Tubular braid manufacturing equipment

A technology for manufacturing equipment and braids, which is applied in the field of tubular braids manufacturing equipment, can solve the problems of unsatisfactory market demand, single types of braids, complex transmission structure, etc., and achieve simple structure, high-efficiency weaving requirements, and simple transmission structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0028]

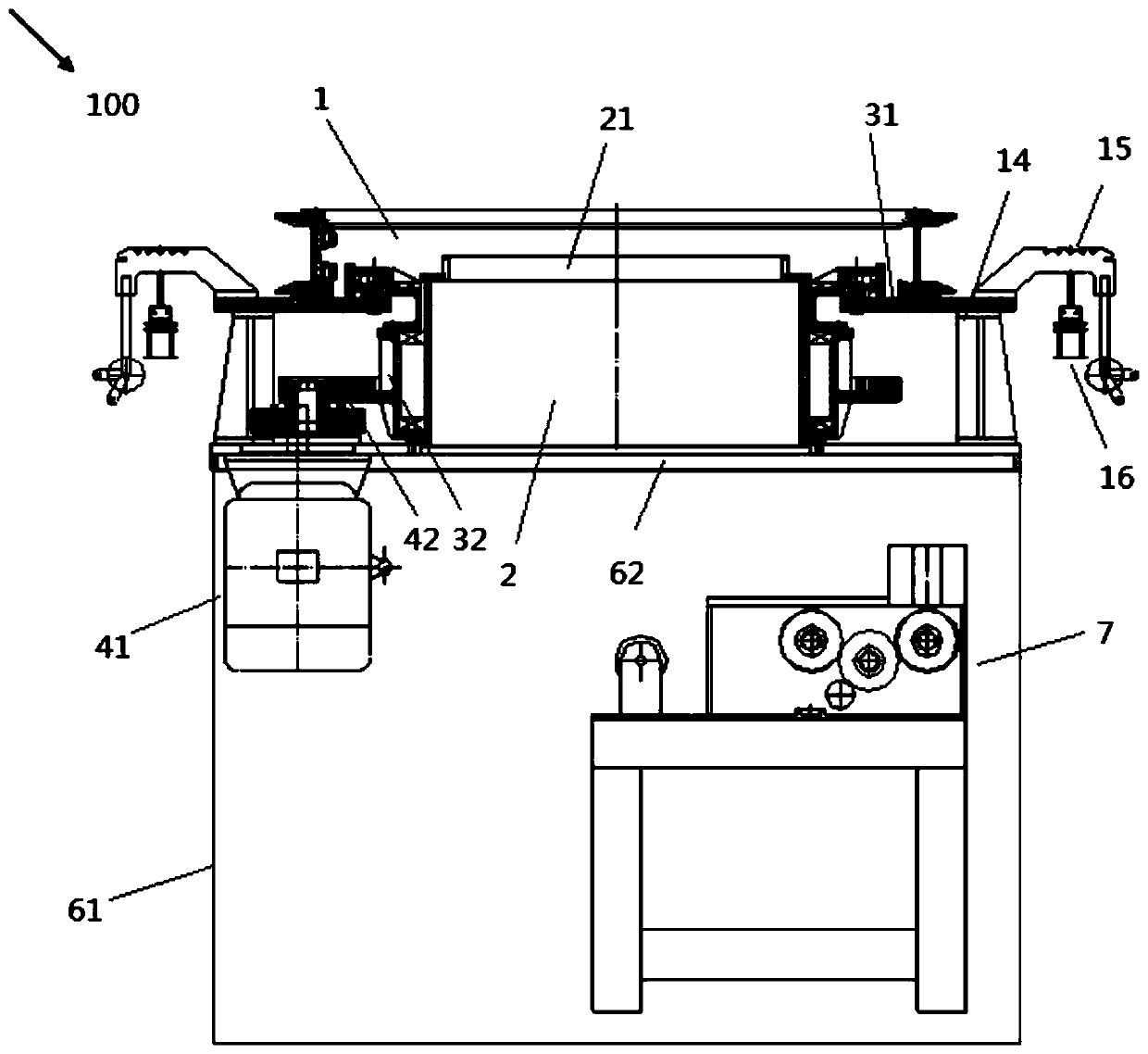

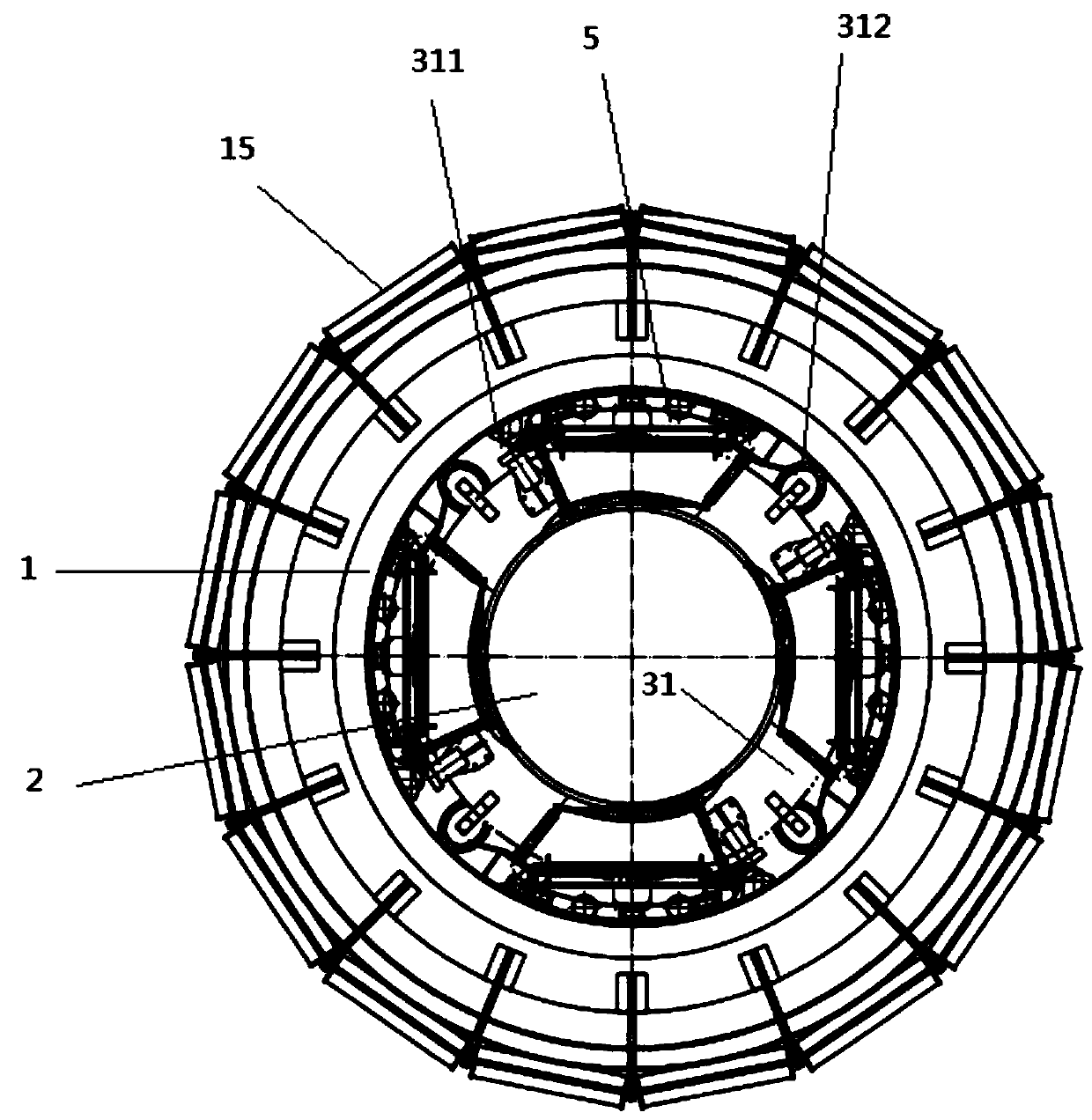

[0029] figure 1 is an overall structural diagram of the tubular braid manufacturing equipment of the embodiment of the present invention, figure 2 It is a top view of a cylindrical braid manufacturing equipment in an embodiment of the present invention.

[0030] Such as figure 1 and figure 2 As shown, the cylindrical braided fabric manufacturing equipment 100 of this embodiment is used to knit multi-ply yarns to obtain cylindrical braided fabrics, and has an annular frame body 1, a braided fabric guide cylinder 2, a rotary part 3, and a driving part 4. The shuttle 5 and the supporting part 6.

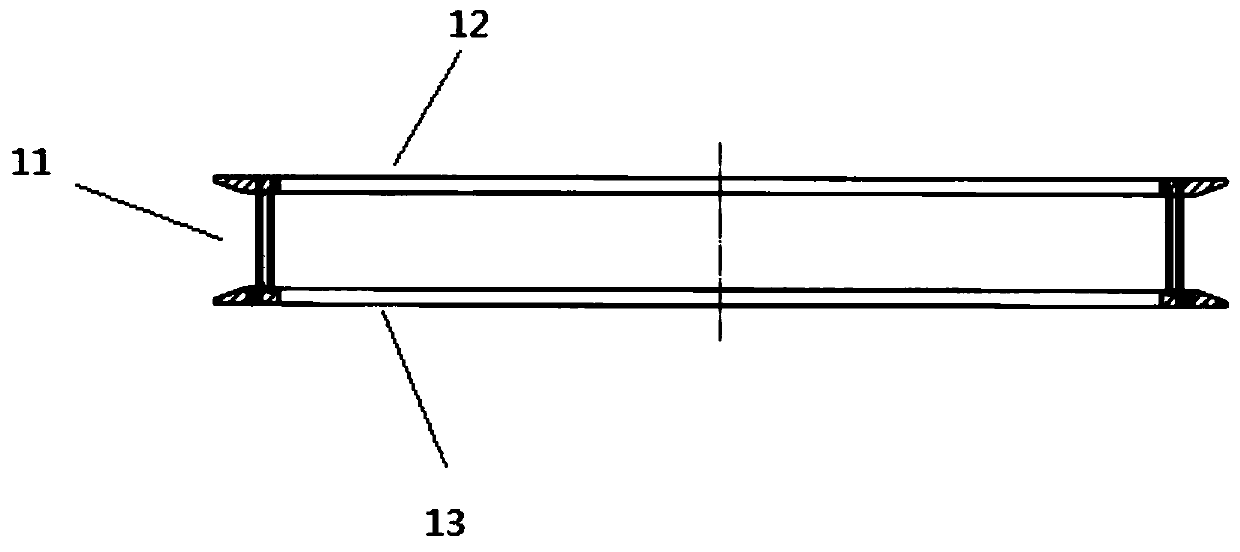

[0031] image 3 It is a sectional view of the annular frame body in the embodiment of the present invention, Figure 4 It is a top view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com