High-temperature salt bath furnace deoxidizing agent and deoxidizing method thereof

A high-temperature salt and deoxidizer technology, applied in heat treatment baths, heat treatment equipment, manufacturing tools, etc., can solve problems such as decarburization and surface oxidation of parts, achieve low cost, convenient procurement, and eliminate surface oxidation and decarburization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A high-temperature salt bath furnace deoxidizer is composed of the following parts by mass of raw materials: 65 parts of titanium dioxide; 35 parts of silica gel.

[0017] A method for deoxidizing the deoxidizer of a high temperature salt bath furnace adopts the following steps:

[0018] a. Raise the high temperature salt bath furnace to 1300℃;

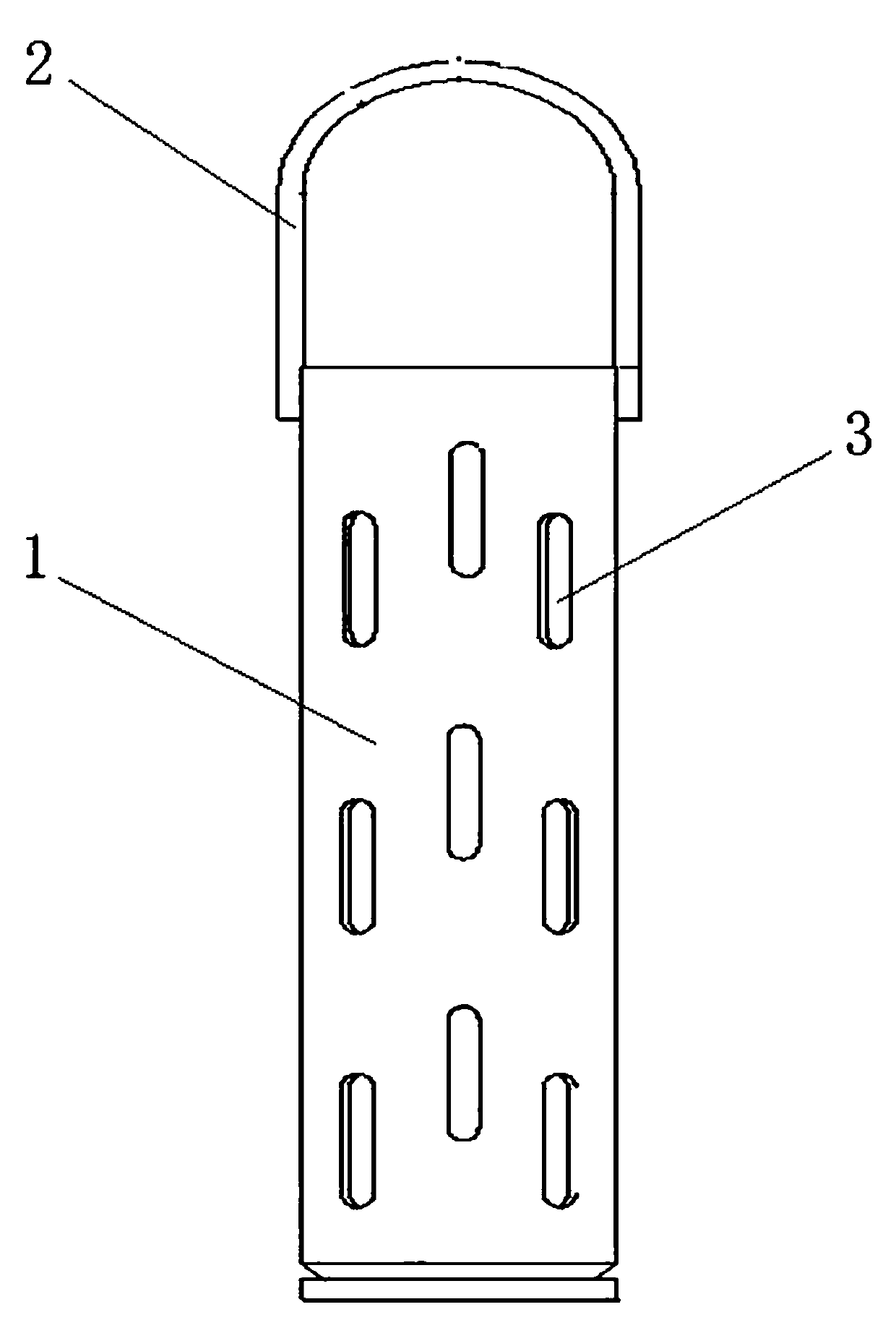

[0019] b. The reaction cage is made of stainless steel. The reaction cage includes a cylindrical cage 1. The upper end of the cylindrical cage 1 is provided with a lifting handle 2. The cylindrical surface and the bottom surface of the cylindrical cage 1 have several liquid inlets 3, and the cylindrical cage The inner wall of the bottom surface of the body 1 is provided with tin foil;

[0020] c. Put the deoxidizer into the reaction cage, and then slowly enter the reaction cage into the middle of the salt bath of the high temperature salt bath furnace for reaction. After the reaction is over, take out the reaction cage and stir evenly ...

Embodiment 2

[0025] A high-temperature salt-bath furnace deoxidizer is composed of the following parts by mass: 67 parts of titanium dioxide; 33 parts of silica gel.

[0026] A method for deoxidizing the deoxidizer of a high temperature salt bath furnace adopts the following steps:

[0027] a. Raise the high temperature salt bath furnace to 1310℃;

[0028] b. The reaction cage is made of stainless steel. The reaction cage includes a cylindrical cage 1. The upper end of the cylindrical cage 1 is provided with a lifting handle 2. The cylindrical surface and the bottom surface of the cylindrical cage 1 have several liquid inlets 3, and the cylindrical cage The inner wall of the bottom surface of the body 1 is provided with tin foil;

[0029] c. Put the deoxidizer into the reaction cage, and then slowly enter the reaction cage into the middle of the salt bath of the high temperature salt bath furnace for reaction. After the reaction is over, take out the reaction cage and stir evenly with a stainless ...

Embodiment 3

[0034] A high-temperature salt bath furnace deoxidizer is composed of the following parts by mass: 59 parts of titanium dioxide; 41 parts of silica gel.

[0035] A method for deoxidizing the deoxidizer of a high temperature salt bath furnace adopts the following steps:

[0036] a. Raise the high temperature salt bath furnace to 1290℃;

[0037] b. The reaction cage is made of stainless steel. The reaction cage includes a cylindrical cage 1. The upper end of the cylindrical cage 1 is provided with a lifting handle 2. The cylindrical surface and the bottom surface of the cylindrical cage 1 have several liquid inlets 3, and the cylindrical cage The inner wall of the bottom surface of the body 1 is provided with tin foil;

[0038] c. Put the deoxidizer into the reaction cage, and then slowly enter the reaction cage into the middle of the salt bath of the high temperature salt bath furnace for reaction. After the reaction is over, take out the reaction cage and stir evenly with a stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com