480mm as an example. The smelting composition for producing DP780 is specifically carbon C with a mass ratio of 0.145% to 0.165%, silicon Si of 0.45% to 0.55%, manganese Mn of 1.85% to 1.95%, phosphorus P of less than or equal to 0.015%, and phosphorus of less than or equal to 0.007%. Sulfur S, 0.02% to 0.07% of aluminum Al, 0.25% to 0.35% of chromium Cr and 0.005% or less of nitrogen N.

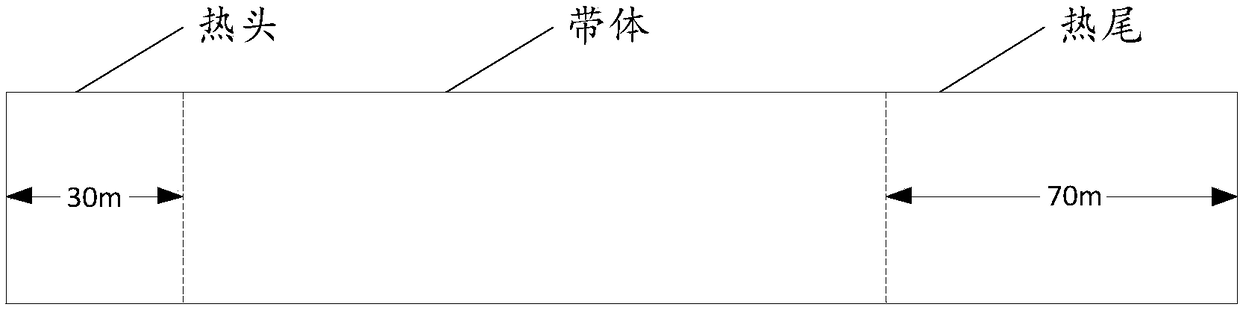

[0067] The thickness of the hot-rolled sheet is set to 2.75mm, and after rolling the hot-rolled sheet to 2.75mm, the temperature compensation of 30°C is performed on the 30m part of the hot head and the 70m part of the hot tail in the layer cooling equipment, and then the coil is passed through the coiler to coil. The temperature is 550°C and coiled into rolls. Finally, the galvanized DP780 is finally obtained through the cold rolling process. image 3 A prior art galvanized DP780 surface is shown, Figure 4 The galvan...

Embodiment 2

[0069] Take the continuous retreat HC380 / 700DP with a production specification of 2.0mm*1048mm as an example. The smelting composition of HC380 / 700DP in production continuous retreat is 0.08%-0.10% C, 1.10%-1.20% Si, 1.9%-2.0% Mn, 0.020% or less P, and 0.007% or less S. , 0.020% to 0.060% of Al, 0.020% to 0.060% of Cr and less than or equal to 0.005% of N.

[0070] Set the thickness of the hot-rolled sheet to 4mm, and after rolling the hot-rolled sheet to 4mm, the temperature compensation of 30 m of the hot head and 70 m of the hot tail is carried out in the layer cooling equipment, and then the coiling temperature is 520 °C after passing through the coiling machine. ℃ Coiled into rolls. Finally, through the cold rolling process, the continuous withdrawal HC380 / 700DP is finally obtained. Figure 5 Shows the prior art continuation HC380 / 700DP surface, Image 6 The second embodiment shows that the surface of HC380 / 700DP is continuously retreated. It can be seen that the color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com