A method for switching between the whole barrel pump and the gas lift pumping method without unloading the casing pressure

A technology of gas lift and casing unloading, which is applied in the direction of casing, mining fluid, earthwork drilling, etc., and can solve the problem that the whole barrel pump cannot meet the production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

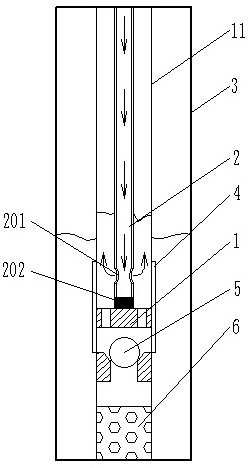

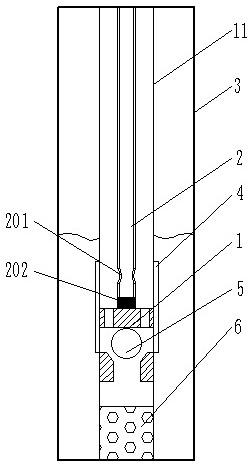

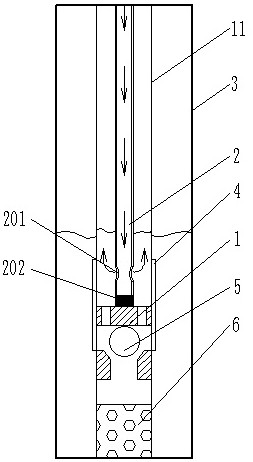

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021] A method for switching between a full cylinder pump and a gas lift extraction method without releasing casing pressure, specifically comprising the following steps:

[0022] 1) Move the workover locomotive to the coalbed methane workover site, erect the workover derrick, erect the oil pipe bridge (for placing the oil pipe 11 and sucker rod), and dismantle the instrument.

[0023] 2) Remove the polished rod sealing box 9 (to seal the space between the polished rod and the oil pipe), and lift the sucker rod and pump cylinder plunger in the oil pipe 11.

[0024] 3) if figure 1 As shown, the hollow sucker rod 2 equipped with a strong magnet 202 at the tail end and having a transverse through hole 201 is lowered from the oil pipe mouth to the bottom of the pump barrel 4 to fix the upper part of the valve base 5, and the hollow sucker rod is sealed with a polished rod sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com